Small-volume pefloxacin mesylate freeze-dried powder injection, preparation method and producing device thereof

The technology of pefloxacin mesylate and freeze-dried powder injection is applied in the field of small-volume pefloxacin mesylate freeze-dried powder injection and its preparation, and can solve the problems of increasing filling volume, easy oxidation of products, adding Large water volume and other problems, to achieve the effect of reducing packaging volume, improving product quality and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

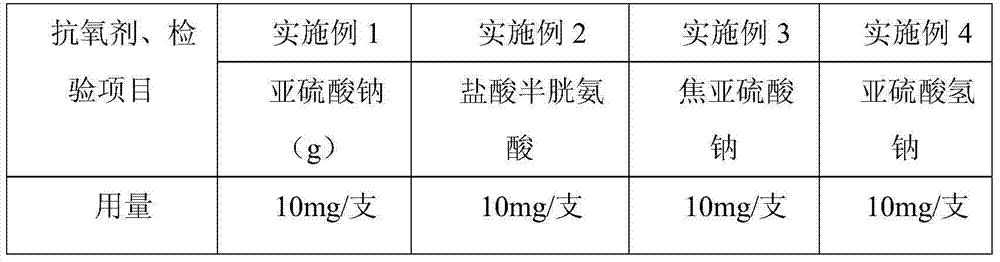

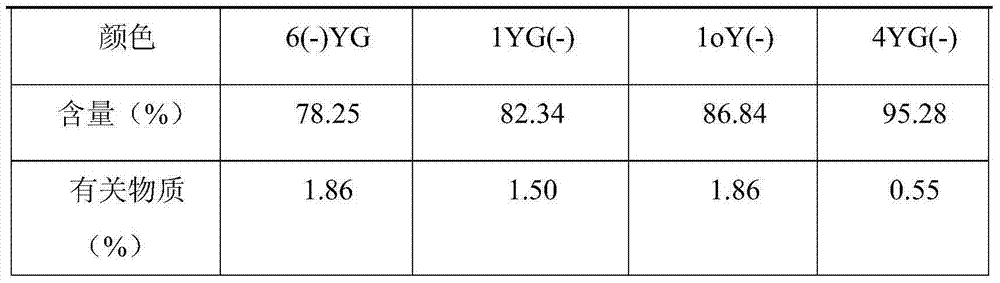

Embodiment 1

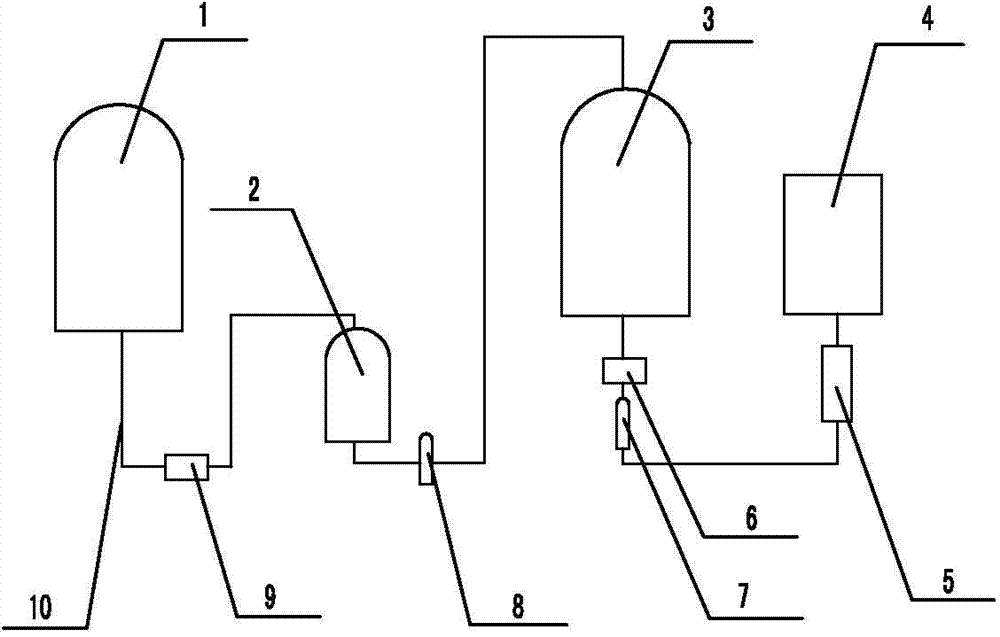

[0024] Add water for injection, pefloxacin mesylate, mannitol and antioxidant, start stirring and dissolving, control the temperature at 20°C to 25°C, control Ph at 3.5, fully stir and dissolve evenly, and make a concentrated solution; add total Decarburization with 0.1% activated carbon for 30 minutes. Turn on the second Grundfos pump 9 and use the titanium rod filter 2 to decarburize and filter the feed liquid through the second sterilizing filter element 8 to sterilize and transport it to the sterile liquid storage tank 3 for storage. After sterilizing and filtering, keep warm at 20°C, turn on the feed liquid circulation pump of the aseptic liquid storage tank 3, the feed liquid passes through the first Grundfos pump 6, the first sterilizing filter element 7, and is filled by the filling machine 5 at a rate of 2ml / The bottle is filled in a 7ml control vial, then freeze-dried by a freeze dryer, corked, capped, and packaged.

[0025] For lyophilization, the temperature of t...

Embodiment 2

[0028] The preparation method of this example is the same as that of Example 1, except that cysteine hydrochloride is used as the antioxidant.

Embodiment 3

[0030] The preparation method of this example is the same as that of Example 1, except that sodium pyrosulfite is used as the antioxidant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com