Automatic design method for ship segmental hoisting scheme

A segmented hoisting and scheme technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as low efficiency, waste of materials, economy, safety and ease of operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

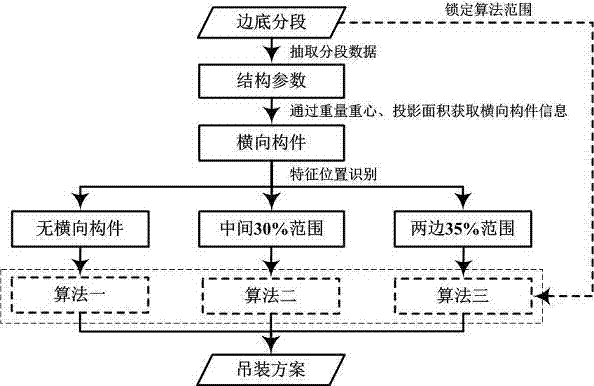

[0044] The method steps of the present invention are described below:

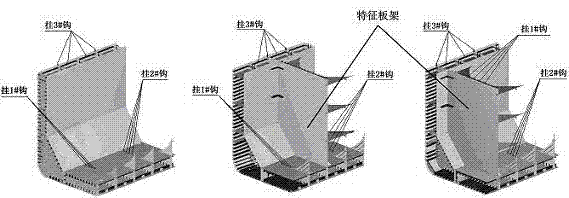

[0045] Such as Figure 1-4 As shown, an automatic design method for a ship segment hoisting scheme includes the following steps:

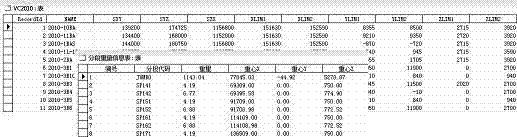

[0046] The first step: Select the hoisting segment model: including the establishment of a model library containing multiple segment models and an initial algorithm library associated with each segment model including initialization hoisting algorithms of various typical segment types; from the model library Select the segment model corresponding to the ship segment to be hoisted, and the initialization hoisting algorithm associated with the selected segment model in the initial algorithm library is selected; the structure in the selected segment model is extracted by the Tribon system parameter information, and store the structural parameter information in the background database; the structural parameter information includes structural size parameters and weight center of gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com