Modified plastic production line control method based on integrated communication

A control method and production line technology, applied in the manufacturing field, can solve the problems of ignorance of the production line operation, slow production progress, inaccurate sampling time, etc., and achieve the effects of reducing inaccurate sampling information, reducing labor intensity, and having a reasonable and reliable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention will be further described below in conjunction with specific implementation examples.

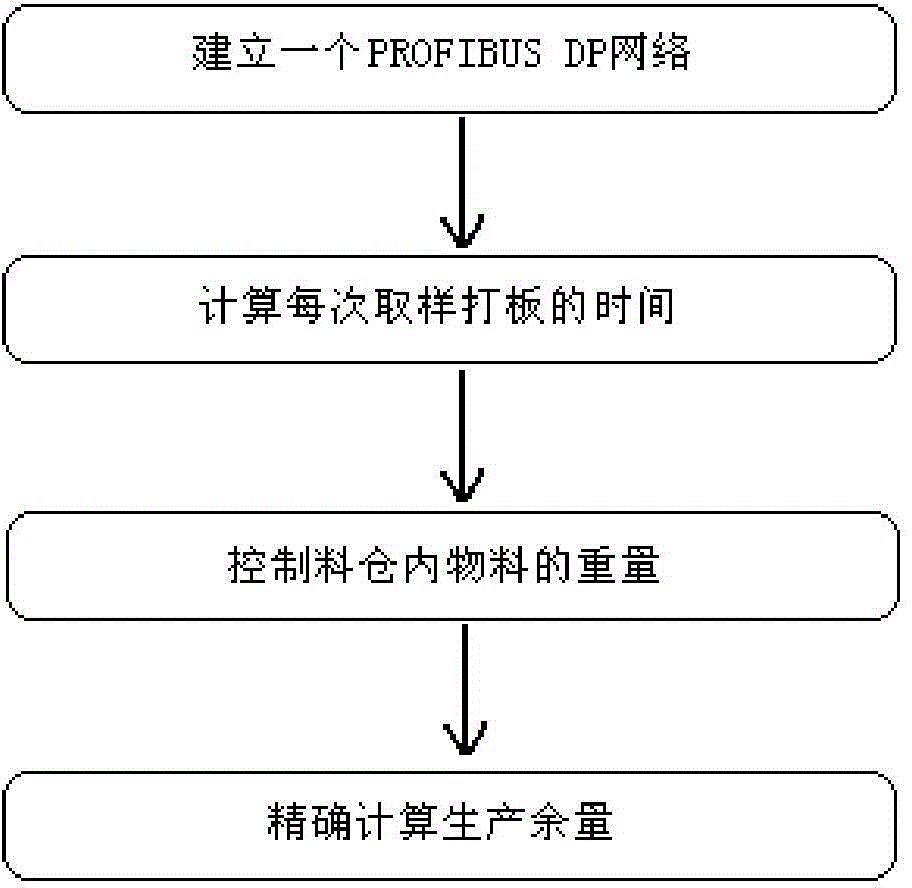

[0023] Method steps of the present invention are as figure 1 shown, where:

[0024] The high-speed mixer of modified plastic production equipment is controlled by Siemens 300PLC, which is Siemens 314C-2DP, the extruder is controlled by Siemens 315-2DP, and the online color mixing machine is controlled by Siemens 200224XPCN. By establishing a PROFIBUS DP network, the extruder The PLC acts as the master station, and the PLC of the high-speed mixer and the online color mixing machine and the weighing scale act as the slave station to realize data exchange, and process the signals of the auxiliary equipment by connecting the operating signals of the auxiliary equipment to the PLC of the extruder.

[0025] One: Production line information:

[0026] The system of the present invention displays the operation screen of the entire production line through the man-machine interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com