Pipeline outer anticorrosion layer protective material

A technology of protective material and anti-corrosion layer, applied in the field of pipeline system, can solve the problems of peeling off the protective layer, insufficient adhesion, insufficient scratch resistance of the protective layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

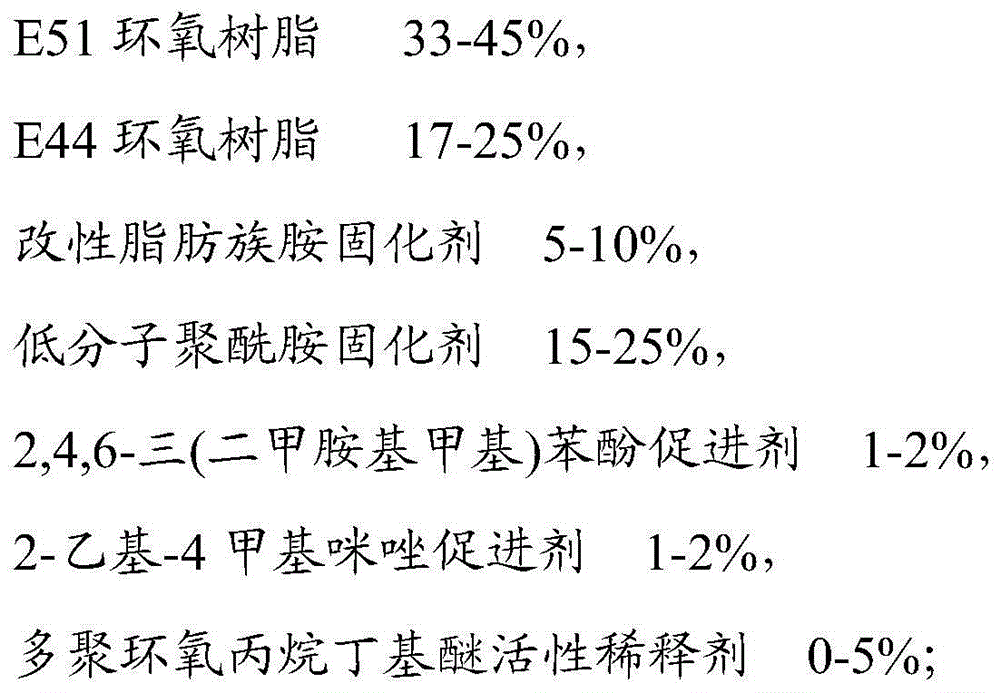

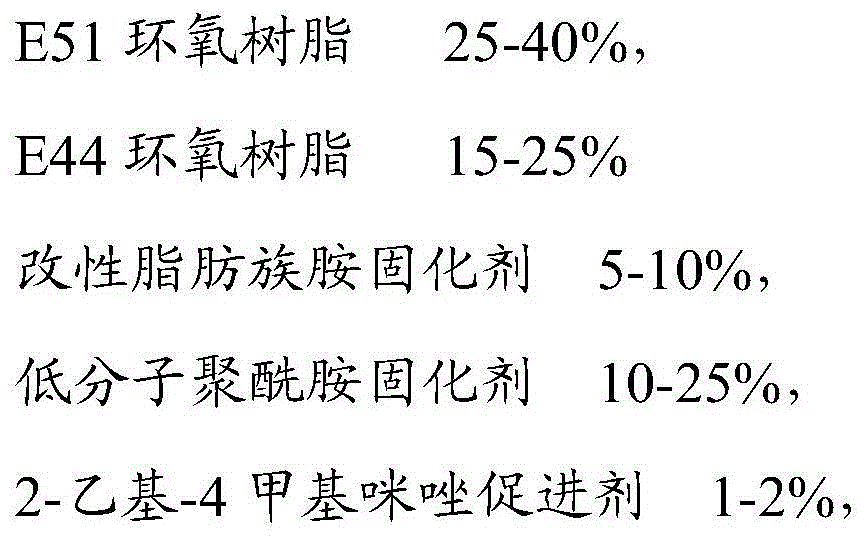

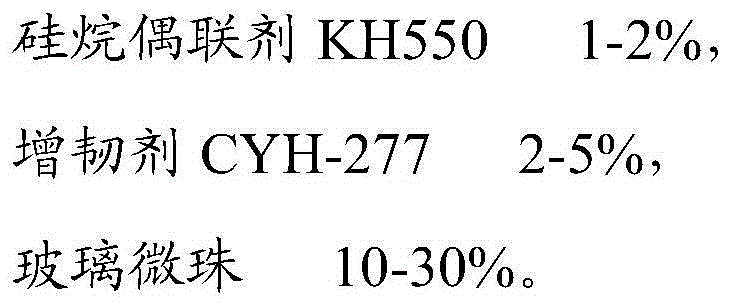

[0030] This embodiment provides a protective material for the outer anti-corrosion layer of a pipeline, which includes a protective layer covering the outside of the pipeline and a putty system at both ends of the protective layer. The protective layer includes a resin system and a fiber reinforcement. The resin system includes the following components in mass percentage: E51 epoxy resin 35%, E44 epoxy resin 25%, modified aliphatic amine curing agent 10%, low molecular polyamide curing agent 21%, 2,4,6 - Tris(dimethylaminomethyl)phenol accelerator 2%, 2-ethyl-4 methylimidazole accelerator 2%, polypropylene oxide butyl ether reactive diluent 5%. The fiber reinforcement used is 200g / m 2 Carbon fiber jersey. The putty system includes the following components in mass percentage: 30% of E51 epoxy resin, 20% of E44 epoxy resin, 5% of modified aliphatic amine curing agent, 10% of low molecular weight polyamide curing agent, 2-ethyl- 4 Methylimidazole accelerator 1%, silane coupling...

Embodiment 2

[0032] This embodiment provides a protective material for the outer anti-corrosion layer of a pipeline, which includes a protective layer covering the outside of the pipeline and a putty system at both ends of the protective layer. The protective layer includes a resin system and a fiber reinforcement. The resin system includes the following components in mass percentage: E51 epoxy resin 43%, E44 epoxy resin 20%, modified aliphatic amine curing agent 6%, low molecular polyamide curing agent 25%, 2,4,6 - Tris(dimethylaminomethyl)phenol accelerator 1%, 2-ethyl-4 methylimidazole accelerator 2%, polypropylene oxide butyl ether reactive diluent 3%. The fiber reinforcement used is 200g / m 2 Fiberglass twill. The putty system includes the following components in mass percentage: 35% of E51 epoxy resin, 15% of E44 epoxy resin, 10% of modified aliphatic amine curing agent, 15% of low molecular weight polyamide curing agent, 2-ethyl- 4 Methylimidazole accelerator 2%, silane coupling ag...

Embodiment 3

[0034] This embodiment provides a protective material for the outer anti-corrosion layer of a pipeline, which includes a protective layer covering the outside of the pipeline and a putty system at both ends of the protective layer. The protective layer includes a resin system and a fiber reinforcement. The resin system includes the following components in mass percentage: E51 epoxy resin 45%, E44 epoxy resin 18%, modified aliphatic amine curing agent 9%, low molecular polyamide curing agent 20%, 2,4,6 - Tris(dimethylaminomethyl)phenol accelerator 2%, 2-ethyl-4 methylimidazole accelerator 1%, polypropylene oxide butyl ether reactive diluent 5%. The fiber reinforcement used is 200g / m 2 Ultra-high molecular weight polyethylene fiber non-weft fabric. The putty system includes the following components in mass percentage: 40% of E51 epoxy resin, 15% of E44 epoxy resin, 6% of modified aliphatic amine curing agent, 25% of low molecular weight polyamide curing agent, 2-ethyl- 4 Methy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com