LDMOS (lateral double-diffused metal oxide semiconductor) transistor structure and formation method thereof

A technology of transistor and gate structure, which is applied in the field of LDMOS transistor structure and its formation, can solve the problem of transistor area increase and achieve the effect of improving breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

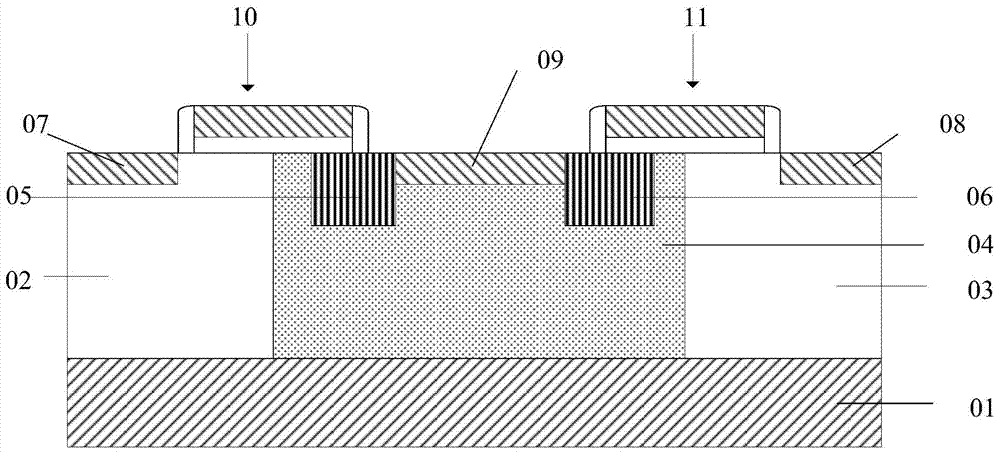

[0070] In the LDMOS transistor structure in the prior art, the size of the STI structure in the horizontal direction is usually increased in the LDMOS transistor, so that the STI structure can share more voltage, thereby increasing the breakdown voltage of the LDMOS transistor. However, while increasing the size of the shallow trench isolation structure in the horizontal direction, the area occupied by the transistor also increases correspondingly.

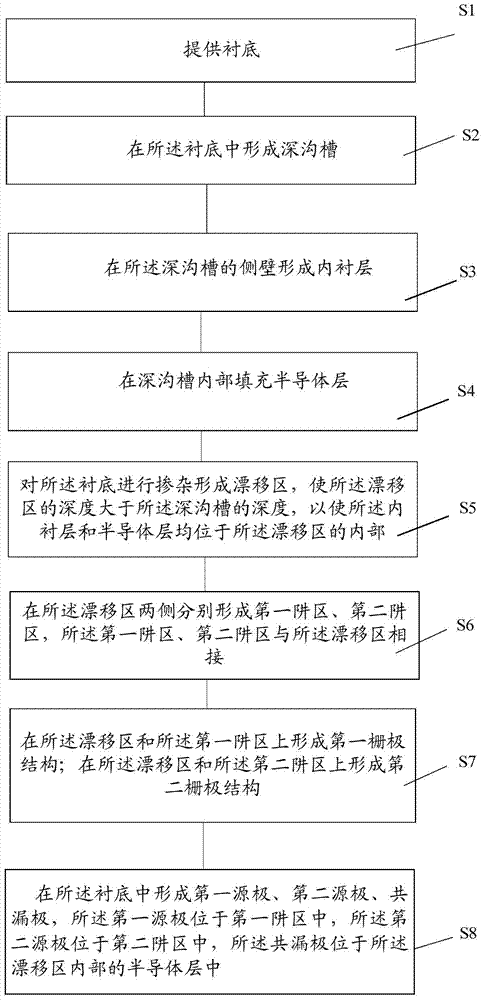

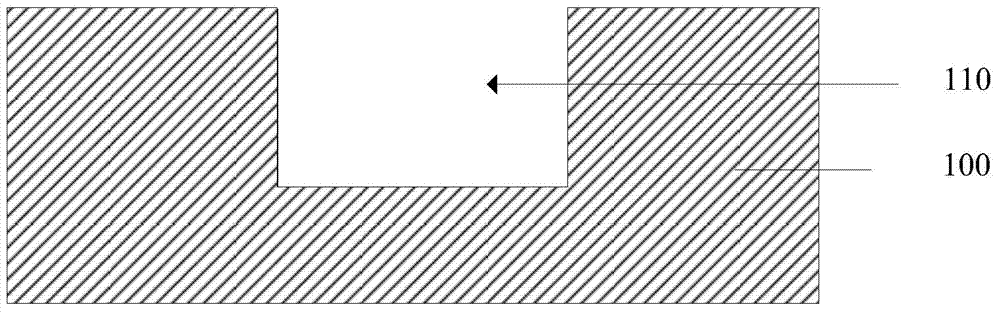

[0071] In order to solve the technical problem, the present invention provides an LDMOS transistor structure and a forming method thereof. The LDMOS transistor structure includes two LDMOS transistors sharing a common drain, the LDMOS transistor structure includes a deep trench, the sidewall of the deep trench is also provided with an inner lining layer, and the common drain is arranged to fill in the In the semiconductor layer of the deep trench, the first source and the second source of the two LDMOS transistors are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com