High-speed high-temperature hydraulic load-adjustable knife-chip friction device and friction measuring method

A friction device, high temperature technology, applied in the direction of measuring device, measuring heat, using electric device, etc., can solve the problem of lack of high-speed friction experimental device, and achieve the effect of small inertia and sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

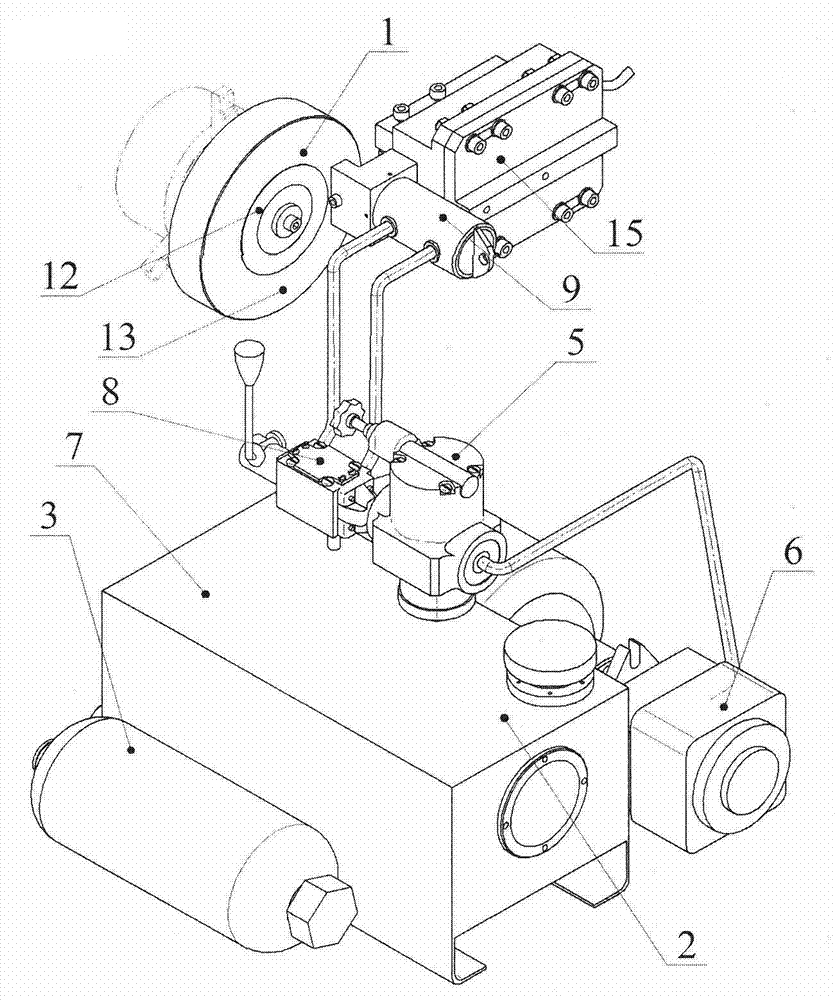

[0036] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0037] as attached figure 1 As shown, the present invention provides a friction device with high-speed, high-temperature hydraulic pressure and adjustable load. Pressure, and by optimizing the hydraulic component 2, the vibration generated during the actual loading process can be effectively reduced to ensure the accuracy and stability of the loading, thereby ensuring the reliability of the friction device. The friction actuator 1 accurately simulates different working conditions of the actual knife-chip friction through the conversion of the tool-chip motion form and the improvement of the tool friction temperature measurement method, and accurately collects axial force, radial force and temperature, etc. data.

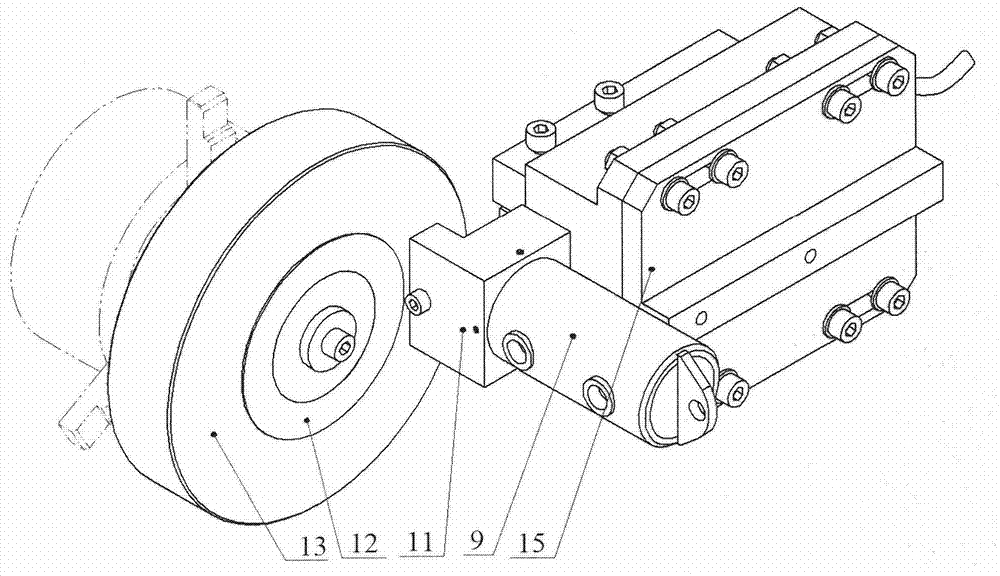

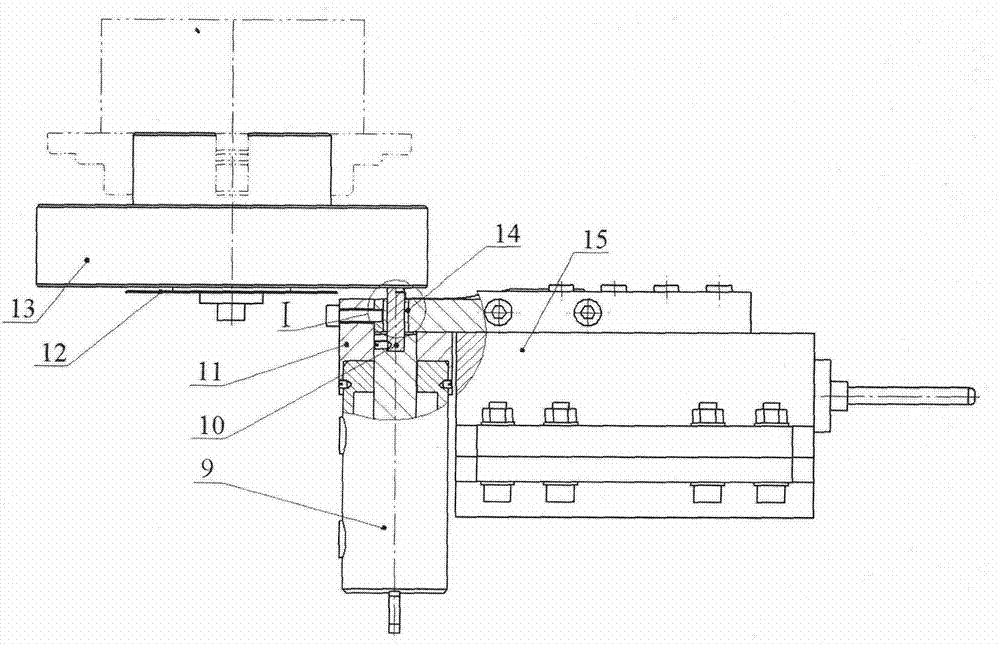

[0038] as attached figure 2 and 3 As shown, the friction actuator assembly 1 includes a hydraulic cylinder 9, an installation ferrule 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com