Internal protection device for stainless steel pipe repair

A stainless steel tube and protection device technology, applied in auxiliary devices, tubular articles, applications, etc., can solve the problems of difficulty in determining the specific location of defects in the tube, inability to locate air grooves, and high production costs, saving air consumption, facilitating repair work, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

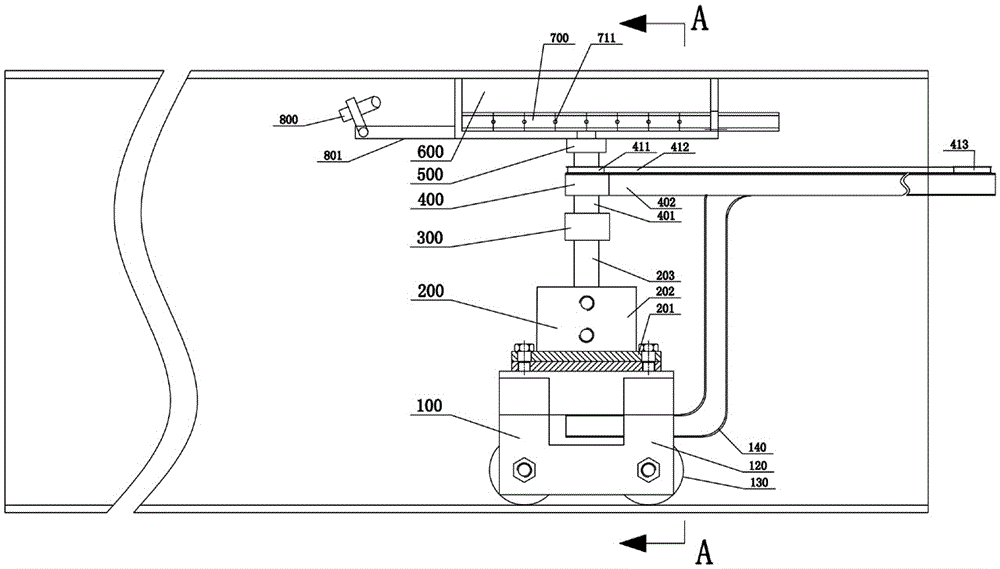

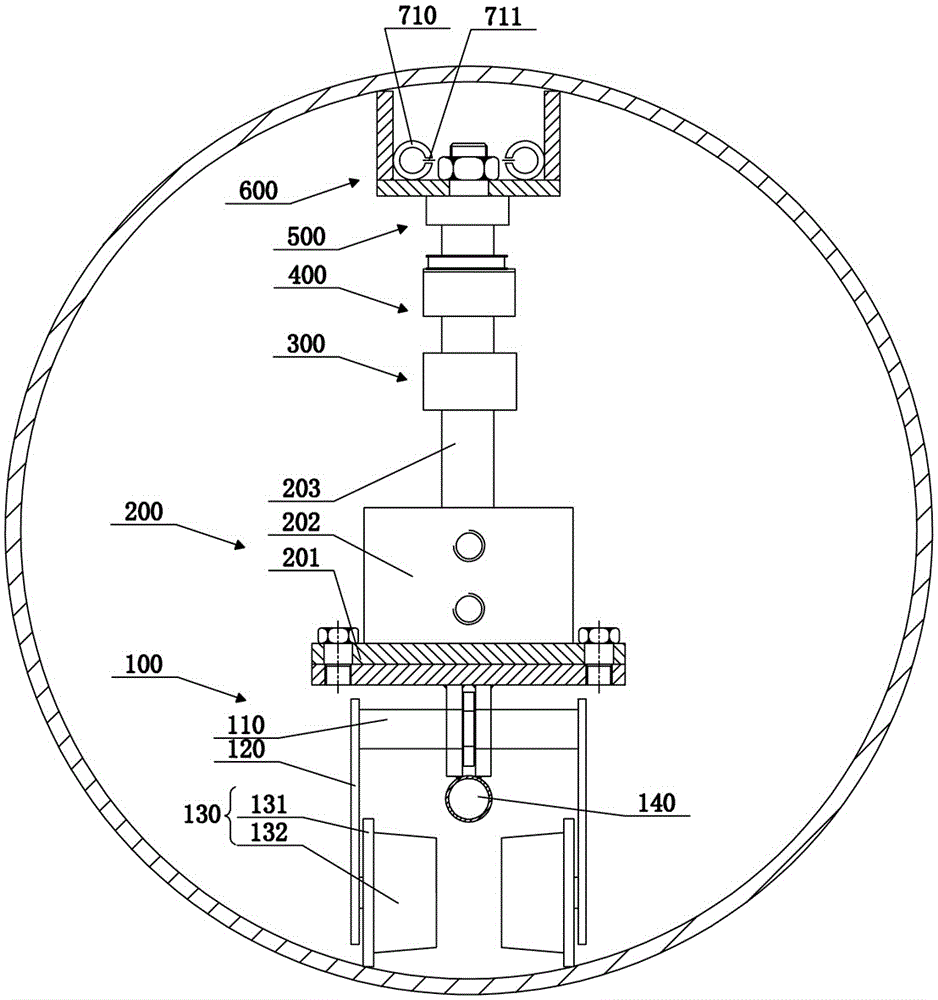

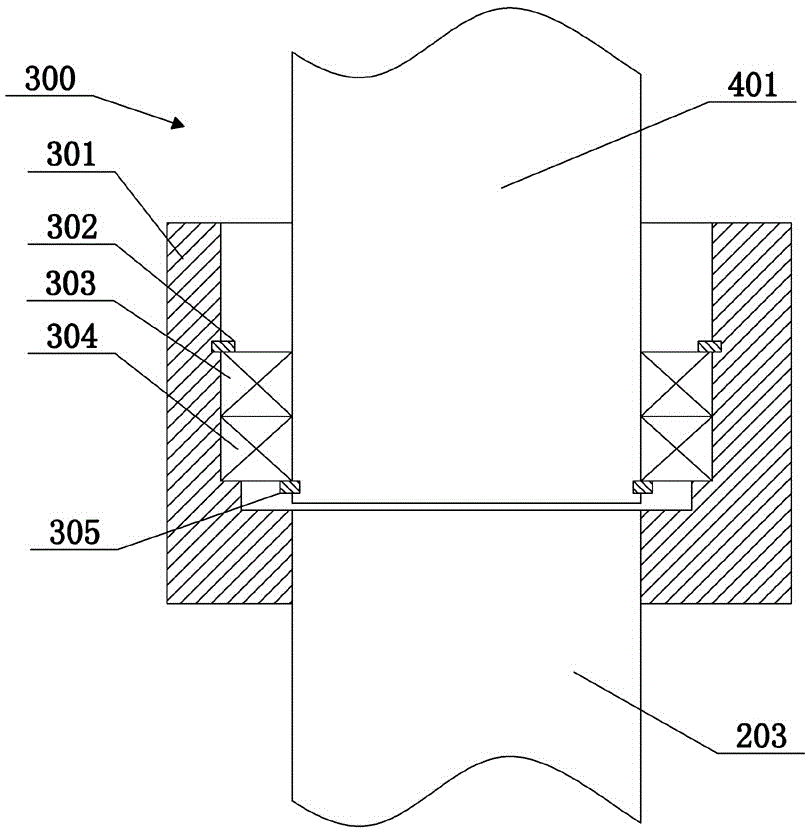

[0031] The internal protection device for stainless steel pipe rework includes a mobile trolley 100, a height adjustment device 200, a rotation adjustment device 400, an angle adjustment device 500, a push rod 140, an air groove 600, an air pipe 700 and an endoscope 800.

[0032] The height adjusting device 200 is arranged above the moving trolley 100 . The rotation adjustment device 400 is disposed above the height adjustment device 200 . The angle adjustment device 500 is disposed above the rotation adjustment device 400 . The air groove 600 is disposed above the angle adjusting device 500 .

[0033] The moving trolley 100 includes a top board 110 , side boards 120 and wheels 130 . The side panels 120 are symmetrically arranged on both sides of the top panel 110 . The wheels 130 are rotatably connected to the inside of the side plate 120 . Preferably, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com