Porous polyvinylidene fluoride-carbon nanotube composite material and preparation method thereof

A polyvinylidene fluoride and carbon nanotube technology, which is applied in the field of porous polyvinylidene fluoride-carbon nanotube composite materials and their preparation, can solve the problems of limiting the wide application of thermoelectric fields, high price, environmental pollution, etc., and achieves reduction of thermal conductivity. coefficient, high Seebeck coefficient, effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

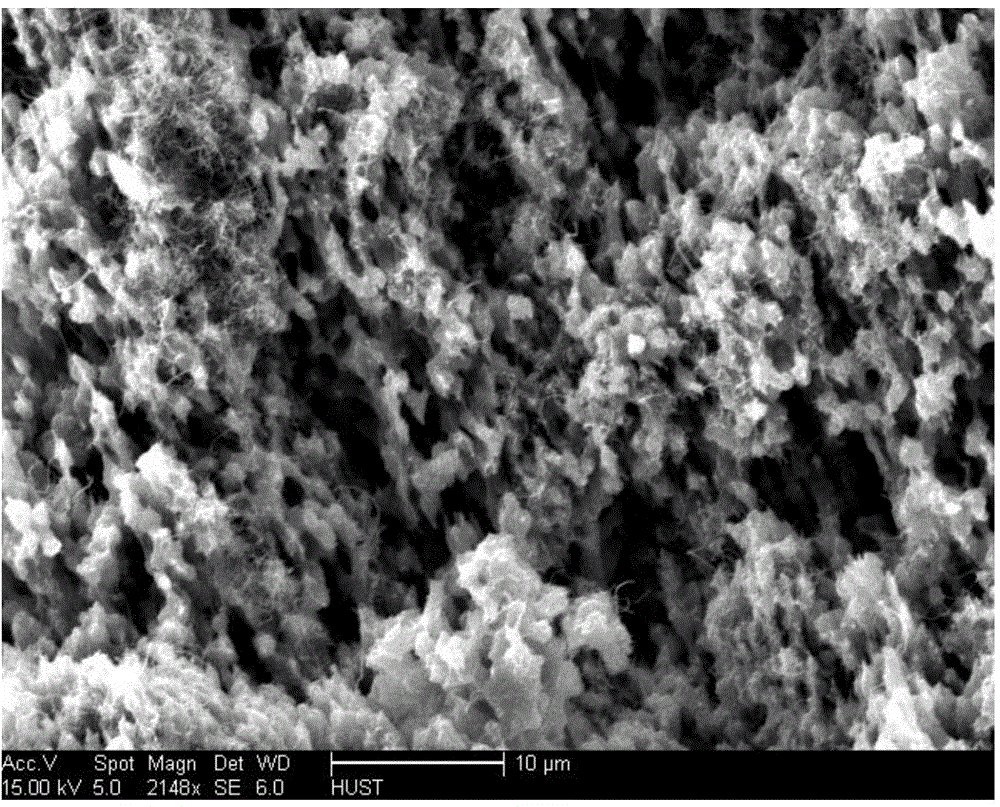

Image

Examples

Embodiment 1

[0025] A porous polyvinylidene fluoride-carbon nanotube composite material is prepared by the following steps:

[0026] 1) Add 10 g of single-walled carbon nanotubes with a diameter of about 40 to 60 nm and a length of about 5 to 15 μm into a mixed acid of concentrated sulfuric acid (50 ml, a concentration of 98 wt %) and concentrated nitric acid (150 ml, a concentration of 65 wt %), After ultrasonic dispersion for 1 hour, the temperature was raised to 80°C and refluxed at 80°C for 6 hours, then the mixed solution was poured into deionized water for dilution, filtered and dried to obtain black powder, that is, acidified carbon nanotubes.

[0027] 2) Add 1000 mg of the obtained acidified carbon nanotubes and 4 ml of polyethylene glycol-400 into 40 ml of DMF solvent, heat and stir in a water bath at 60 ° C for 4 hours, and then ultrasonically disperse for 2 hours to fully disperse the carbon nanotubes in the DMF solvent , to obtain acidified carbon nanotube dispersion.

[0028]...

Embodiment 2

[0033] A porous polyvinylidene fluoride-carbon nanotube composite material is prepared by the following steps:

[0034] 1) Add 1 mg of multi-walled carbon nanotubes with a diameter of about 40 to 60 nm and a length of about 5 to 15 μm into a mixed acid of concentrated sulfuric acid (50 ml, concentration 98 wt %) and concentrated nitric acid (150 ml, concentration 68 wt %), After ultrasonic dispersion for 0.5 h, the temperature was raised to 60° C. and refluxed for 8 h, then poured into deionized water for dilution, and then subjected to suction filtration and drying to obtain black powder of acidified carbon nanotubes.

[0035]2) Add 2 mg of the obtained acidified carbon nanotubes and 1 ml of polyethylene glycol-400 into 20 ml of DMF (N-N dimethylformamide) solvent, heat and stir in a water bath at 50° C. for 2 h, and then ultrasonically disperse for 1 h to make the carbon The nanotubes are fully dispersed in the DMF solvent to obtain an acidified carbon nanotube dispersion. ...

Embodiment 3

[0040] A porous polyvinylidene fluoride-carbon nanotube composite material is prepared by the following steps:

[0041] 1) Add 500 mg of multi-walled carbon nanotubes with a diameter of about 40 to 60 nm and a length of about 5 to 15 μm into a mixed acid of concentrated sulfuric acid (50 ml, concentration 98 wt %) and concentrated nitric acid (150 ml, concentration 68 wt %), After ultrasonic dispersion for 50 minutes, the temperature was raised to 70° C. and refluxed for 7 hours, then poured into deionized water for dilution, and then subjected to suction filtration and drying to obtain a black powder of acidified carbon nanotubes.

[0042] 2) Add 300 mg of the obtained acidified carbon nanotubes and 1.5 ml of polyethylene glycol-800 into 30 ml of DMF solvent, heat and stir in a water bath at 60°C for 3 hours, and then ultrasonically disperse for 1.5 hours to fully disperse the carbon nanotubes in DMF solvent to obtain acidified carbon nanotube dispersion.

[0043] 3) Add 2.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com