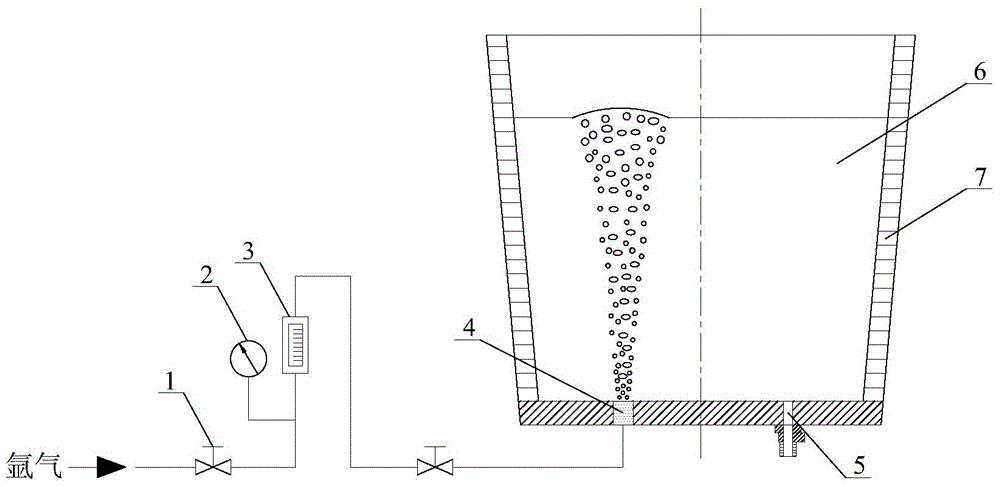

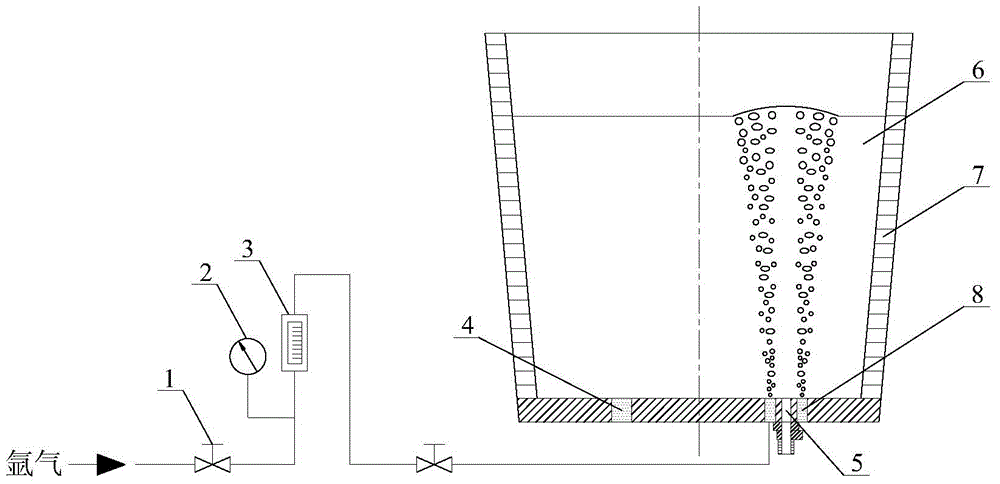

Method for controlling steel ladle tapping slag by blowing argon gas to annular steel outlet in bottom of steel ladle

A technology of tapping hole and bottom ring, which is applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems of floating valve consumables, high price, and difficulty in adding drainage sand, so as to prevent slag from entering the tundish , the effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The ladle that adopts in the present embodiment is 50 tons.

[0020] During the pouring process of the ladle, when the liquid level of the molten steel in the ladle is 150mm, the argon blowing pressure is controlled to be 0.2MPa, and the argon blowing flow rate is 1Nm 3 / h, so that argon gas is blown into the molten steel through the ring-shaped breathable brick. The breathable width of the ring-shaped breathable brick is 50mm, which can suppress the slag from the ladle and increase the yield of molten steel in the ladle pouring process.

[0021] Using the above process parameters, compared with the traditional ladle leaving steel operation to control the slag lowering process, the molten steel yield in the ladle pouring process is increased by 14%.

Embodiment 2

[0023] The ladle that present embodiment adopts is 80 tons.

[0024] During the pouring process of the ladle, when the liquid level of the molten steel in the ladle is 220mm, the argon blowing pressure is controlled to be 0.4MPa, and the argon blowing flow rate is 11Nm 3 / h, so that argon gas is blown into the molten steel through the annular air-permeable brick. The air-permeable width of the annular air-permeable brick is 150mm, which can suppress the slag from the ladle and increase the yield of molten steel during the ladle pouring process.

[0025] Using the above process parameters, compared with the traditional ladle leaving steel operation to control the slag lowering process, the molten steel yield in the ladle pouring process is increased by 15%.

Embodiment 3

[0027] The ladle that present embodiment adopts is 180 tons.

[0028] During the pouring process of the ladle, when the liquid level of the molten steel in the ladle is 400mm, the argon blowing pressure is controlled at 0.7MPa, and the argon blowing flow rate is 20Nm 3 / h, so that argon gas is blown into the molten steel through the annular air-permeable brick. The air-permeable width of the annular air-permeable brick is 300mm, which can suppress the slag of the ladle and increase the yield of molten steel during the ladle pouring process.

[0029] Using the above process parameters, compared with the traditional ladle leaving steel operation to control the slag lowering process, the molten steel yield in the ladle pouring process is increased by 17%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com