Anti-sand screen pipe for deep well

A sandstone and screen pipe technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of shortening the service life of the base pipe, waste of crude oil, economic loss, etc., to prolong the corrosion resistance and reduce the Effect of inspection cycle and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

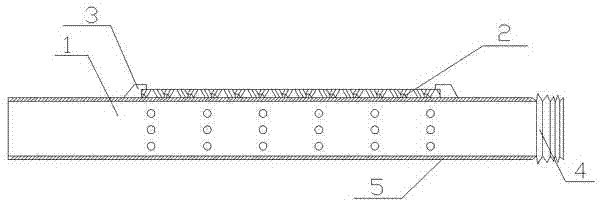

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] A deep well sand prevention screen, comprising a base pipe 1, a screen 2, a stopper 3 and a joint 4, the base pipe 1 is provided with a screen 2, the screen 2 is fixed on the base pipe by welding, and the stopper 3 is set On the outside of the screen 2, the screen 2 is a round-hole stainless steel screen, the base pipe 1 is provided with an anti-corrosion layer 5, and the anti-corrosion layer 5 is an aluminum silicate layer. 4 tail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com