Shell bursting device for camellia seed shells

A technology of camellia oleifera seeds and cracking shells, which is applied in the fields of application, shelling, and petroleum industry. It can solve problems such as long cracking time, poor working environment, and uneven shelling, and achieves reduced drying costs, labor intensity, and shortened drying time. The effect of shell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The above and other technical features and advantages of the present invention will be described in more detail below with reference to the accompanying drawings and embodiments.

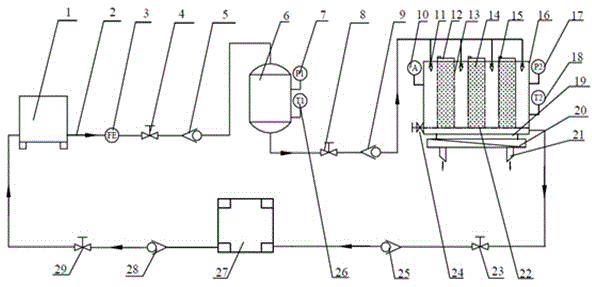

[0024] Such as figure 1 As shown, it is a structural schematic diagram of a shell-exploding device applied to the shell of camellia oleifera seeds in an embodiment of the present invention, including a steam generating module, a gas storage module, a shell-exploding module and a condensation module; the steam generating module consists of a steam generating device 1 and its sequential The connected flow sensor 3, the first solenoid valve 4 and the first one-way valve 5 are composed. The flow sensor 3 in the module can display the flow of steam flowing out of the superheated steam generating device in real time. The first one-way valve 5 can prevent the steam from flowing back into the superheated steam generator 1 through the pipeline 2 .

[0025] The gas storage module is composed of a gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com