Olive juice and preparation method thereof

A technology of olive juice and olive juice, applied in the direction of food science, etc., can solve the problems of many chemical additives, poor taste, turbidity of fruit juice, etc., and achieve the effect of ensuring taste and quality, taste and quality, and food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

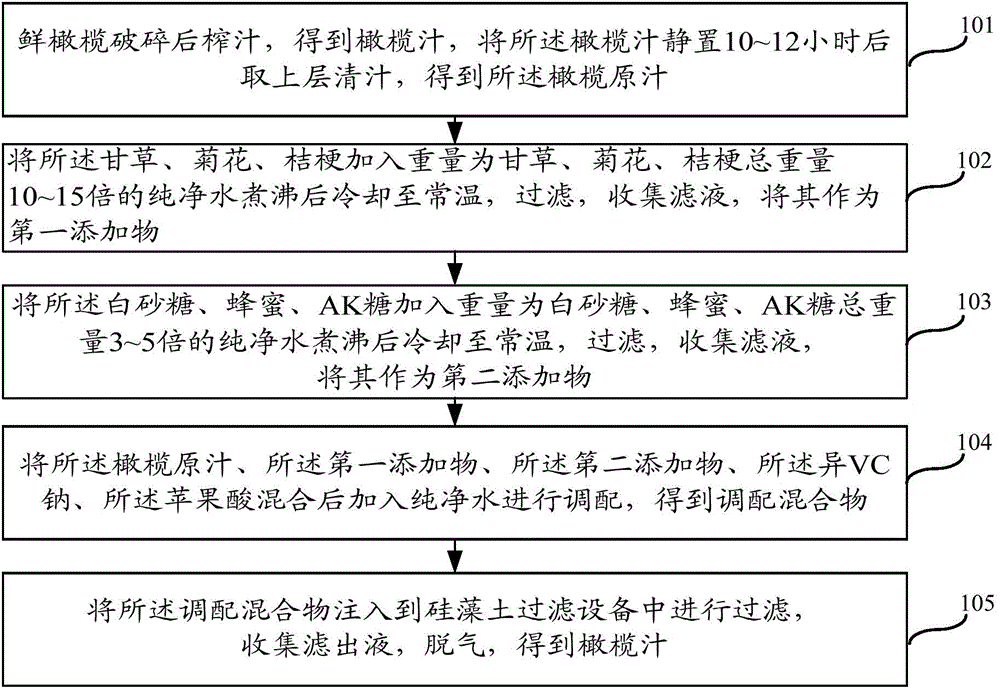

[0044] The preparation method of olive juice provided by the invention, such as figure 1 As shown, the following steps are included,

[0045] Step 101: fresh olives are crushed and squeezed to obtain olive juice, and the olive juice is left to stand for 10 to 12 hours, and then the upper clear juice is taken to obtain the original olive juice;

[0046] There is a longer clarification time when preparing olive juice, so that the precipitation reaction is more sufficient, and the precipitation removal after filtration is more thorough.

[0047] Preferably, in step 101, it also includes:

[0048] The clear juice of the upper layer is sterilized at 120-130° C. for 15-20 seconds, and then cooled to 30-40° C. to obtain the original olive juice.

[0049] The high-temperature instantaneous sterilization of olive juice can remove harmful microorganisms in olive juice without affecting the taste of olive juice, and completely retain the original nutrition and ingredients of olives.

...

Embodiment 1

[0069] Wild fresh olives remove impurities such as rotten fruit, leaves, fruit pedicles, wash the dust or fines on the fresh fruit with clean water, crush the fresh fruit with a crusher, and squeeze out the olive juice in the fresh fruit with a juicer; put the olive juice in Stand in the conical container for 10 hours to fully precipitate the pulp, seeds and other substances, and extract the supernatant juice; take the supernatant juice after precipitation and enter it into a high-temperature instant sterilizer, sterilize it at 120°C for 15 seconds, and then enter the cooling equipment to cool down to 30°C, prepare olive juice for later use.

[0070] Take 0.5kg of licorice, 0.3kg of chrysanthemum, and 0.5kg of platycodon grandiflora, add purified water with a weight 15 times the total weight of licorice, chrysanthemum, and platycodon grandiflorum, boil for 15 minutes, cool to room temperature, filter with 100-mesh gauze, collect the filtrate, and as the first addition.

[007...

Embodiment 2

[0074] Wild fresh olives remove impurities such as rotten fruit, leaves, fruit pedicles, wash the dust or fines on the fresh fruit with clean water, crush the fresh fruit with a crusher, and squeeze out the olive juice in the fresh fruit with a juicer; put the olive juice in Stand in the conical container for 15 hours to fully precipitate the pulp, seeds and other substances, and extract the supernatant juice; take the precipitated supernatant juice and enter it into a high-temperature instant sterilizer, sterilize it at 130°C for 20 seconds, and then enter the cooling equipment to cool down to 40°C, prepare olive juice for later use. Take 0.3kg of licorice, 0.5kg of chrysanthemum, and 0.5kg of platycodon grandiflora, add purified water with a weight 10 times the total weight of licorice, chrysanthemum, and platycodon grandiflorum, boil for 15 minutes, cool to room temperature, filter with 100-mesh gauze, collect the filtrate, and as the first addition.

[0075] Take 55kg of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com