Undone nitrogen doped carbon nanotubes derivative with good electrochemical performance

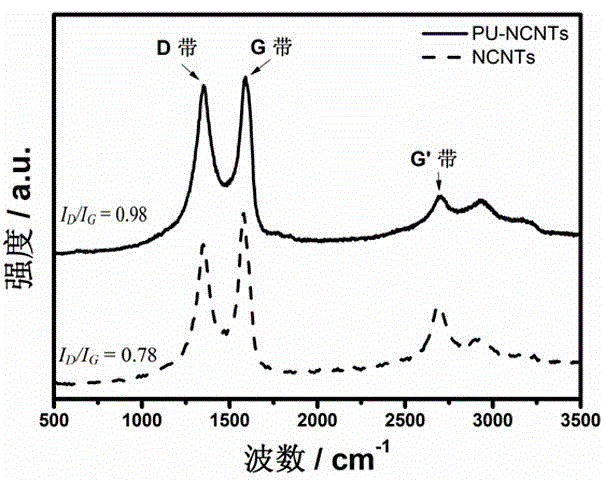

A technology of nitrogen-doped carbon and multi-walled carbon nanotubes, which is applied in the field of electrochemistry, can solve the problems of surface area active state limitation and unfavorable applications in the field of electrochemistry, and achieve good conductivity, large specific surface area, and multiple reactive active points. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

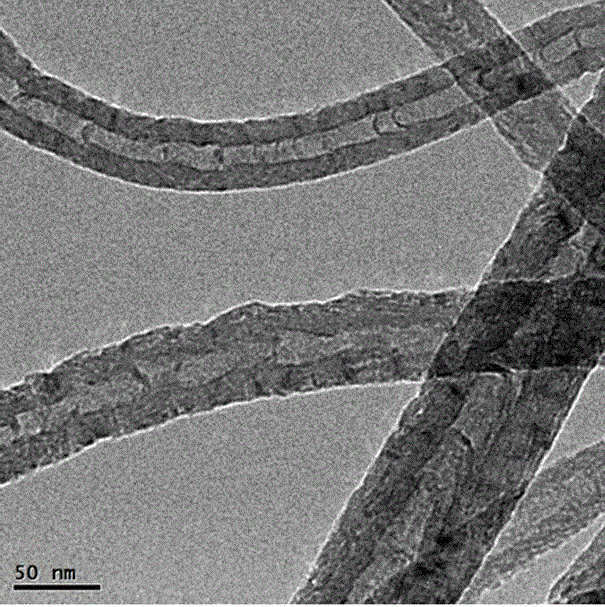

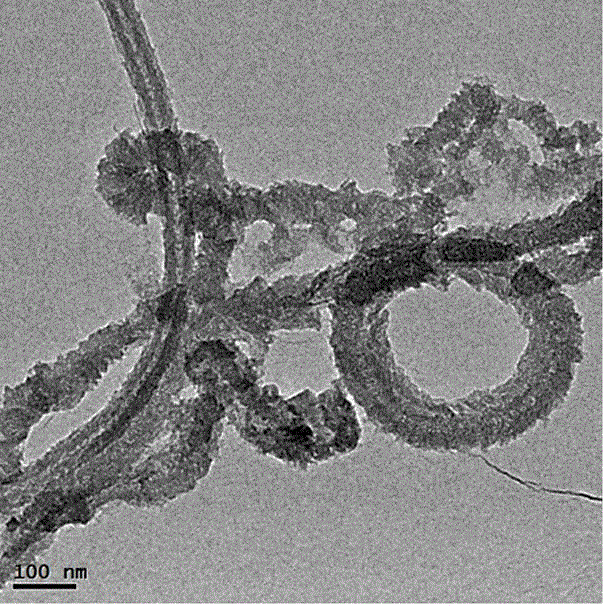

[0039] Dissolve 150 mg of nitrogen-doped multi-walled carbon nanotubes (NCNTs) in 36 mL of H 2 SO 4 , stirred moderately for 1 h until the mixture was homogeneous. Then, add 4 mL of 85% H 3 PO 4 And continue to stir for 15 min, slowly add 450 mg of KMnO 4 (It takes about half an hour to add). The mixture was heated to 65°C and kept stirring slowly for 2 h to avoid cutting the oxidized carbon tubes into pieces. After stirring, the mixture was taken out and allowed to stand at room temperature. Add 100 mL of ice water (including 5 mL of 30% hydrogen peroxide) to the mixture, and let it stand for 14 hours to separate the layers. Subsequently, the upper layer solution was poured out, and the solution was filtered with a 0.22 μm microporous aqueous acid-base-resistant (PTFE) filter membrane, and washed twice with 6 mL of 20% HCl during suction filtration. Afterwards, take the filter residue and dissolve it in 60 mL of water. After ultrasonication for 2 minutes, stir slowly u...

Embodiment 2

[0043] Dissolve 150 mg of NCNTs in 36 mL H 2 SO 4 , stirred moderately for 1 h until the mixture was homogeneous. Then, add 7.2 mL of 85% H 3 PO 4 And continue to stir for 15 min, after the mixture is heated to 80 °C, slowly add 750 mg of KMnO 4 , at this time, keep stirring slowly for 2 h to avoid cutting the oxidized carbon tubes into pieces. After stirring, the mixture was taken out and allowed to stand at room temperature. Then, 100 mL of ice water (containing 5 mL of 30% hydrogen peroxide) was added to the mixture, and the solution was allowed to stand to separate layers. Subsequently, the upper layer solution was poured out, and the solution was filtered with a 0.22 μm microporous PTFE filter membrane, and washed twice with 6 mL of 20% HCl during suction filtration. Thereafter, the filter residue was dissolved in 60 mL of water and dispersed evenly with the aid of ultrasound, and then 40 mL of 30% HCl was added to the dispersion. Filtrate with the same PTFE filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com