Method for cutting sheet metal stock

A technology of thin metal plates and cutting paths, applied in metal processing equipment, welding equipment, laser welding equipment, etc., can solve problems such as complex mobile devices, and achieve the effect of avoiding correction errors and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

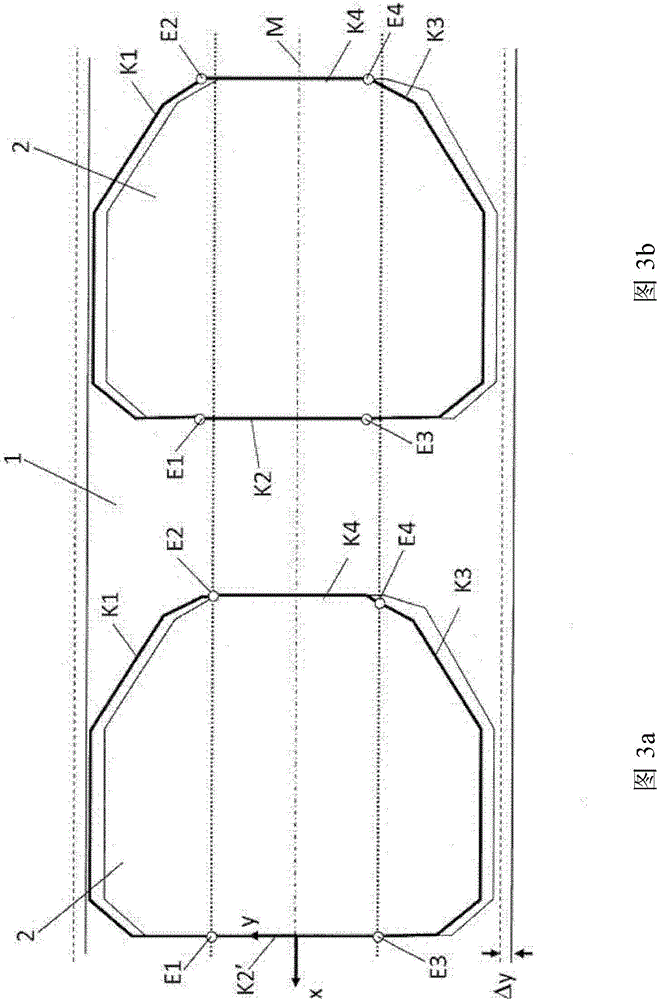

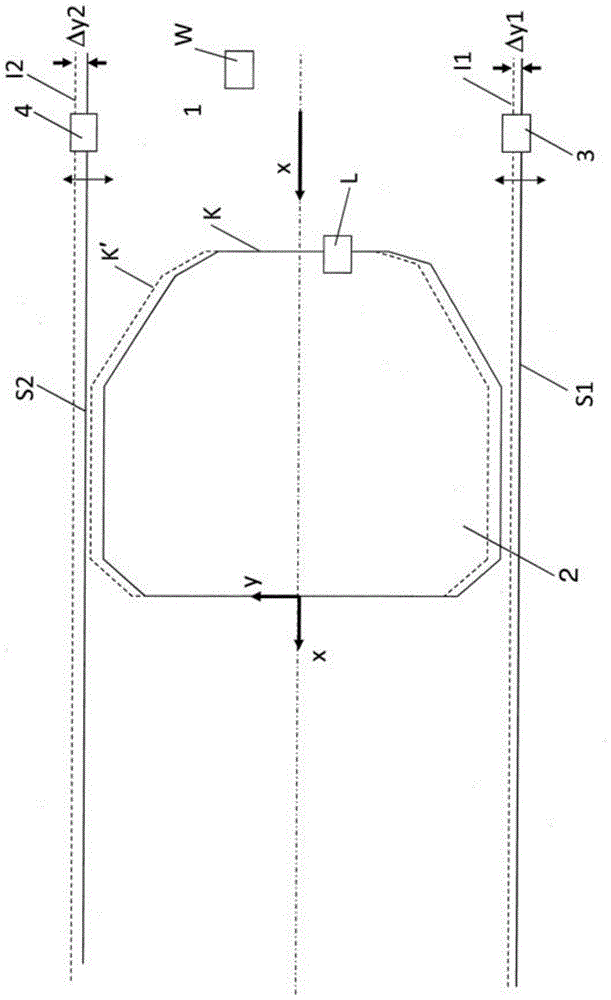

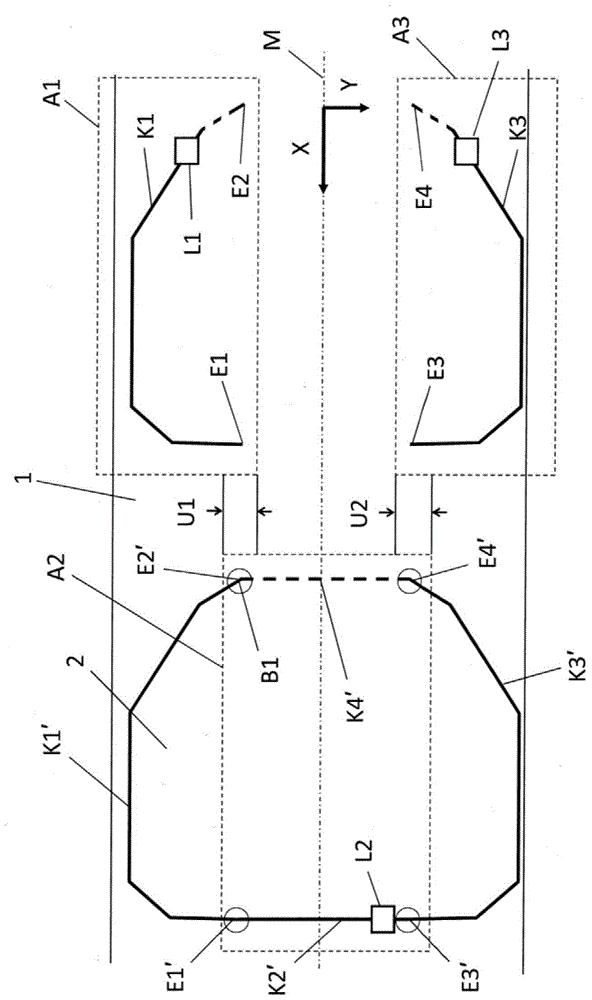

[0069] figure 1 It is a schematic plan view of the sheet metal strip 1 . Reference numeral K designates the outline of the sheet metal blank 2 . Reference sign x denotes the conveying direction of the metal sheet strip 1 . For transport in the transport direction x, the sheet metal strip 1 is moved continuously by means of a transport device (not shown here). For example, the conveying device may be a roller leveler, a conveyor belt or the like.

[0070] The laser cutting device (not shown in more detail here) comprises a laser cutting head L, which is movable both in the conveying direction x and in the direction y perpendicular thereto. In the region of one edge of the sheet metal strip 1, upstream of the laser cutting device, a first distance measuring device 3 is provided, by means of which a first measurement of the edge of the sheet metal from the edge of the sheet metal forming a fixed measuring point is continuously measured The first actual distance I1 of the devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com