Hot belt forming composite aluminum hard sheet

A technology of compounding aluminum and hard sheets, applied in the field of pharmaceutical packaging materials, can solve the problems of large loss of rolling equipment, affecting normal use, increasing production costs, etc., to improve rolling stability, improve warpage, and improve impact strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

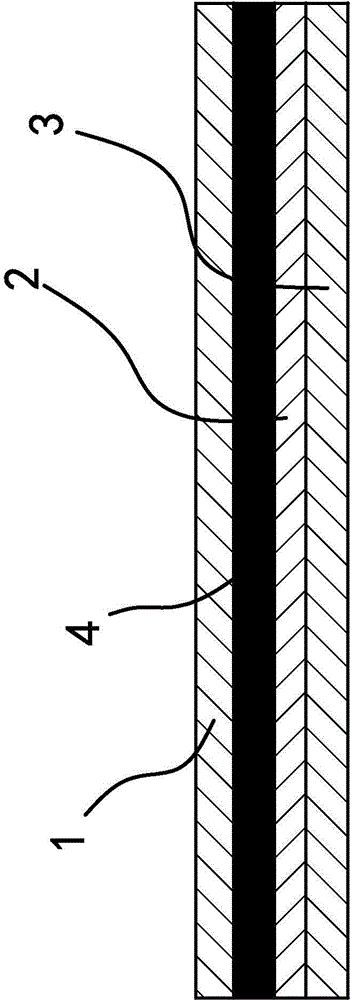

[0048] A composite aluminum hard sheet formed by hot strips includes a PET layer 1, an aluminum foil layer 2 and a heat-sealing adhesive layer 3 arranged in sequence, and a glue layer 4 is arranged between the PET layer and the aluminum foil layer, and the glue layer is glued The density is 4.9g / cm 3 , the thickness of the PET layer is 30 μm, the thickness of the aluminum foil layer is 60 μm, and the total thickness of the hot-band forming composite aluminum hard sheet is 97.5 μm.

[0049] Wherein, the PET alloy material of the PET layer is made by the following method:

[0050] Dry PET at 140°C for 3.5 hours, PBT at 135°C for 4 hours, and flame retardant at 83°C for 35 minutes, ready to use;

[0051] Weigh the dried PBT and PET according to the weight ratio, and after mixing evenly, add the plasticizer, lubricant, antioxidant and stabilizer according to the weight ratio, and then add them into the high-speed mixer to fully Mix for 15 minutes; the weight ratio is: PBT: 20%, ...

Embodiment 2

[0059] A composite aluminum hard sheet formed by hot strips includes a PET layer 1, an aluminum foil layer 2 and a heat-sealing adhesive layer 3 arranged in sequence, and a glue layer 4 is arranged between the PET layer and the aluminum foil layer, and the glue layer is glued The density is 5.0g / cm 3 , the thickness of the PET layer is 25 μm, the thickness of the aluminum foil layer is 65 μm, and the total thickness of the hot-band forming composite aluminum hard sheet is 97 μm.

[0060] Wherein, the PET alloy material of the PET layer is made by the following method:

[0061] Dry PET at 130°C for 4 hours, PBT at 130°C for 5 hours, and flame retardant at 80°C for 45 minutes before use;

[0062] Weigh the dried PBT and PET according to the weight ratio, and after mixing evenly, add the plasticizer, lubricant, antioxidant and stabilizer according to the weight ratio, and then add them into the high-speed mixer to fully Mix for 20 minutes; the weight ratio is: PBT: 30%, PET: 50...

Embodiment 3

[0070] A composite aluminum hard sheet formed by hot strips includes a PET layer 1, an aluminum foil layer 2 and a heat-sealing adhesive layer 3 arranged in sequence, and a glue layer 4 is arranged between the PET layer and the aluminum foil layer, and the glue layer is glued The density is 4.8g / cm 3 , the thickness of the PET layer is 35 μm, the thickness of the aluminum foil layer is 55 μm, and the total thickness of the hot-band forming composite aluminum hard sheet is 98 μm.

[0071] Wherein, the PET alloy material of the PET layer is made by the following method:

[0072] Dry PET at 150°C for 3 hours, PBT at 140°C for 3 hours, and flame retardant at 85°C for 30 minutes, ready to use;

[0073] Weigh the dried PBT and PET according to the weight ratio, and after mixing evenly, add the plasticizer, lubricant, antioxidant and stabilizer according to the weight ratio, and then add them into the high-speed mixer to fully Mix for 10 minutes; the weight ratio is: PBT: 15%, PET:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com