Preparation method and application of Co3O4/NiO composite mesoporous nanoparticles

A nanoparticle and mesoporous technology, which is applied in the application field of the Co3O4/NiO composite mesoporous nanoparticle in the catalytic activation of methane, can solve the problem of no research on catalytic performance, and achieve uniform morphology, high dispersion and particle size. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

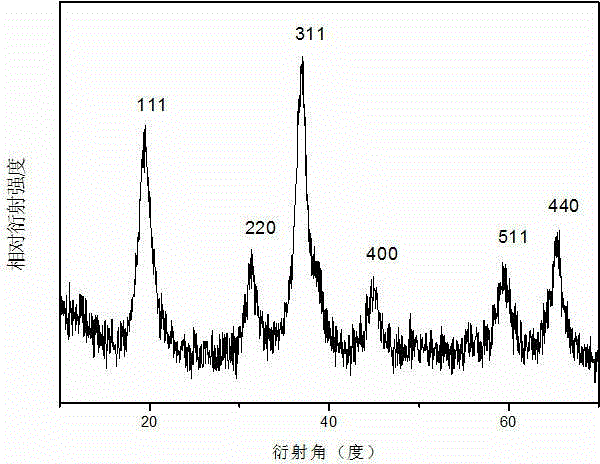

[0023] a)Co 3 o 4 Preparation of nanoparticles

[0024] 30ml0.5mol / L Co(CH 3 COO) 2 The solution was placed in a water bath at 70°C, 20ml of 4mol / L NaOH solution was slowly added thereto, and magnetically stirred for 60min. After the solution was cooled to room temperature, it was filtered and washed to obtain Co(OH) 2 precipitation. After drying, Co(OH) 2 Calcined in a muffle furnace. The calcination temperature is 180°C, and the calcination time is 3h. After calcination, Co 3 o 4 Nanoparticles.

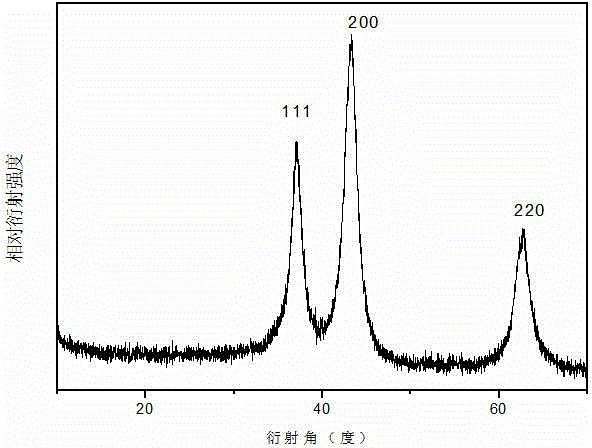

[0025] b)Co 3 o 4 Preparation of / NiO Composite Mesoporous Nanoparticles

[0026] 0.0056g Co 3 o 4 Ultrasonic dispersion in 30ml distilled water, adding 3.49gNi(NO 3 ) 2 . 6H 2 O, after stirring evenly, slowly dropwise add 60ml NaOH solution containing 1.80gNaOH. After stirring for 10 minutes, transfer it into a 100ml reaction kettle, keep at 160°C for 15h, wash with distilled water and ethanol respectively, dry at 60°C, and calcinate at 200°C for 4h to obtain Co 3...

Embodiment 2

[0029] a)Co 3 o 4 Preparation of nanoparticles

[0030] 60ml0.2mol / L Co(CH 3 COO) 2 The solution was placed in a water bath at 70°C, 5ml of 1mol / L NaOH solution was slowly added thereto, and magnetically stirred for 120min. After the solution was cooled to room temperature, it was filtered and washed to obtain Co(OH) 2 precipitation. After drying, Co(OH) 2 Calcined in a muffle furnace. The calcination temperature is 300°C, and the calcination time is 1h. After calcination, Co 3 o 4 Nanoparticles.

[0031] b) Co. 3 o 4 Preparation of / NiO Composite Mesoporous Nanoparticles

[0032] 0.0291gCo 3 o 4 Ultrasonic dispersion in 60ml distilled water, adding 1.74gNi(NO 3 ) 2 . 6H 2 O, after stirring evenly, slowly add dropwise the 30mlNaOH solution containing 0.24gNaOH. After stirring for 30 minutes, transfer it into a 100ml reaction kettle, keep at 160°C for 24h, wash with distilled water and ethanol respectively, dry at 60°C, and calcinate at 400°C for 0.5h to obta...

Embodiment 3

[0035] a)Co 3 o 4 Preparation of nanoparticles

[0036] 40ml0.25mol / L Co(CH 3 COO) 2 The solution was placed in a water bath at 70°C, 10ml of 2mol / L NaOH solution was slowly added thereto, and magnetically stirred for 60min. After the solution was cooled to room temperature, it was filtered and washed to obtain Co(OH) 2 precipitation. After drying, Co(OH) 2 Calcined in a muffle furnace. The calcination temperature is 200°C, and the calcination time is 1h. After calcination, Co 3 o 4 Nanoparticles.

[0037] b) Co. 3 o 4 Preparation of / NiO Composite Mesoporous Nanoparticles

[0038] 0.5520g Co 3 o 4 Ultrasonic dispersion in 40ml distilled water, adding 2.00gNi(NO 3 ) 2 . 6H 2 O, after stirring evenly, slowly dropwise add 40ml NaOH solution containing 0.80gNaOH. After stirring for 40min, transfer it into a 100ml reaction kettle, keep at 180°C for 15h, wash with distilled water and ethanol respectively, dry at 60°C, and calcinate at 250°C for 1h to obtain Co 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com