Method for monitoring pouring and rolling construction quality of roller compacted concrete dam in real time

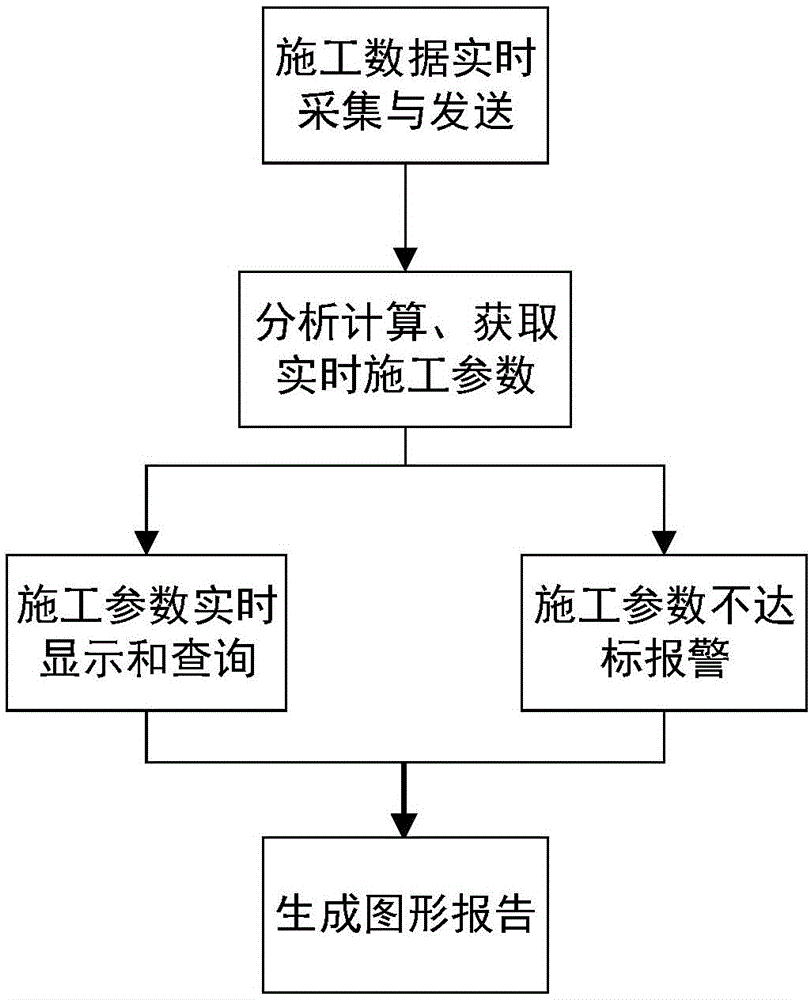

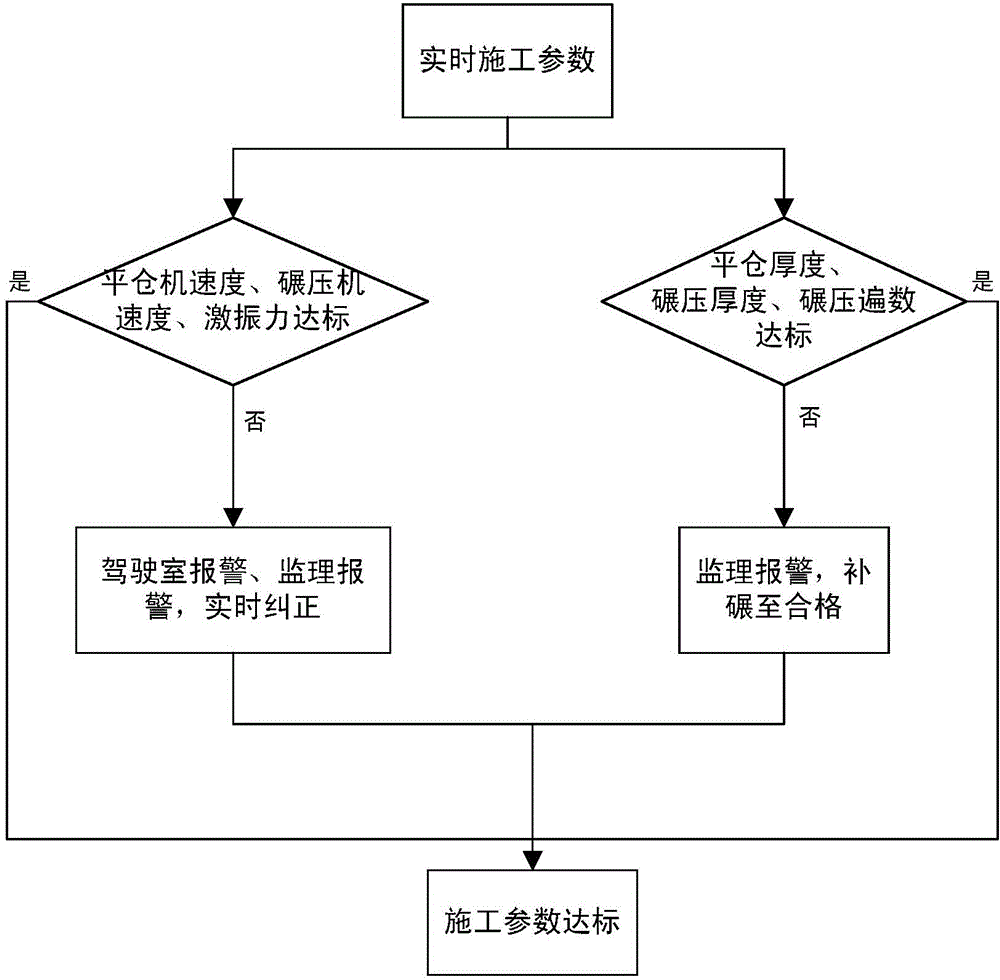

A technology of roller compacted concrete and construction quality, applied in the directions of comprehensive factory control, comprehensive factory control, program control, etc., can solve the problems of extensive management and large interference in the construction quality control of roller compacted concrete dams, so as to avoid extensive and improve the control level. and efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

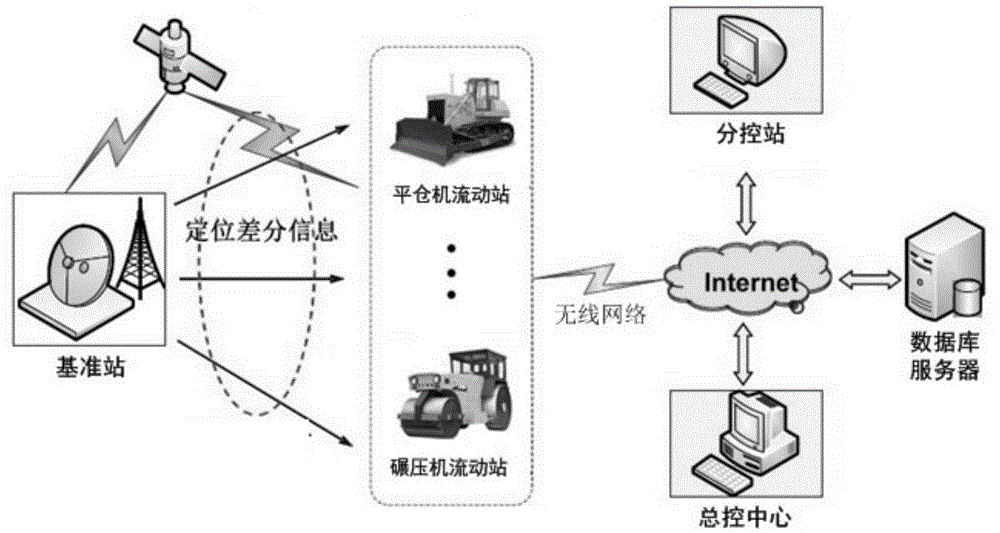

[0042] (1) Install a monitoring terminal integrated with a satellite antenna, high-precision GPS receiver, differential antenna, and wireless transmission module on the unwinding machine, and install an integrated satellite antenna, high-precision GPS receiver, differential antenna, and excitation force on the rolling machine The monitoring terminal of the induction device and the wireless transmission module. The above-mentioned unwinding machine and rolling machine equipped with a monitoring terminal are also called mobile stations. The high-precision GPS receiver locates the coordinates of the current unwinding machine and rolling machine in real time at a fixed time interval; the differential antenna receives the coordinate difference information sent by the GPS reference station, and corrects the current coordinates in real time; at the same time, through the excitation force monitoring equipment Obtain the vibration state of the rolling machine; the corrected coordinates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com