GaAs double-faced thin-film solar cell

A technology of solar cells and thin films, applied in the field of solar cells, can solve problems such as low efficiency, low energy density of cell arrays, and damage to cell structures, and achieve the effects of large output power per unit area, improved photoelectric conversion efficiency, and reduced light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

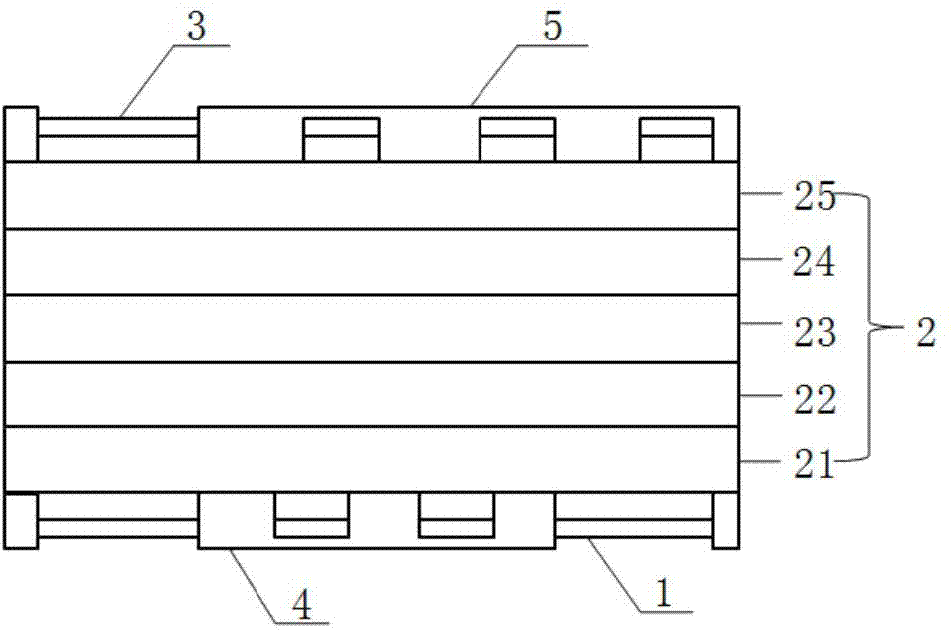

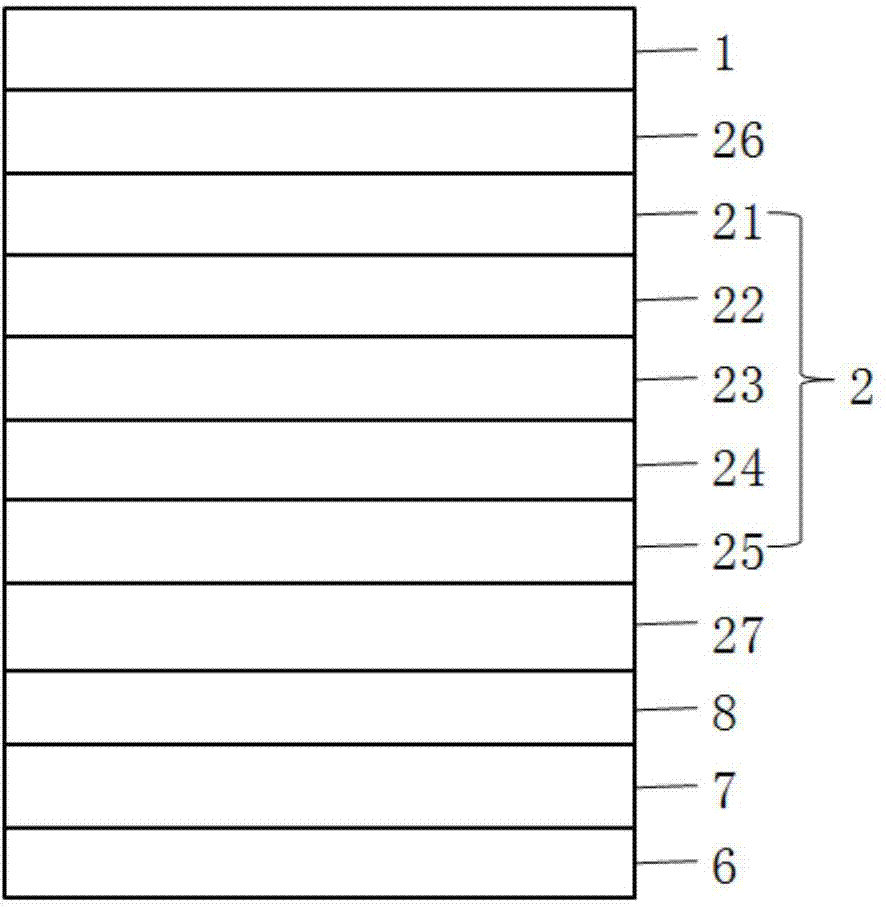

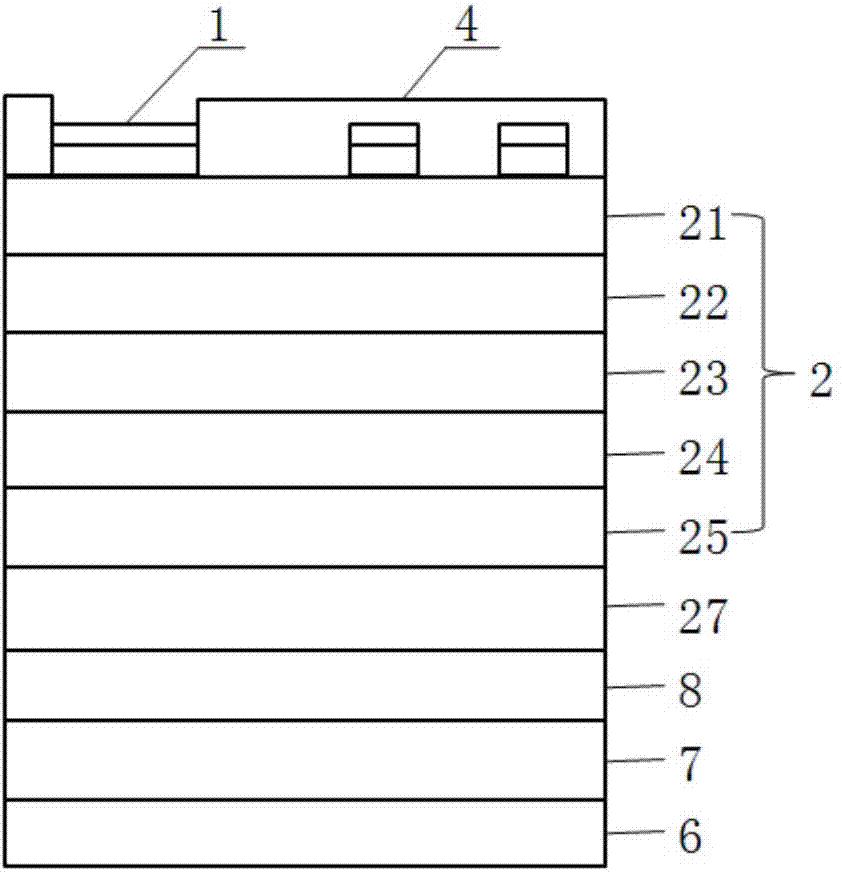

[0055] This embodiment provides a GaAs double-sided thin-film solar cell, such as figure 1 with Figure 13-14 As shown, it is a rectangular thin-film solar battery unit, and the diagonal length of the rectangular battery unit is 4 inches or 6 inches; it includes a back electrode layer 1, a device layer 2 and a gate electrode layer 3;

[0056] The gate electrode layer 3 has a first grid line structure, the first grid line structure includes a part of the edge busbar 11 arranged on one side of the battery cell, and the part of the edge busbar 11 is only arranged on one side of the battery cell The side has good current collection efficiency, and it also includes a first pair arranged inside the gate electrode layer 3, one end of which is connected to the part of the edge main grid line 11 and extends to the other side of the battery cell. grid lines 12; the width of the partial edge main grid lines 11 is 1 mm; the width of the first sub grid lines 12 is 0.1 mm, and the distance...

Embodiment 2

[0073] This embodiment provides a GaAs double-sided thin-film solar cell, such as figure 1 with Figure 10-12 As shown, it is an array composed of regular hexagonal thin film solar cell units, the side length of the regular hexagonal thin film solar cell unit is 2 inches, and the distance between two adjacent regular hexagonal solar cell units in the array is 500 μm, Each of the thin film solar cell units includes a back electrode layer 1, a device layer 2 and a gate electrode layer 3;

[0074] The gate electrode layer 3 has a first grid line structure, the first grid line structure includes part of the edge busbars 11 arranged on opposite sides of the battery cell, and the part of the edge busbars 11 is only arranged on the battery cell Good current collection efficiency is obtained on both sides of the cell, and it also includes a gate electrode layer 3 disposed inside, one end connected to the part of the edge busbar 11 provided and extended to the other side of the batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com