Seepage field-temperature field simulation coupling material bin and TBM cutting test stand

A cutting test and material silo technology, which is used in the analysis of materials, strength properties, test machinability, etc., can solve the problems such as the inability to leave the free surface of the rock sample and the small size of the rock and soil sample, and achieve reasonable structure and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

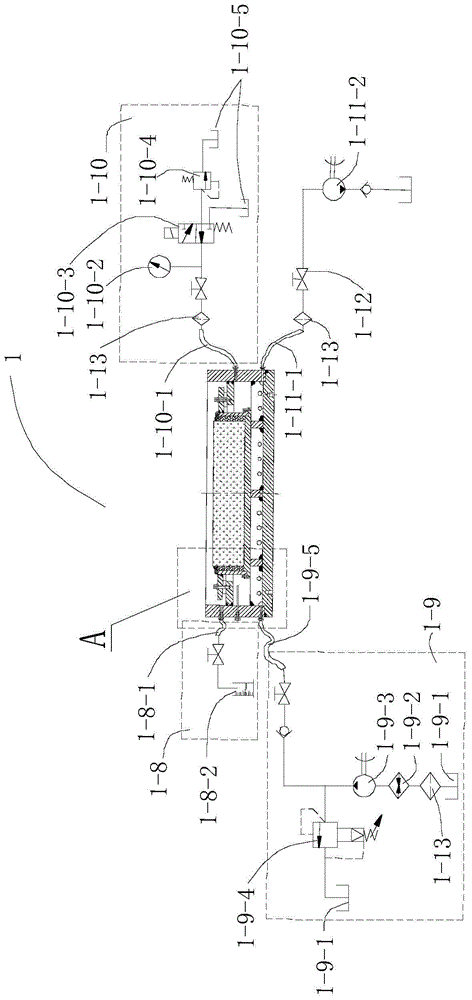

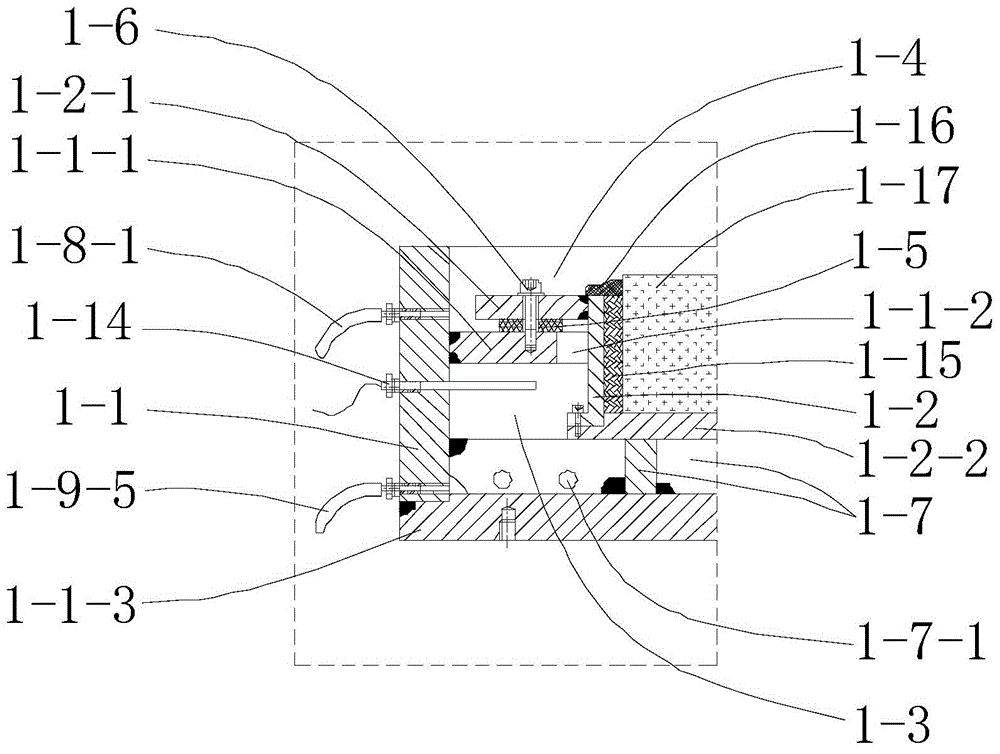

[0067] See attached figure 1 , 2 , a seepage field-temperature field simulation coupling material bin (1) of the present invention, comprising: a material bin main body (1-1), a material mounting seat (1-2), a seepage collection branch (1-8), a heating water injection Branch (1-9), backwater pressure maintaining branch (1-10);

[0068] A first platform (1-1-1) is provided along the inner wall of the main body (1-1) of the material bin, and a through hole (1-1-2) is formed in the center of the first platform (1-1-1). The outer wall of the mounting seat (1-2) is provided with a second platform (1-2-1) in the circumferential direction, and the cross-sectional shape of the material mounting seat (1-2) is matched with the through hole (1-1-2) and embedded In the through hole (1-1-2), the second platform (1-2-1) provided on the outer wall is used to contact the first platform (1-1-1) provided on the inner wall of the material bin to make the material mounting seat ( 1-2) Position...

Embodiment 2

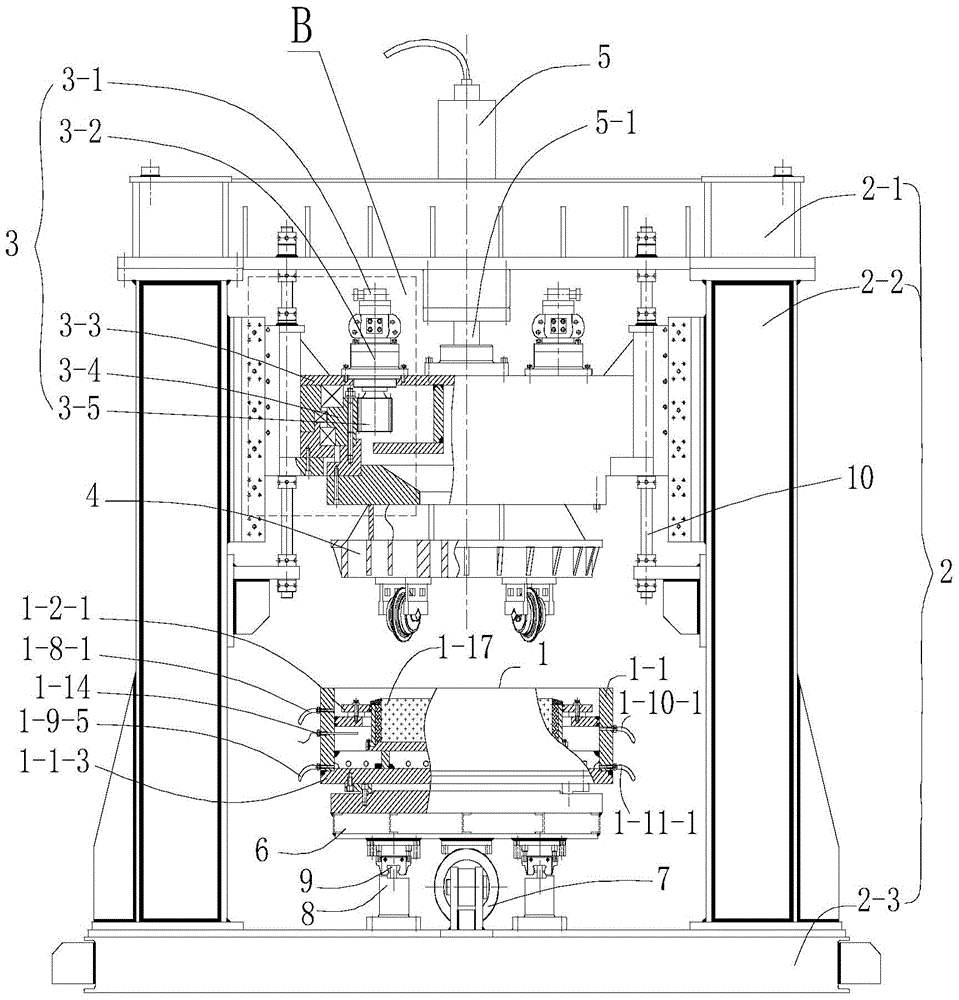

[0081] See attached image 3 , 4 , 5, a kind of TBM cutting test bench of the present invention, cutting test bench comprises seepage field-temperature field simulation coupling material bin (1), main frame (2), power transmission device (3) and cutter head system (4);

[0082] The main frame (2) comprises a beam (2-1), a column (2-2) and a base (2-3); one end of the column (2-2) is symmetrically installed on the base (2-3), and the other end A beam (2-1) is installed;

[0083] The cutter head system (4) is installed under the power transmission device (3);

[0084] A vertical oil cylinder (5) is installed on the crossbeam (2-1), and the end of its piston rod (5-1) is connected with the power transmission device (3) to drive the power transmission device (3) to work with the cutter head system (4). vertical movement;

[0085] The seepage field-temperature field simulation coupling material bin (1) is installed on the longitudinal moving base (6), and the longitudinal movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com