Treatment process for domestic sewage

A technology for treating process and domestic sewage, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Liquid separation and other problems, to achieve the effect of improving the removal rate of SS, reducing the production of sludge, and reducing the cost of sludge treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] After the sewage is pretreated, it is treated in turn in the primary sedimentation tank, biological tank and secondary sedimentation tank. The biological tank includes anoxic section, anaerobic section, second anoxic section, second anaerobic section, third anoxic section Oxygen section, aerobic section;

[0021] The sewage and the return sludge from the secondary sedimentation tank are mixed and then enter the anoxic section (DO 0.2-0.5mg / L) for treatment, and the sewage residence time is 0.3h;

[0022] The effluent from the anoxic section enters the anaerobic section (DO≤0.2mg / L) for treatment, and the sewage residence time is 0.2h;

[0023] The effluent from the anaerobic section is mixed with the return sewage from the aerobic section and enters the second anoxic section (DO 0.2-0.5mg / L) for treatment. The sewage return rate is 20-50%, and the sewage residence time is 0.4h;

[0024] The effluent from the anoxic section enters the second anaerobic section (DO≤0.2mg / ...

experiment example

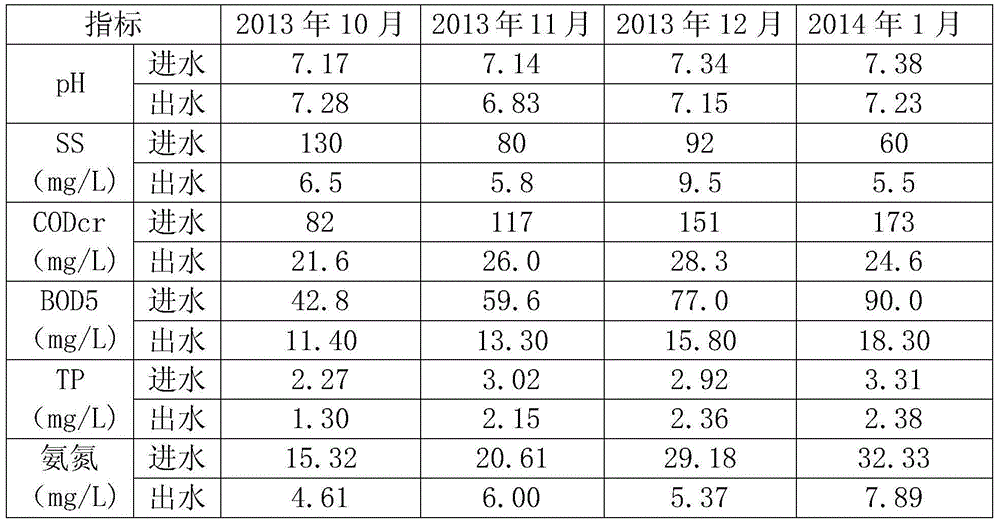

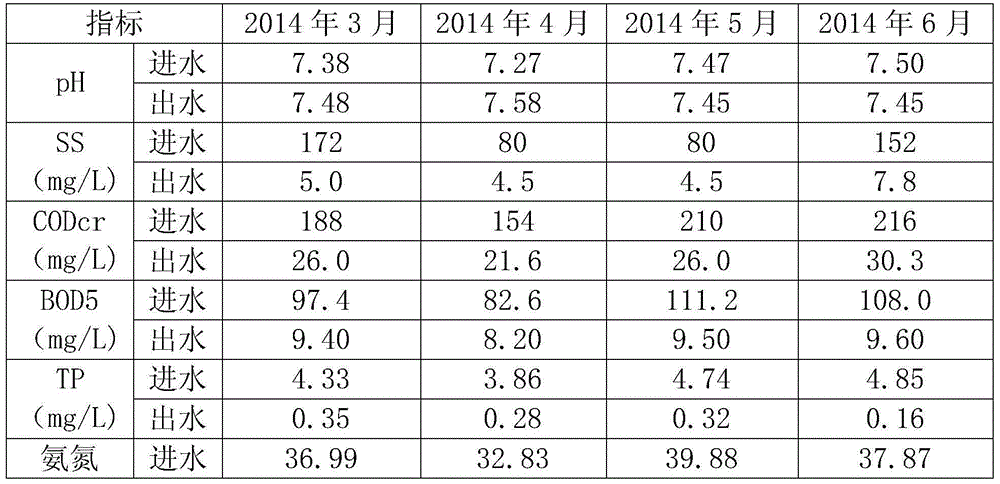

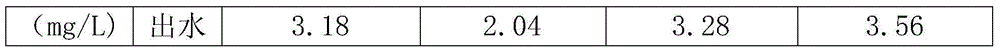

[0028] Taking an urban sewage treatment plant as an example, A / O treatment process is adopted. Table 1 shows the actual operation data of the plant for four consecutive months from October 2013 to January 2014. "(GB18918-2002) secondary standard. The plant began to adopt the treatment process of the present invention from March to June, 2014, and detected that the effluent of these four months fully reached the first-class A standard in the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002). For details, see Table 2.

[0029] Table 1

[0030]

[0031] Table 2

[0032]

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com