A method for enhancing anaerobic ammonium oxidation in sediments using waste sludge from water purification plants

A technology of anaerobic ammonium oxidation and waste sludge, which is applied in the field of environmental microorganisms to achieve simple operation procedures, improve the habitat of anaerobic ammonium oxidation bacteria, and strengthen the effect of anaerobic ammonium oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

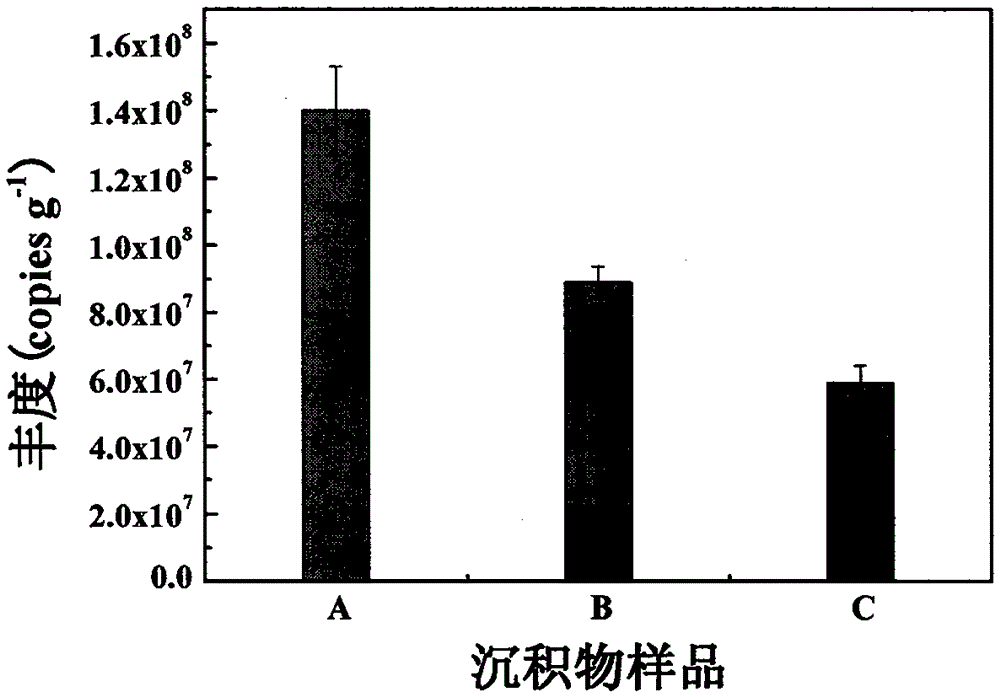

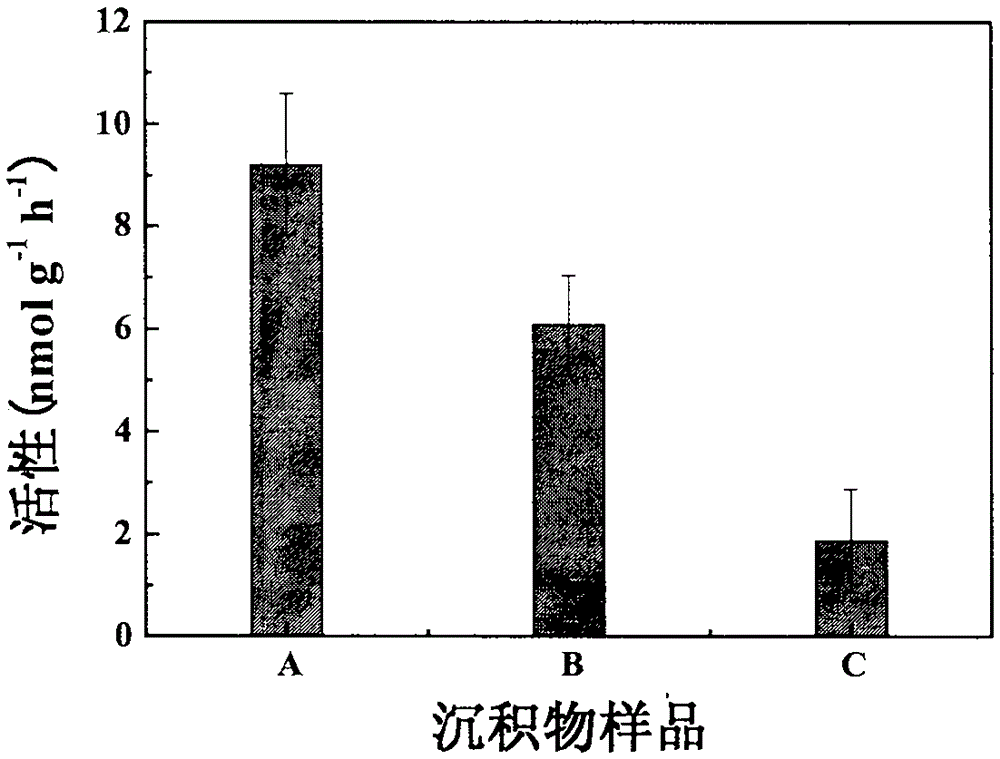

[0023] Example 1: Using waste sludge (WTRs) from a water purification plant in Beijing as raw material, the contents of iron and aluminum in the waste sludge are 150 and 100mg g respectively -1 . After the waste sludge from the water purification plant is dried naturally, it is passed through a 100-mesh sieve. Take 100g of a eutrophic lake sediment in North China, and mix it evenly with 5g of the above-mentioned WTRs. The dosage of the latter is 10% of the dry weight of the former. The bottom and top of the column are cushioned with nylon mesh to prevent the sediment from flowing out. In addition, the second column enriched the sediment without WTRs and used it as a control. Only WTRs were added to the third column for enrichment, and this was used as a blank control. In order to ensure that the system is in an anaerobic state, except for the water inlet and outlet, the entire column is in a sealed state, and the N 2 The deionized water configuration feeds the water. The ...

example 2

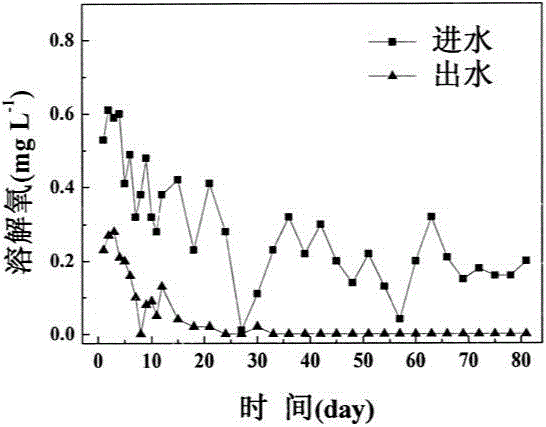

[0026] Example 2: Also use waste mud (WTRs) from a water purification plant in Beijing as raw material, and the waste mud is passed through a 100-mesh sieve after natural drying. Take 80g of a river sediment polluted by high ammonia nitrogen in North China, and mix it evenly with 5g of the above WTRs. The dosage of the latter is 10% of the dry weight of the former. The bottom and top of the column are cushioned with nylon mesh to prevent the sediment from flowing out. In addition, the second column enriched the sediment without WTRs and used it as a control. In order to ensure that the system is in an anaerobic state, except for the water inlet and outlet, the entire column is in a sealed state, and the N 2 The deionized water configuration feeds the water. The water is fed from the bottom up, and the flow rate of the water is 200mL day -1 , a pH of 8, and the initial NH 4 + , NO 2 - and NO3 - Concentrations were 10.0mM, 3.0mM and 5.0mM, NH in water was measured every ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com