Re-melted and hardened natural gas engine aluminum alloy piston

A technology for engines and natural gas, which is applied in the field of aluminum alloy pistons of natural gas engines, can solve problems such as cracking, and achieve the effects of increased strength, improved service life, and reliable bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

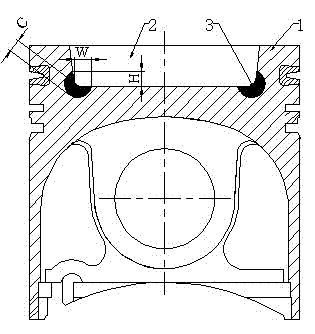

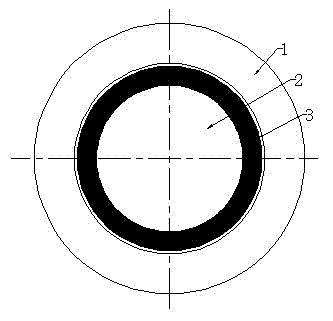

[0012] Such as figure 1 and 2 As shown, a remelted and strengthened natural gas engine aluminum alloy piston includes a piston body and a combustion chamber on the top. An annular remelted strengthening layer is provided at the arc corner of the bottom of the combustion chamber. The cross section of the remelting strengthening layer is an arc shape; the depth C of the remelted strengthening layer, C is 2 ~ 9mm; the radial width W of the remelting strengthening layer, W is 2 ~ 10mm; the axial height H of the remelting strengthening layer, H is 2~10mm.

[0013] A method for remelting and strengthening aluminum alloy pistons of natural gas engines, the specific steps are: (1), pretreatment: cleaning, degreasing and descaling the roughly processed piston blanks, and then heat preservation treatment at 50-150°C 0.5~1.5 hours; ( 2) Remelting treatment: Use tungsten argon arc welding method to remelt the arc corner at the bottom of the piston combustion chamber, fix the welding to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com