A cross-correlation eddy current thermal imaging defect detection and tomography method and system

A technology of defect detection and tomography, which is applied in the fields of structural health monitoring, product quality control, material characterization evaluation, and equipment non-destructive testing. problem, achieving enhanced defect detection and tomographic imaging results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiments of the present invention are described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention.

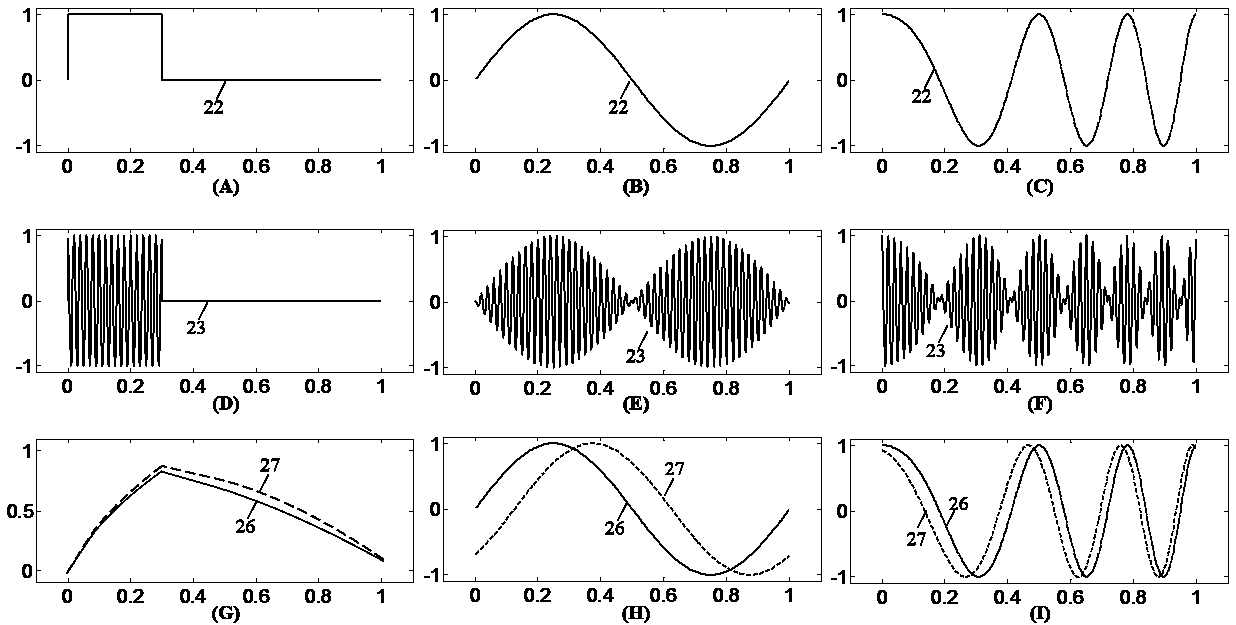

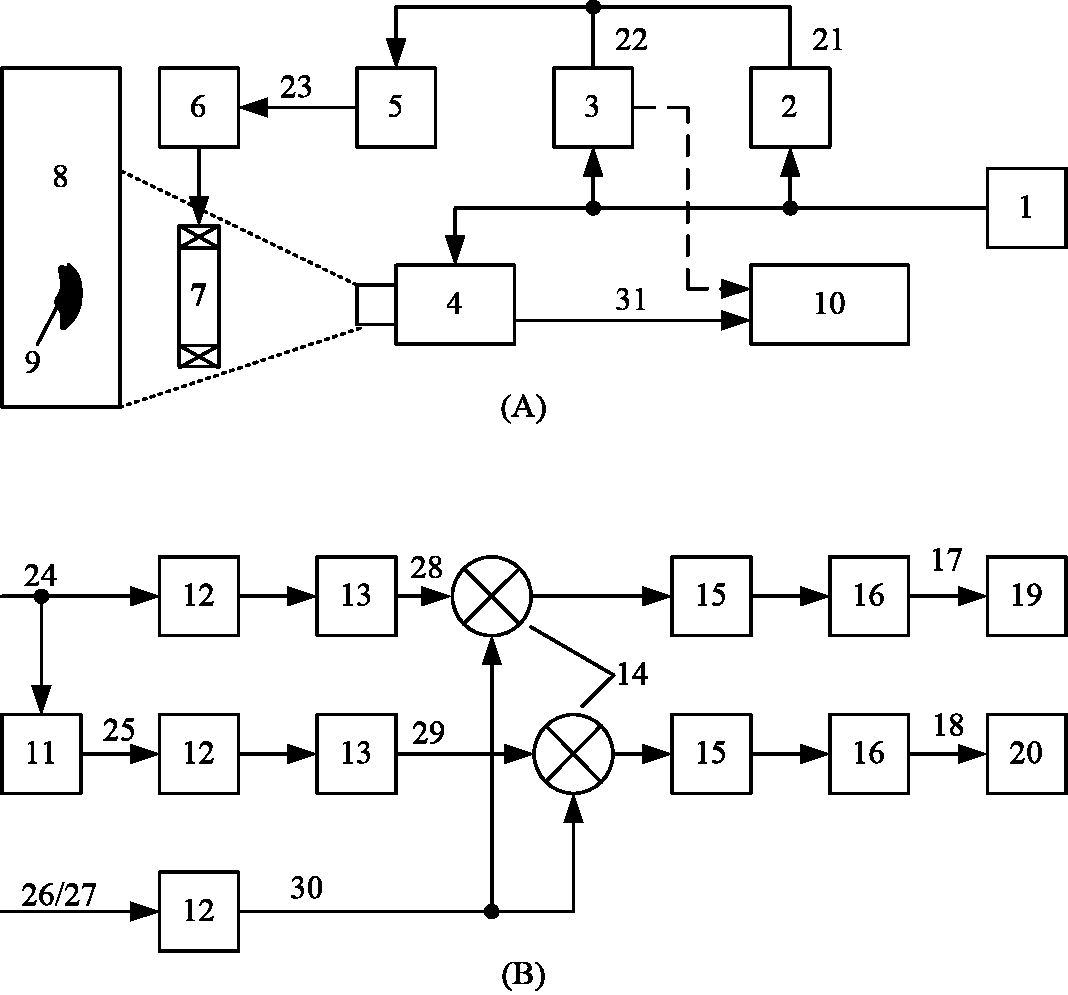

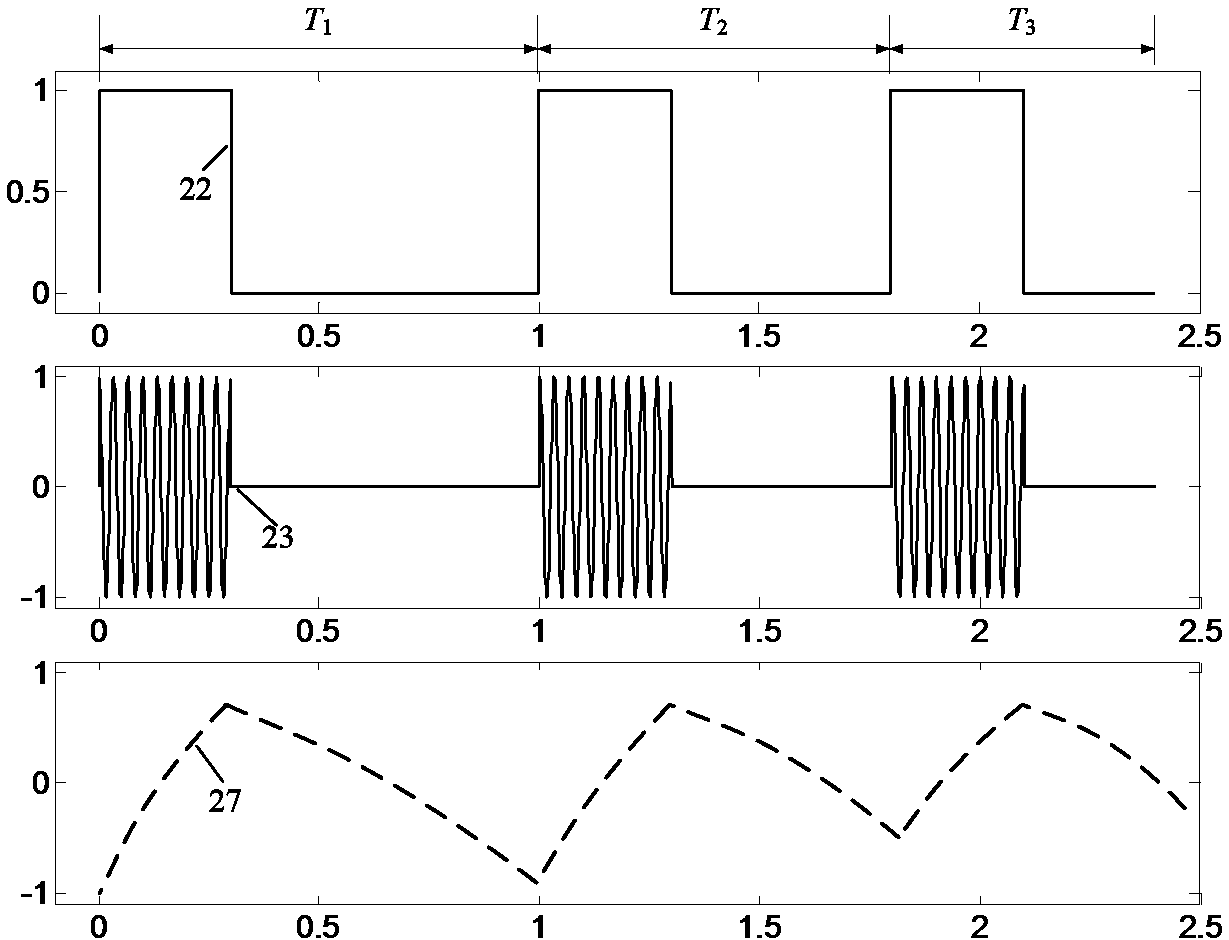

[0047] figure 1 It is a schematic diagram of a cross-correlation eddy current thermal imaging defect detection and tomography system, which mainly includes: controller 1, high frequency current generation module 2, modulation signal generation module 3, thermal imager 4, modulation module 5, drive module 6, Heating coil 7, inspected object 8, defect 9, computer 10, Hilbert transform 11, fast Fourier transform 12, complex conjugate operation 13, multiplication operation 14, inverse fast Fourier transform 15, real part operation 16, in-phase 17, quadrature 18, amplitude 19, phase 20, high-frequency AC signal 21, modulation signal 22, excitation signal 23, in-phase reference signal 24, quadrature reference signal 25, defect-free area detection signal 26, detection signal 27. Frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com