Airport apron pipe network impermeability testing device and method based on pressure correlation method

A testing device and airtightness technology, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the fluid's acceleration and deceleration rate. , feasibility, low accuracy, short distance of the apron pipe network, etc., to achieve the effect of rich display content, simple calculation and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the purpose and technical solution of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

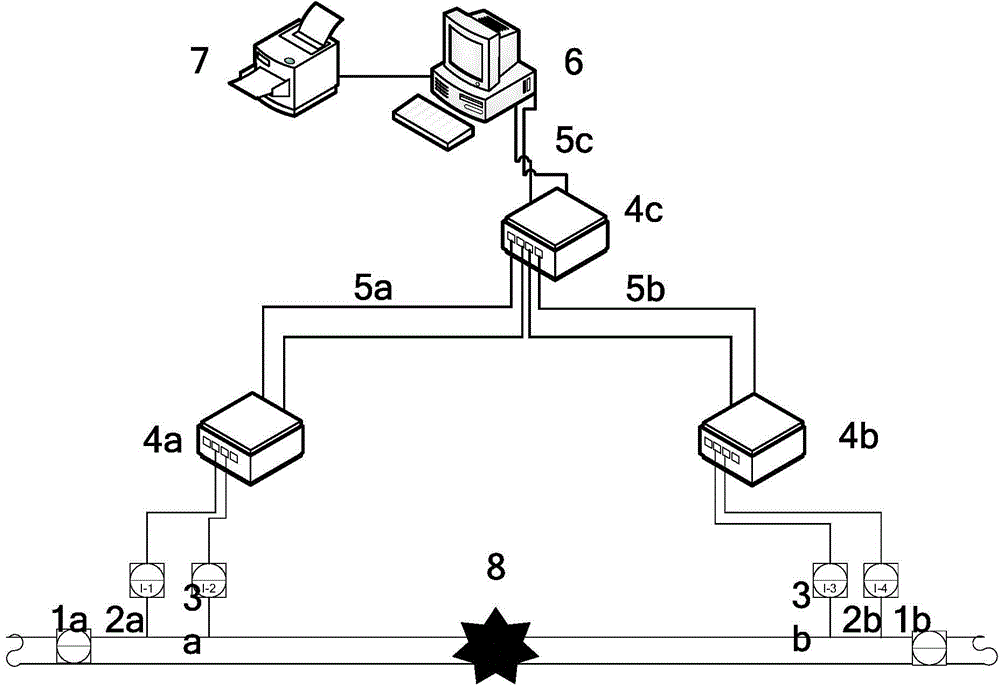

[0047] as attached figure 1 As shown, a test device for the airtightness of the apron pipe network based on the pressure correlation method includes a simulation test component, a transmitter group, a data collector (4a, 4b and 4c), and a data transmission medium (5a, 5b and 5c) and monitoring host 6.

[0048] Precision cut-off valves (1a and 1b) are used to cut off the pipe section to be tested, and form a simulated test assembly with the charging pump, pressure relief valve and leakage valve, and oil recovery device.

[0049] The pressure transmitter 2a and the temperature transmitter 3a form the first transmitter group; the pressure transmitter 2b and the temperature transmitter 3b form the second transmitter group. Install the first set of transmitter sets at the beginni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com