Cationic photocurable coating for transfer film

A technology of light-curing coatings and cations, applied in coatings and other directions, can solve the problems of poor scratch resistance and wear resistance of coatings, unclear transfer patterns, and no protective effect, so as to improve hardness, wear resistance, and fullness Good, strong aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the thermally curable acrylate used in the present invention can be:

[0022] 1. React one isocyanate group of hydroxyacrylate and polyisocyanate, the molar ratio of hydroxyacrylate and polyisocyanate is 1:1, add dibutyltin dilaurate (DBTDL) accounting for 0.05% of the mass of polyisocyanate as a catalyst, React under anhydrous conditions for 10h, the reaction temperature is 40°C; the infrared spectrum of hydroxyacrylate is 3300cm -1 The characteristic absorption peak of the hydroxyl group at the place disappears; then the reaction is completed, and a heat-curable acrylate is obtained for use;

[0023] 2. At room temperature, weigh epoxy resin, heat-curable acrylate, cationic photoinitiator, free radical photoinitiator and auxiliary agent according to their respective proportions, and mix them evenly to obtain the cationic photoinitiator used for the transfer film Light-curing coating, ready for use;

[0024] Among them, the epoxy resin is bi...

specific Embodiment 1-10

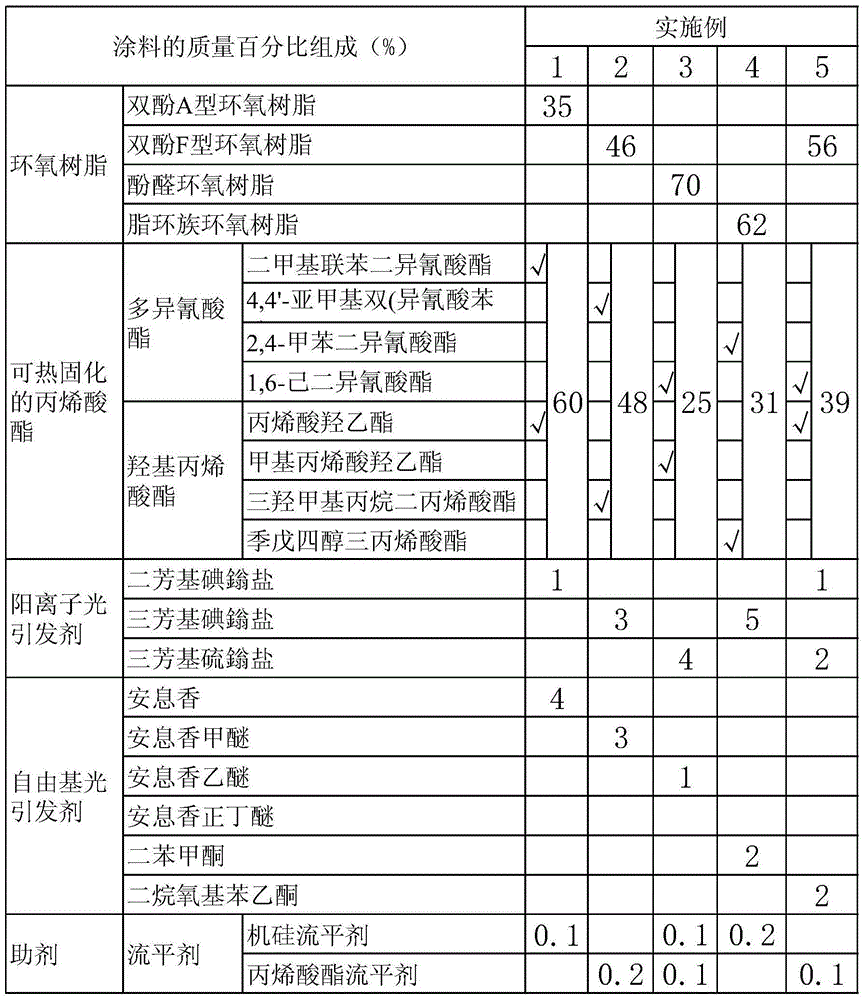

[0031] Concrete embodiment 1-10 sees table 1 and table 2:

[0032] Table 1

[0033]

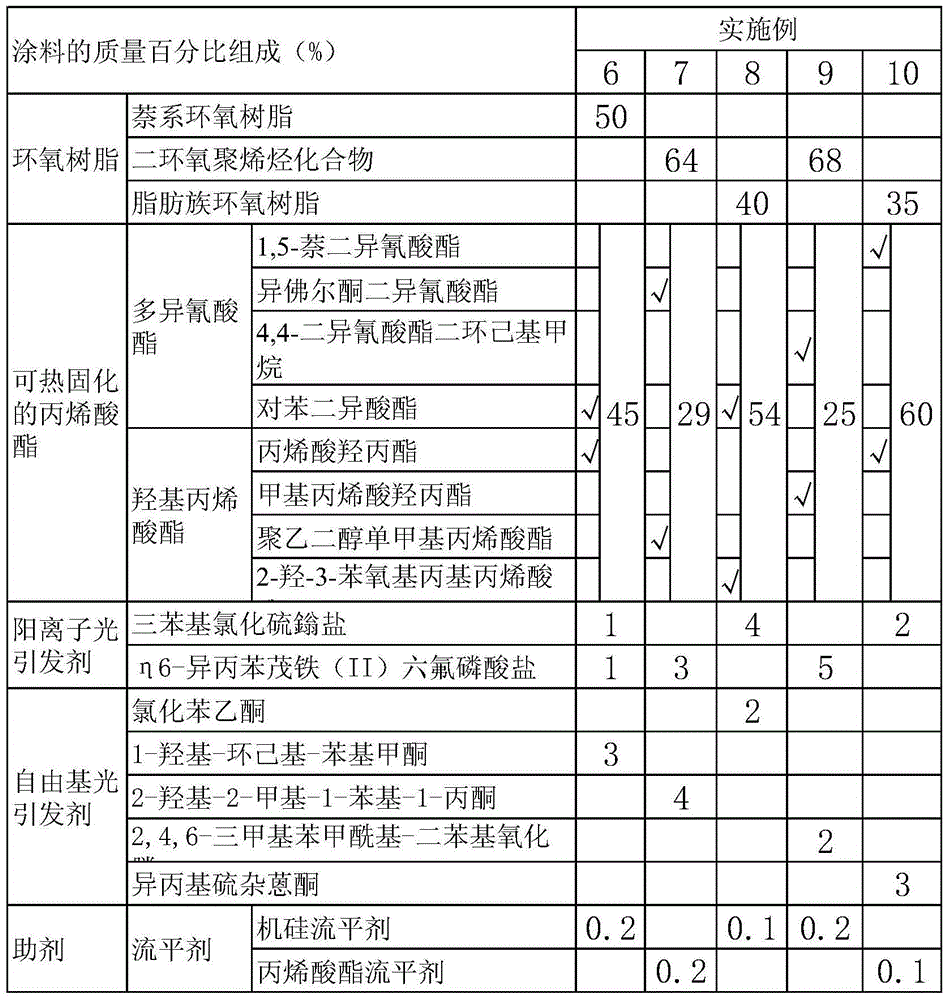

[0034] Table 2

[0035]

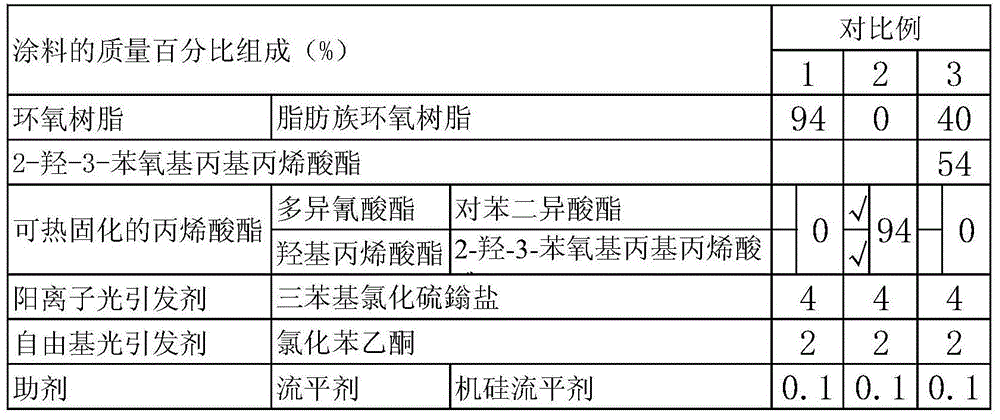

[0036] Comparative examples 1-3 are shown in Table 3:

[0037] table 3

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com