Method for extracting herbaceous plants for external use by virtue of small-molecular cutting technology

A technology of herbal plants and cutting technology, which is applied in the field of extracting herbal plants with small molecule cutting technology, which can solve the problems of underutilization and incomplete extraction of medicinal ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

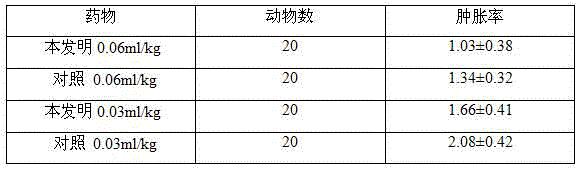

Image

Examples

Embodiment 1

[0026] (1) Take 500g of Forsythia forsythia removed from mildew and impurities, crush it and dissolve it in 2500mL of acetone, filter the slurry to recover the filtrate.

[0027] (2) The solvent and the solute in the recovered filtrate are separated, and the separated solute is subjected to ultrafine pulverization treatment using an ultrafine pulverizer. Ultrafine pulverization: Forsythia is pulverized three times in a superfine pulverizer, passed through a 100-mesh sieve, and then pulverized twice, passed through a 200-mesh sieve, and pulverized for 10 minutes each time.

[0028] (3) Use the dry method to break the cell wall of the solute after ultrafine pulverization;

[0029] (4) Put 250g of the solute and 100ml of entrainer ethanol into the extraction kettle of the supercritical fluid extraction apparatus after the wall breaking treatment. The flow rate of the supercritical fluid entering the extraction kettle is 30L / h. The temperature of the extraction kettle is 40°C and ...

Embodiment 2

[0034] (1) Take 500g of pinellia that removes mildew and impurities, crush it and dissolve it in 3000mL of ethyl acetate, filter the slurry to recover the filtrate.

[0035] (2) The solvent and the solute in the recovered filtrate are separated, and the separated solute is subjected to ultrafine pulverization treatment using an ultrafine pulverizer. Superfine pulverization Pinellia was pulverized three times in a superfine pulverizer, passed through a 100-mesh sieve, and then pulverized twice, crossed a 200-mesh sieve, and pulverized for 10 minutes each time.

[0036] (3) Use the dry method to break the cell wall of the solute after ultrafine pulverization;

[0037] (4) Put 250g of solute and 120ml of entrainer propylene glycol into the extraction kettle of the supercritical fluid extraction apparatus after the wall-breaking treatment. The flow rate of the supercritical fluid entering the extraction kettle is 40L / h. 32MPa, the extraction time with carbon dioxide supercritical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com