Mining dust removal foam generating agent

A technology for foam generation and mine use, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of inability to guarantee safe dust removal in high-gas mines, unsatisfactory dust removal effect, etc., to achieve wide use of corrosion and strong foam stability , the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

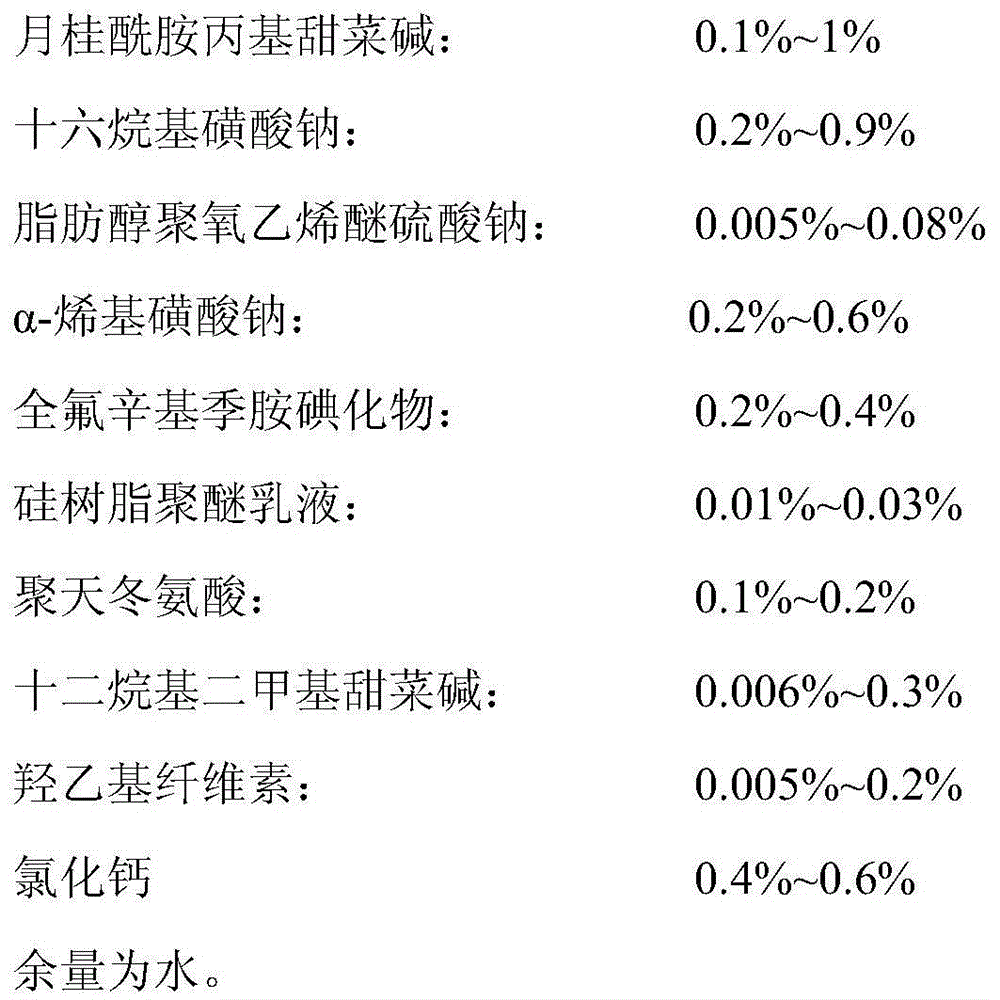

[0034] Weigh respectively according to the following quality standards: 1 kg of lauryl amidopropyl betaine, 2 kg of sodium cetyl sulfonate, 0.05 kg of sodium fatty alcohol polyoxyethylene ether sulfate, 2 kg of sodium α-alkenyl sulfonate, 2 kg of perfluorooctyl quaternary Ammonium iodide 2kg, silicone resin polyether emulsion 0.1kg, polyaspartic acid 1kg, dodecyl dimethyl betaine 0.06kg, hydroxyethyl cellulose 0.05kg, calcium chloride 4g. Add the above formula raw materials into 987.74kg of clear water, and prepare and form 1000kg of mine dust-removing foam generating agent after fully mixing. The foam generated by the mine dedusting foam generating agent has uniform texture and good stability.

[0035]Among them, in this formula, the percentages of various raw materials are: lauryl amidopropyl betaine 0.1%; sodium cetyl sulfonate 0.2%; fatty alcohol polyoxyethylene ether sodium sulfate 0.005%; Sodium Sulfonate 0.2%, Perfluorooctyl Quaternary Ammonium Iodide 0.2%, Silicone Po...

Embodiment 2

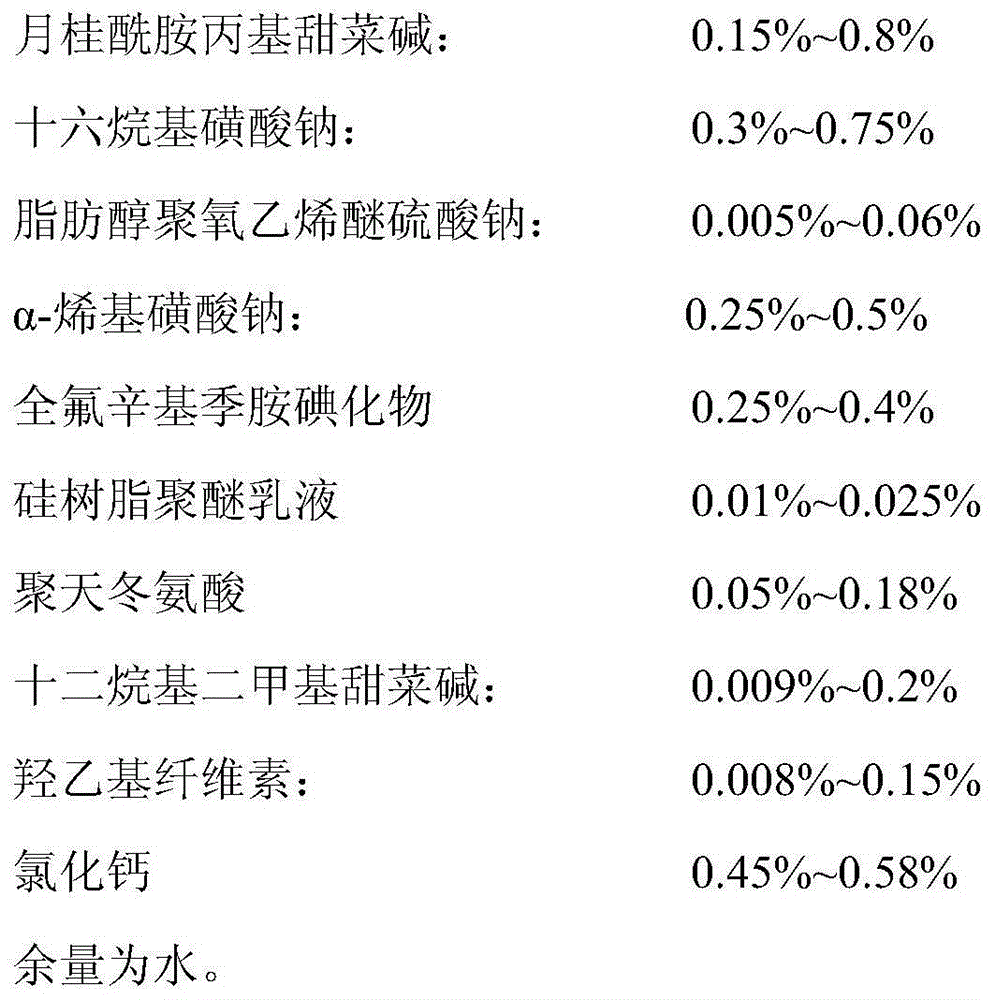

[0037] Weigh respectively according to the following quality standards: 1.5 kg of lauryl amidopropyl betaine, 3 kg of sodium cetyl sulfonate, 0.05 kg of sodium fatty alcohol polyoxyethylene ether sulfate, 2.5 kg of sodium α-alkenyl sulfonate, and 2.5 kg of perfluorooctyl quaternary ammonium iodide 2.5kg, silicone resin polyether emulsion 0.1kg, polyaspartic acid 0.5kg, dodecyl dimethyl betaine 0.09kg, hydroxyethyl cellulose 0.08kg, calcium chloride 4.5g. Add the above formula raw materials into 985.18kg of clear water, and prepare and form 1000kg of mining dust-removing foam generating agent after fully mixing. The foam generated by the mine dedusting foam generating agent is large in quantity, uniform and delicate, has a certain viscosity and high stability.

[0038] Among them, in this formula, the percentages of various raw materials are: lauryl amidopropyl betaine 0.15%; sodium cetyl sulfonate 0.3%; fatty alcohol polyoxyethylene ether sodium sulfate 0.005%; Sodium Sulfona...

Embodiment 3

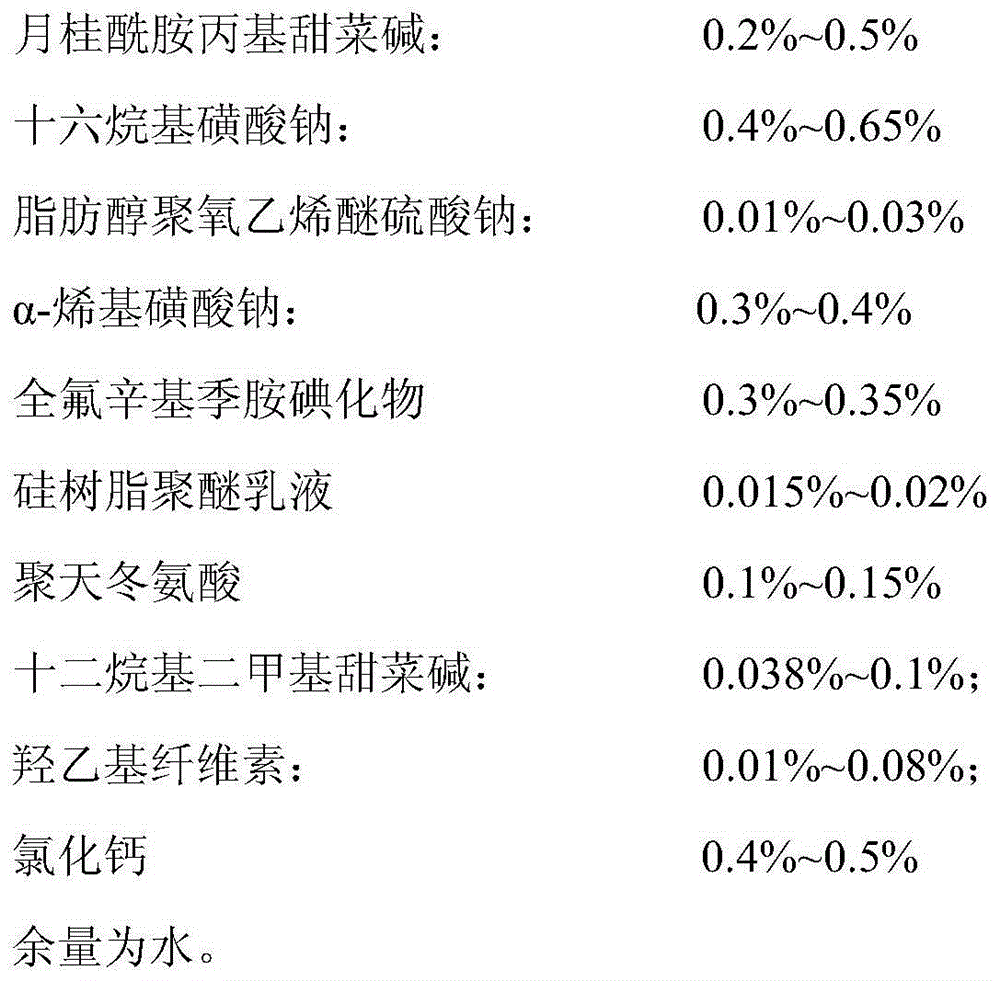

[0040] Weigh respectively according to the following quality standards: 2.8 kg of lauryl amidopropyl betaine, 4.2 kg of sodium cetyl sulfonate, 0.11 kg of sodium fatty alcohol polyoxyethylene ether sulfate, 3.5 kg of sodium α-alkenyl sulfonate, Octyl quaternary ammonium iodide 3.2kg, silicone resin polyether emulsion 0.18kg, polyaspartic acid 1.2kg, dodecyl dimethyl betaine 0.09kg, hydroxyethyl cellulose 0.1kg, calcium chloride 4g. Add the above formula raw materials into 980.62kg of clear water, and prepare and form 1000kg of mining dust-removing foam generating agent after fully mixing. The foam generated by the mine dedusting foam generating agent has uniform texture and good stability.

[0041] Among them, in this formula, the percentages of various raw materials are: lauryl amidopropyl betaine 0.28%; sodium cetyl sulfonate 0.42%; fatty alcohol polyoxyethylene ether sodium sulfate 0.011%; Sodium Sulfonate 0.35%, Perfluorooctyl Quaternary Ammonium Iodide 0.32%, Silicone Po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com