Ozone catalytic oxidation pretreatment device and method for oil refinery sewage

A technology of ozone catalytic oxidation and pretreatment device, applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage treatment equipment, etc., can solve the problem of low ozone utilization rate, achieve easy control and improve ozone utilization rate , the effect of reducing pollutant load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

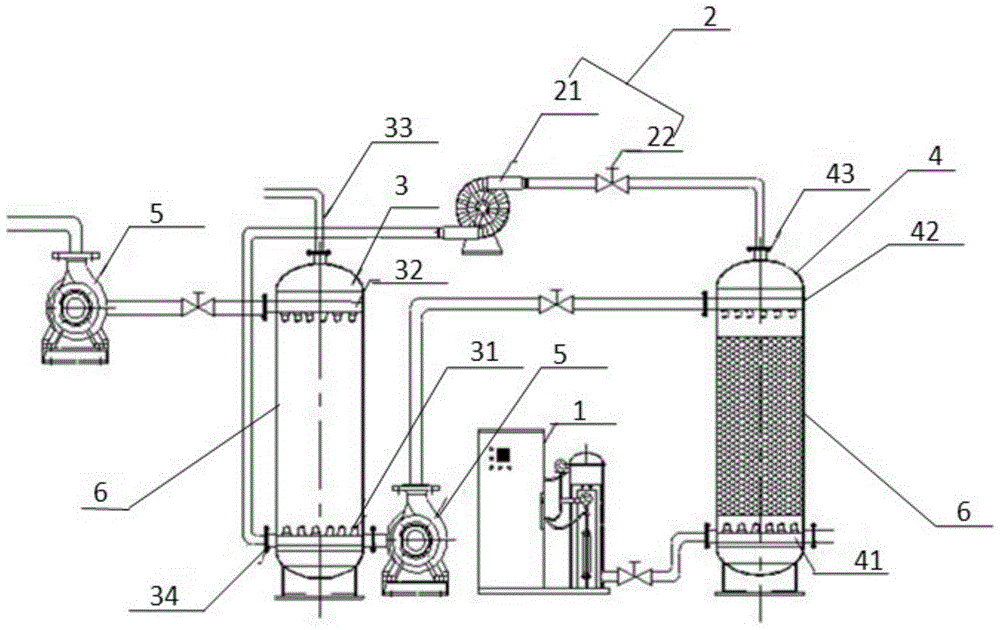

[0046] as attached figure 1 As shown, the embodiment of the present invention provides an ozone catalytic oxidation pretreatment device for oil refining sewage, including an ozone generation system 1, an ozone catalytic oxidation tower 4, an ozone tail gas reuse system 2, and an ozone preoxidation tower 3 arranged in sequence.

[0047]The ozone catalytic oxidation pretreatment device for oil refining sewage provided by the embodiment of the present invention adopts the ozone generation system 1, the ozone catalytic oxidation tower 4, the ozone tail gas reuse system 2 and the ozone preoxidation tower 3 which are connected in sequence, and adopts the ozone tail gas preoxidation- The high-concentration ozone catalytic oxidation process first uses the ozone tail gas to remove the undissolved pollutants in the sewage in the ozone pre-oxidation tower 3, and degrades small molecular organic pollutants to initially reduce the pollutant load, and then in the ozone catalytic oxidation to...

Embodiment 2

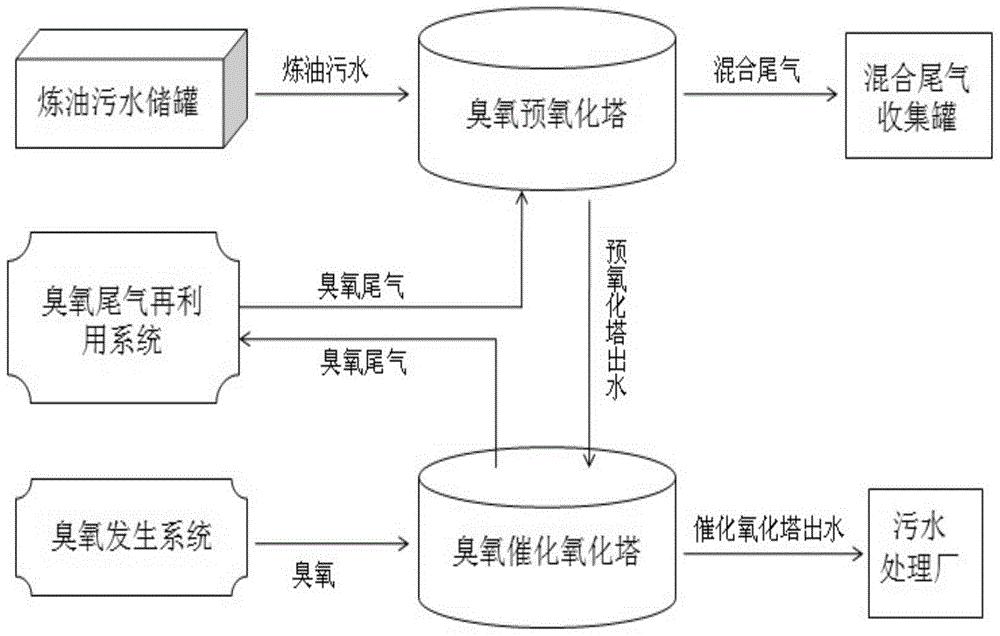

[0059] as attached figure 2 As shown, the embodiment of the present invention provides an ozone catalytic oxidation pretreatment method, comprising the following steps:

[0060] The oil refining sewage is pumped into the ozone pre-oxidation tower and the ozone catalytic oxidation tower in sequence, and at the same time, the ozone generation system is used to provide high concentration and excess ozone to the ozone catalytic oxidation tower, and in the ozone catalytic oxidation tower, the excess ozone is used. The synergistic effect of ozone and solid-phase catalyst degrades the high-concentration macromolecular organic pollutants in the oil refining sewage;

[0061] The oil refining sewage discharged from the ozone catalytic oxidation tower is discharged to the sewage treatment plant for up-to-standard treatment;

[0062] The ozone tail gas in the ozone catalytic oxidation tower is recovered by the ozone tail gas recycling system and supplied to the ozone pre-oxidation tower...

Embodiment 3

[0071] An embodiment of the present invention provides a solid-phase catalyst: comprising a carrier γ-Al 2 O 3 And composite active components Ni, Co, Mn oxides;

[0072] Wherein, the loading amount of the composite active components Ni, Co and Mn oxides is the carrier γ-Al 2 O 3 10w%-25w% of the mass.

[0073] The molar ratio of Ni, Co, and Mn in the composite active components Ni, Co, and Mn oxides is 1:1:0.2;

[0074] The solid-phase catalyst has an average particle size of 3mm-4mm, crushing strength of 150N / cm-260N / cm, a pore size distribution range of 10nm-100nm, and a specific surface area of 150m 2 / g-220m 2 / g, the pore volume is 0.6ml / g-1.5ml / g.

[0075] The solid-phase catalyst with the above physical parameters improves the activity of the catalyst on the one hand, and on the other hand, avoids the reduction of the reaction rate and the blockage of the pipeline caused by the loss of the catalyst due to the loss of materials.

[0076] The solid phase catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com