Discharging device and method applied to ion source

A discharge device and ion source technology, applied in the field of mass spectrometry analysis, can solve the problems of reducing the number of high-energy particles, uneven air intake, easy ignition, etc., and achieve the effects of improving service life, ensuring service life and reducing discharge voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

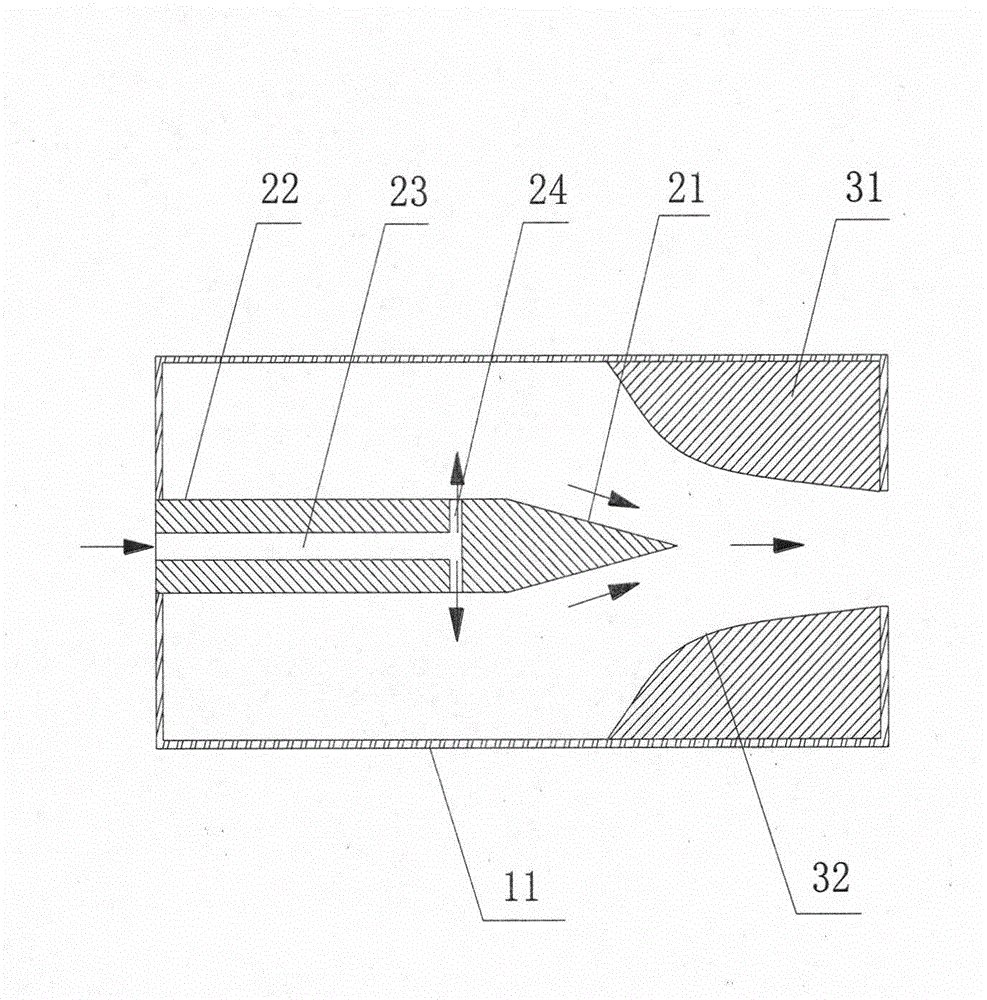

[0028] figure 1 Schematically presents a simplified structural diagram of a discharge device used in an on-site ion source under atmospheric pressure according to an embodiment of the present invention, as shown in figure 1 As shown, the discharge device includes:

[0029] The hollow container 11 is cylindrical; this component is a prior art in the art, and will not be described in detail here;

[0030] A discharge needle, the discharge needle is arranged in the container 11, including a tip portion 21 and a rear end portion 22, the tip portion 21 is conical; the inside of the rear end portion 22 has an axial hole 23 and a diameter that communicate with each other. To the holes 24, the radial holes 24 are evenly distributed; the discharge needle is made of single crystal silicon material;

[0031] Discharge cavity 31, the discharge cavity 31 is cylindrical, along the direction of the tip, the hollow part in the discharge cavity 31 gradually shrinks, and it is arranged on one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com