A kind of coating combination for motor car head

A car head and coating technology, which is applied in coatings, metal material coating technology, anti-corrosion coatings, etc., can solve problems such as deformation, high operating costs, and large differences in erosion angles, so as to increase service life and improve anti-corrosion Scratch ability, improve the effect of frontal erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

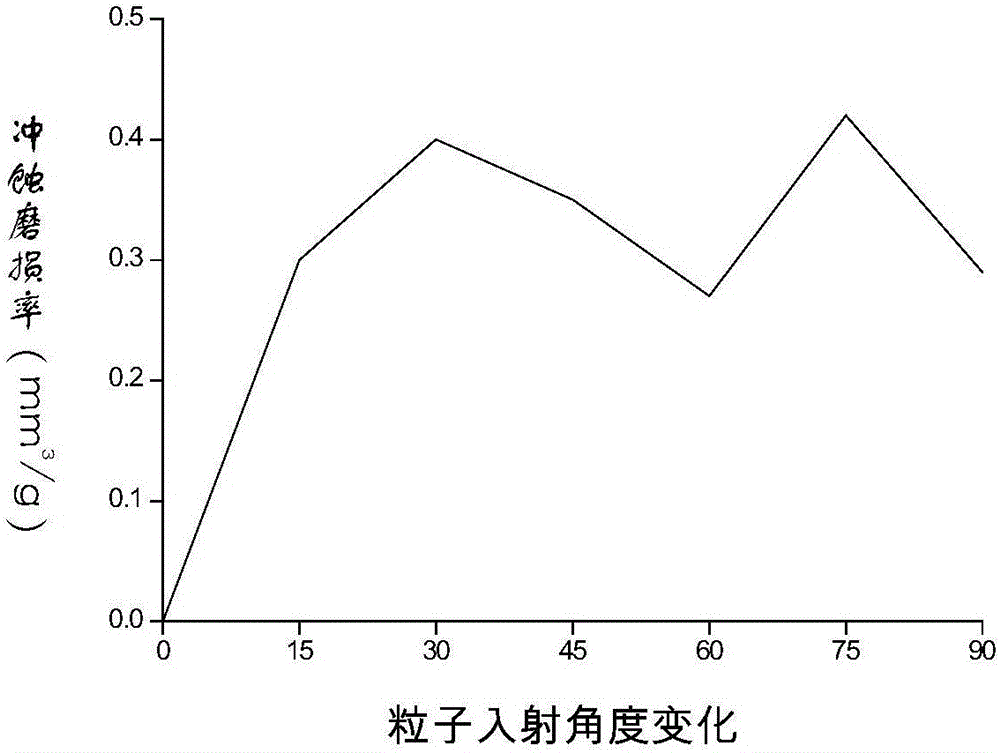

[0051] The erosion experiment was carried out on the existing polyurethane composite coating system, and the experimental parameters were set as follows: the particle speed was 100m / s, the feeding speed was 3.00g / min, and the particle size was about 100μm.

[0052] The experimental results show that the erosion volume wear rate of the coating is above 0.30mm3 / g no matter in small-angle erosion or frontal erosion. For specific experimental results, see figure 2 .

Embodiment 2

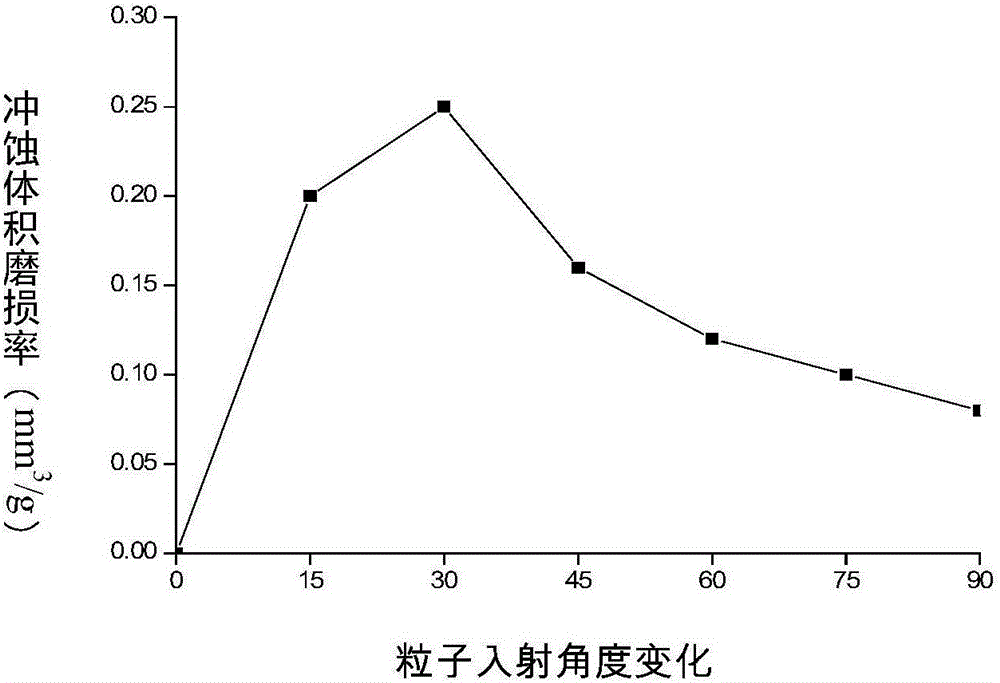

[0054] A 60 μm (dry film thickness) two-component epoxy resin primer was sprayed on the aluminum alloy substrate, followed by spraying a 30 μm thick two-component polyurethane primer and a 100 μm thick modified polyurethane topcoat on it to prepare the test In this way, the erosion test was carried out.

[0055] The experimental parameters are set as follows: the particle speed is 100m / s, the feeding speed is 3.00g / min, the particle size is about 100μm, and the incident angle of the particles is changed to obtain the change curve of the erosion and wear rate of the modified polyurethane coating with the incident angle, as shown in image 3 shown.

[0056] The erosion wear at 30° incidence is the largest, and the erosion wear rate is 0.25mm 3 / g, the erosion wear rate is only 0.08mm when the impact is frontal at 90° 3 / g.

Embodiment 3

[0058] A WC-Co cermet coating with an average thickness of about 100 μm was prepared on the surface of aluminum alloy substrate by thermal spraying method, and the erosion experiment was carried out.

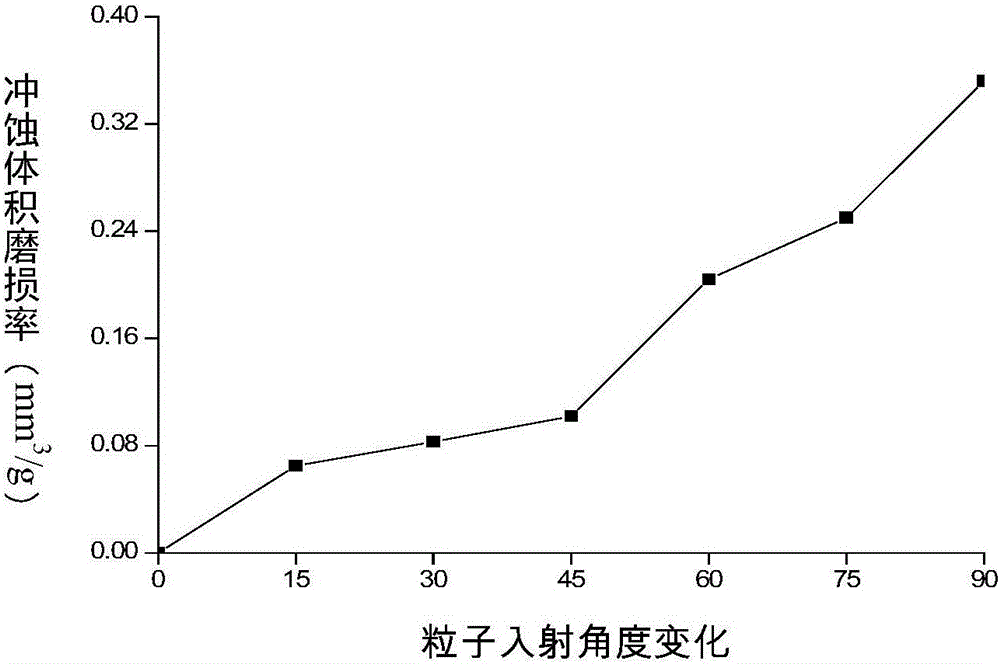

[0059] The experimental parameters are set as follows: the particle speed is 100m / s, the feeding speed is 3.00g / min, the particle size is about 100μm, and the incident angle of the particles is changed to obtain the change curve of the erosion wear rate of the WC-Co cermet coating with the incident angle ,Such as Figure 4 shown.

[0060] The erosion wear rate of the frontal impact of 90° incidence is the largest, which is 0.4mm 3 / g, but the 30° incident erosion wear rate is only 0.083mm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com