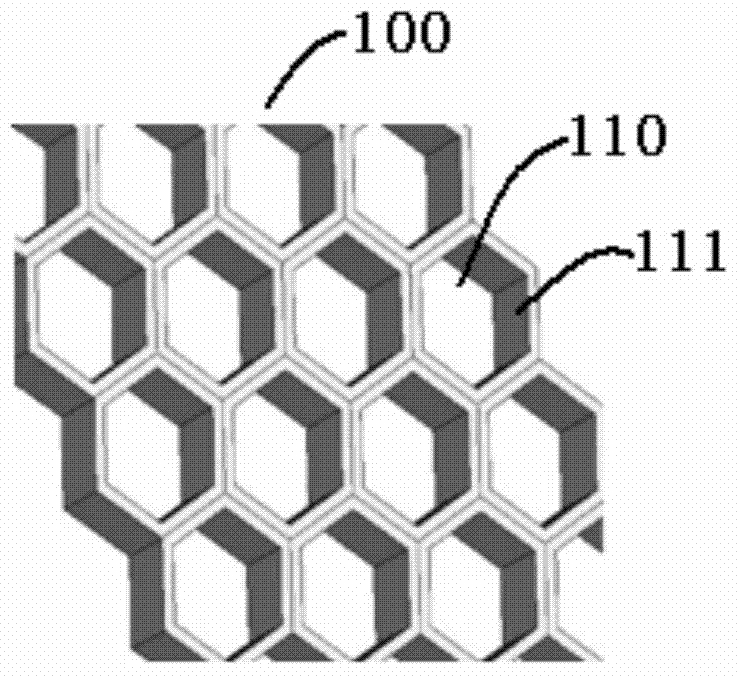

Honeycomb core material, compound wave-absorbing material and honeycomb enhanced metamaterial

A honeycomb core material and metamaterial technology, applied in the direction of electrical components, magnetic field/electric field shielding, etc., can solve the problems of high density, insufficient working frequency band, and insufficient wave absorption effect, and achieve enhanced loss and improved dielectric parameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

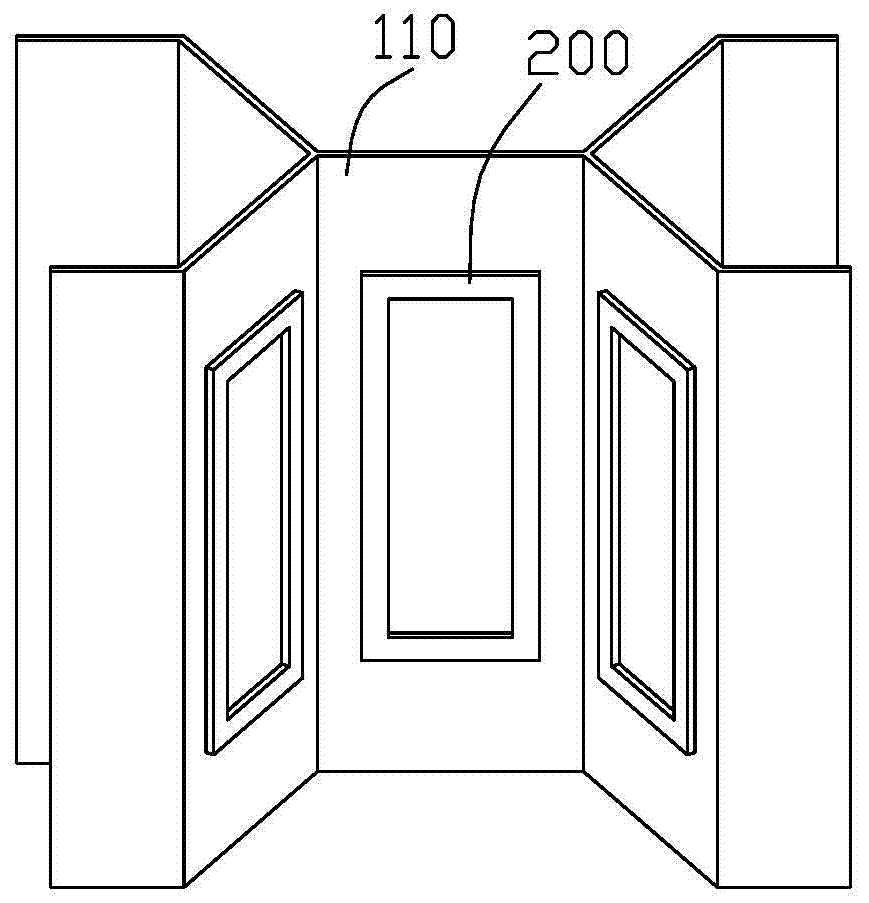

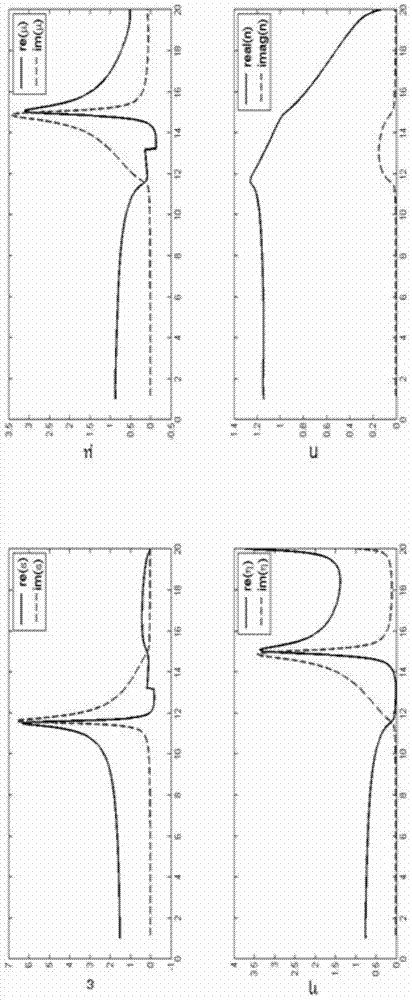

[0025] figure 2 The honeycomb core material shown in this embodiment is a honeycomb core material with a rectangular metal frame-shaped annular microstructure, and its metal material is copper; image 3 As shown, it is the equivalent electromagnetic parameter. Among them, the upper left is the equivalent dielectric constant, the upper right is the equivalent magnetic permeability, the lower left is the impedance of the material, and the lower right is the equivalent refractive index of the material.

Embodiment 2

[0027] The only difference between this embodiment and Embodiment 1 is that the metal microstructure of the honeycomb core material in this embodiment is an annular microstructure, and it can obtain approximately the same technical effect as that of Embodiment 1 through experiments.

Embodiment 3

[0029] The difference between this embodiment and Embodiment 1 is that the metal microstructure of the honeycomb core material in this embodiment is an elliptical ring microstructure, and it can obtain approximately the same technical effect as that of Embodiment 1 through experiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com