Grate type incinerator and treatment process for domestic waste

A domestic garbage and incinerator technology, applied in the field of incinerators, can solve the problems of high operating cost, large investment, complex process, etc., and achieve the effects of low operating cost, low energy consumption, and low power for equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

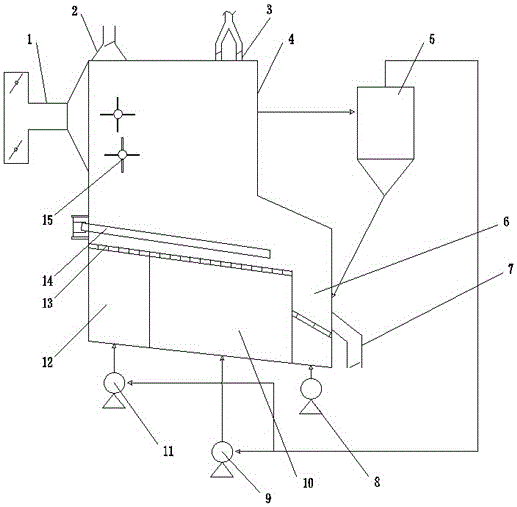

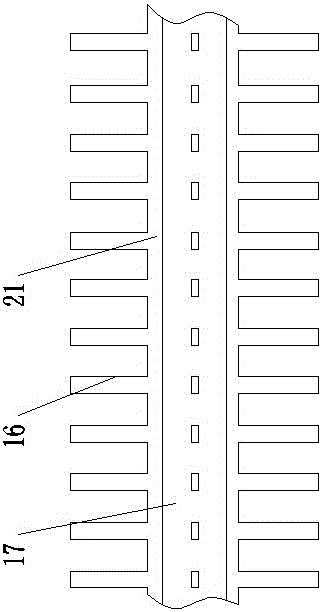

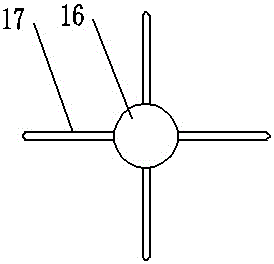

[0028] See attached Figure 1-5 , This incinerator for processing domestic waste disclosed in the present invention utilizes the tertiary air of the cement kiln and part of the gas in the kiln tail smoke chamber as a heat source. This incinerator mainly includes a furnace body 4 and a dust collector 5 connected to the furnace body. The furnace body is provided with an air induction pipe 1, a feeding device 2, an exhaust pipe 3 and a discharge device 7 communicating with the inside of the furnace body. Regulating valves are respectively installed inside. The air induction pipe is connected with the tertiary air pipe of the cement kiln and the kiln tail smoke chamber. The air induction pipe, the exhaust pipe and the inner wall of the furnace are built with refractory materials. Part of the gas in the kiln tail smoke chamber is used as one of the heat s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com