UL94-5VA-grade high-GWIT (Glow Wire Ignition Temperature) reinforcing PA66 material and preparation method thereof

A technology of PA66 and raw materials, which is applied in the field of high GWIT reinforced PA66 materials and its preparation, can solve the problems of not being able to meet the production of thin-walled parts, poor compatibility of PPO, and affecting the scope of use, so as to achieve easy process operation and low cost. Low, good color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of a UL94-5VA grade high GWIT reinforced PA66 material, comprising steps:

[0034] 1) fully dry PA66;

[0035] 2) Mix fully dried PA66 and other raw materials except glass fiber;

[0036] 3) Put the mixture obtained in the previous step into a twin-screw extruder to extrude and granulate, and at the same time add glass fiber to the fifth zone of the extruder, and water-cool and granulate.

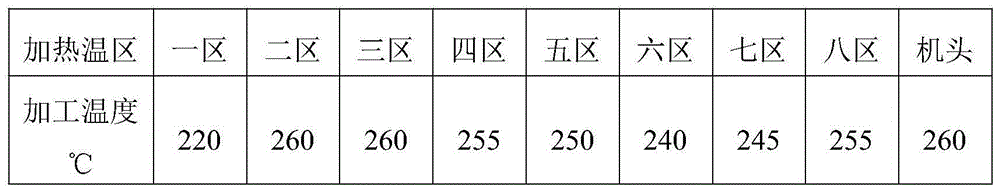

[0037] Preferably, the rotating speed of the screw of extruder is 250~300r / min; The temperature of each zone of extruder is as follows:

[0038] Table 1: Temperature of each zone of the extruder

[0039]

[0040] Raw material description for comparative examples and examples: Among them, PA66 is Shenma’s EPR24, PPO is Bluestar LXR040, brominated flame retardant is decabromodiphenylethane, and compound flame retardant is phosphate flame retardant PX -200, 3.5 hydrated zinc borate, barium metaborate, nitrogen flame retardant MCA-12 compounded according to 1:1...

Embodiment 1

[0043] A UL94-5VA grade high GWIT reinforced PA66 material, its formula composition is as follows:

[0044] Table 2: Formula composition of UL94-5VA grade high GWIT reinforced PA66 material

[0045] raw material

Embodiment 2

[0047] A UL94-5VA grade high GWIT reinforced PA66 material, its formula composition is as follows:

[0048] Table 3: Formula composition of UL94-5VA grade high GWIT reinforced PA66 material

[0049] raw material

[0050] PP0

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com