OLED (Organic Light Emitting Diode) packaging structure and method

A packaging structure and packaging method technology, applied in the direction of organic semiconductor devices, electrical components, electrical solid devices, etc., can solve the problems of not being suitable for large-size panels, affecting display effects, and panel bending, so as to avoid uneven display brightness and increase The effect of bonded area, good sealing and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

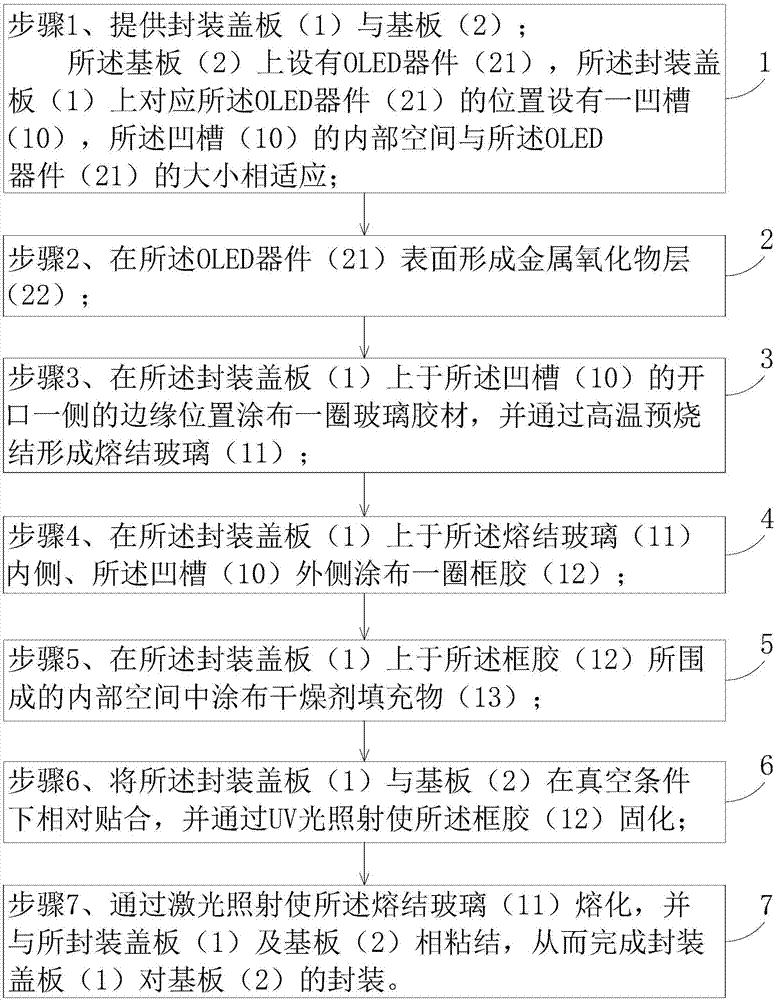

[0036] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

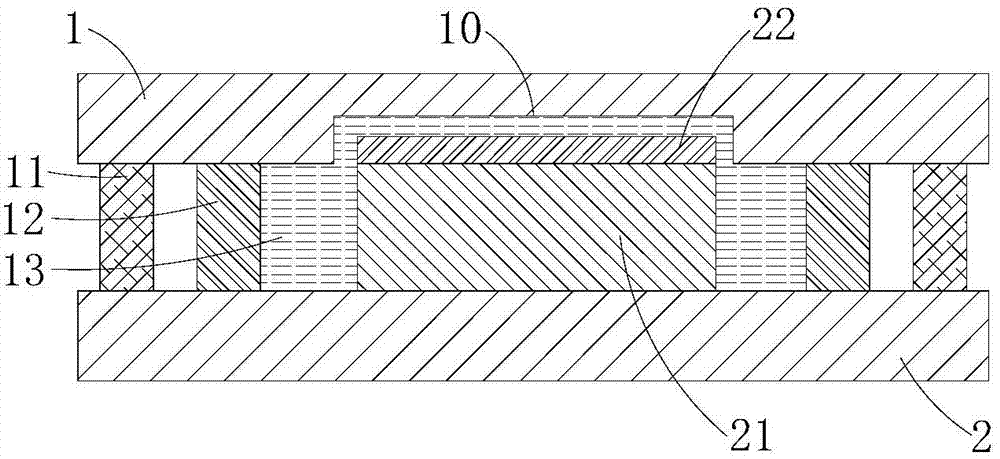

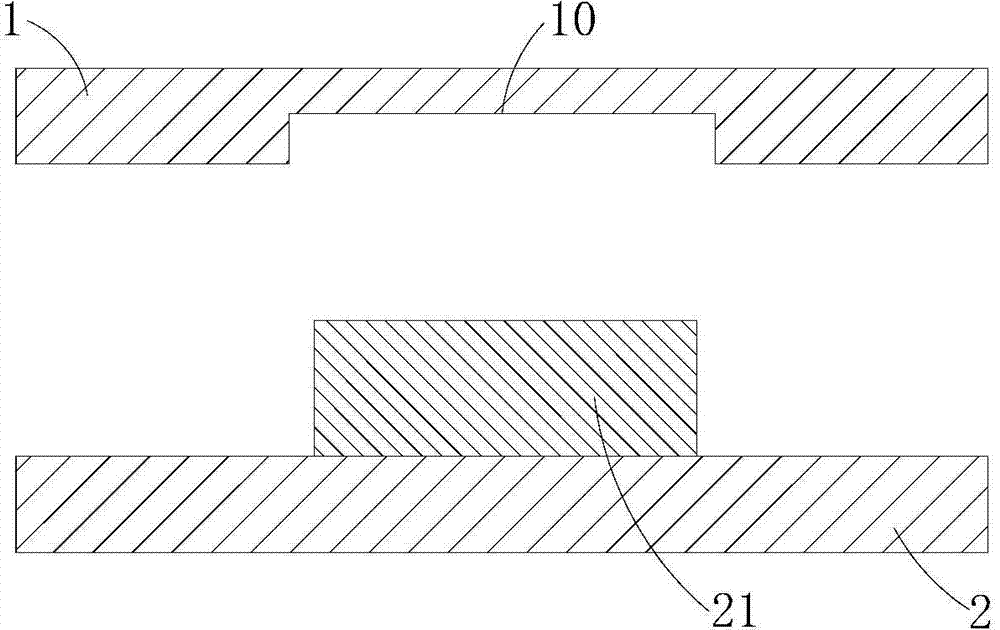

[0037] Such as figure 1 As shown, the present invention provides an OLED packaging structure, including a packaging cover plate 1, a substrate 2 disposed opposite to the packaging cover plate 1, located between the packaging cover plate 1 and the substrate 2 and arranged on the substrate 2 The OLED device 21 on the surface, the metal oxide layer 22 formed on the surface of the OLED device 21, the sealant 12 provided on the periphery of the OLED device 21 to bond the package cover 1 and the substrate 2, and fill the package cover The inner space surrounded by the sealant 12 between the plate 1 and the substrate 2 covers the desiccant filler 13 of the OLED device 21, and is arranged on the periphery of the sealant 12 to bond the packaging cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com