Method for obtaining tissue engineering cartilage through directionally inducing bone-marrow mesenchymal stem cells (BMSCs)

A bone marrow mesenchymal and directional induction technology, applied in the field of tissue engineering cartilage obtained by directional induction of bone marrow mesenchymal stem cells, to achieve stable cartilage phenotype, good general shape, and inhibit hypertrophy in vivo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in combination with specific embodiments.

[0036] The method for obtaining tissue-engineered cartilage by directional induction of bone marrow mesenchymal stem cells involved in the present invention is realized by the following steps:

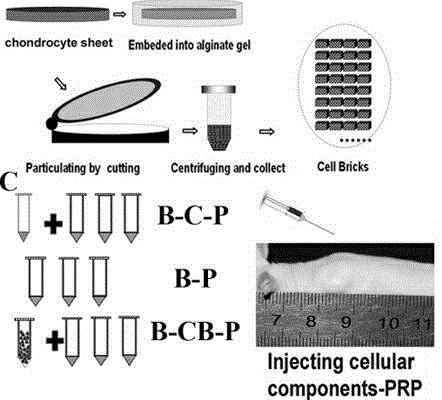

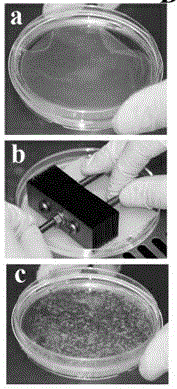

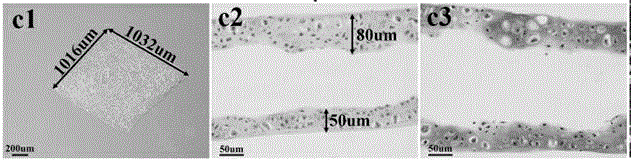

[0037] Step 1: Preparation of large aggregates of chondrocytes and extracellular matrix (cell bricks):

[0038] (1) Isolation of chondrocytes, membrane-forming culture:

[0039] The ear cartilage of 1-month-old New Zealand white rabbits was cut into small pieces and treated with 0.2% type II collagenase (Gibco, USA) solution at 37 ○ C for 12 hours, after that, take the single cell suspension and centrifuge at 1000rpm for 5min in a 15ml centrifuge tube;

[0040] Discard the supernatant, wash once with PBS, centrifuge at 1000rpm for 5min, resuspend the cells with film-forming inducing solution, and dilute the cells in a 6.5×10 5 cells / cm 2 The concentration was planted in a 6-we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com