A low-temperature anaerobic treatment device for industrial wastewater and its treatment process

An anaerobic treatment device and treatment process technology, which is applied in textile industrial wastewater treatment, anaerobic digestion treatment, aerobic and anaerobic process treatment, etc., can solve the problems affecting microbial degradation, lack of system dynamics and thermodynamics, It does not consider the problem of high-efficiency reflux of the microbial temperature system, and achieves good film-hanging effects, reduced management and operating costs, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

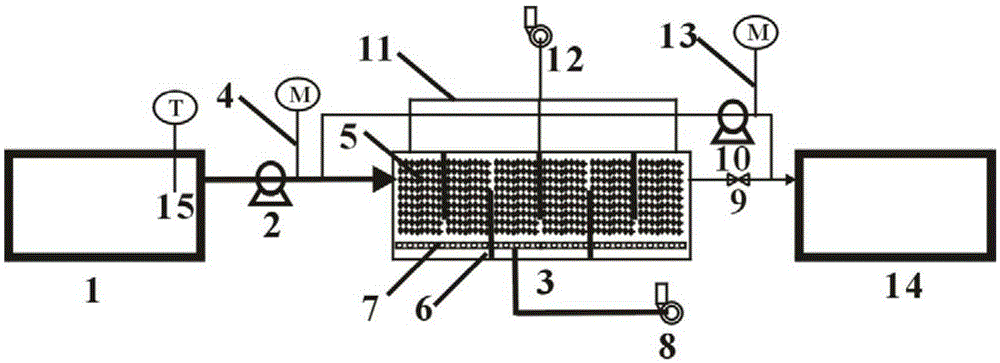

Image

Examples

Embodiment 1

[0050] A chemical company limited company uses alkyl glycoside (APG) series nonionic surfactants, alcohol ether carboxylate (AEC) series anionic surfactants, imidazoline series amphoteric surfactants and other new green products with market prospects, The production of surfactant wastewater is 100 tons / day, the influent COD concentration is 3000-6000mg / L, the effluent COD removal rate is as high as 80% through the low-temperature anaerobic hydrolysis unit (residence time 36h), and the anaerobic system load can reach 4kgCOD / (m3d). In the extreme influent concentration COD=20000mg / L, the effluent COD is less than 6000mg / L, and the removal rate is higher than 70%, which reflects the high treatment efficiency. The overall system temperature is not heated throughout the year. When the temperature is 30 degrees Celsius, the removal rate is higher than 80%; when the temperature is 15-20 degrees Celsius, the removal rate is still higher than 70%.

Embodiment 2

[0052] A US-funded Electric Co., Ltd. adopts this low-temperature anaerobic hydrolysis unit for comprehensive emulsion and release agent wastewater. When the influent concentration is 3000-4000 mg / L and the influent temperature changes from 15 to 25 degrees Celsius, the removal rate of the anaerobic unit Above 75%, BOD / COD increased from 0.2 to 0.35.

Embodiment 3

[0054] A textile printing and dyeing enterprise produces a large amount of printing and dyeing wastewater. The volume of wastewater is 200 tons per day. The low-temperature anaerobic hydrolysis unit is used. When the influent concentration is 1500-2000mg / L and the chroma is 400-600 times, the anaerobic load adopts When the temperature is 3kgCOD / (m3d), when the temperature is 15-32 degrees Celsius for 365 days a year, the COD removal rate of the effluent is 30%, the chroma removal rate is as high as 90%, and the BOD / COD is increased from 0.18 to 0.4 or more

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com