Branched boric acid functionalized monolithic column and preparation method and application thereof

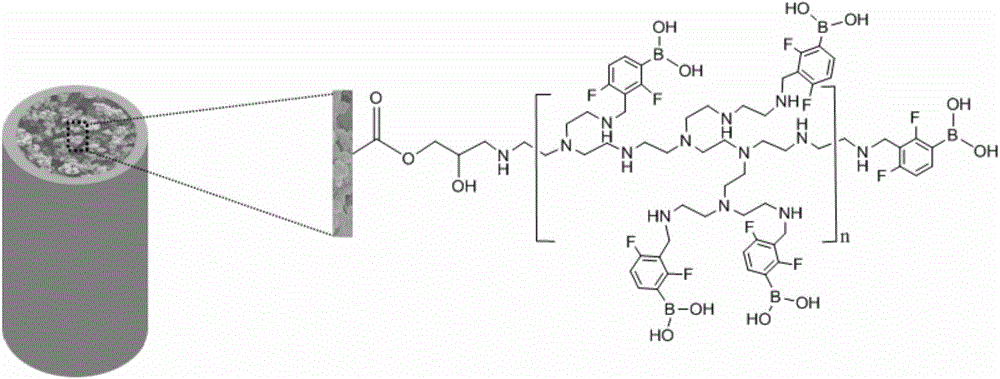

A monolithic column and dendritic technology, applied in the field of functionalized material devices, can solve the problems of inability to use and the binding force does not reach the antibody level, and achieve the effect of improving binding force, strong anti-interference ability and increasing binding capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

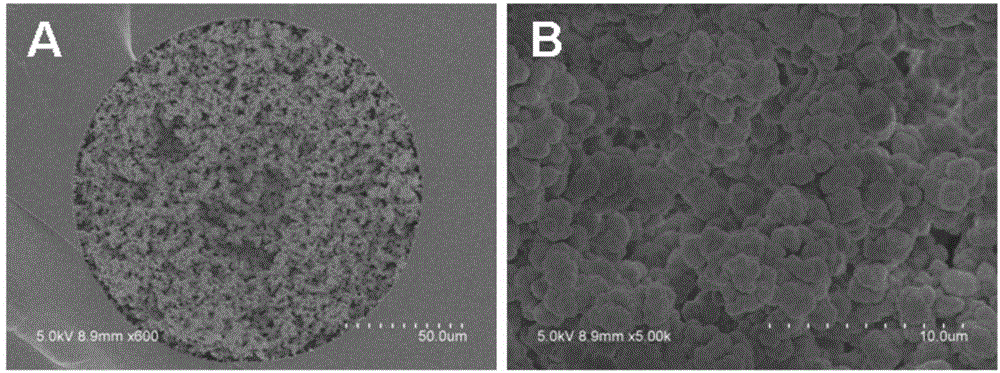

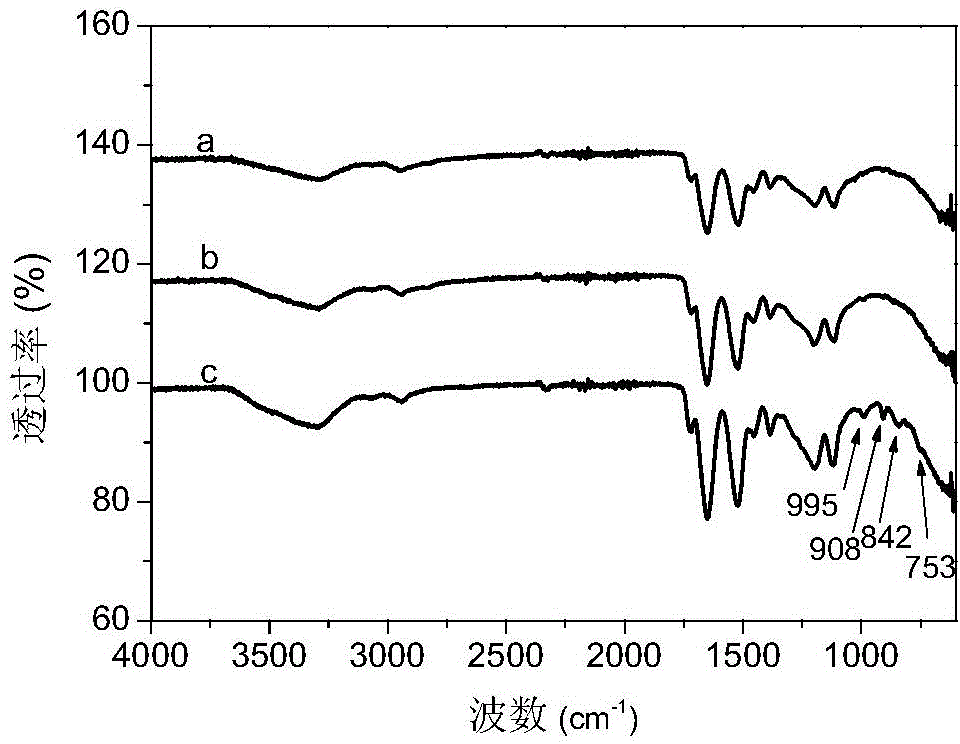

[0074] Example 1: Preparation of epoxy-functionalized monolithic column 1

[0075] The epoxy-based functionalized monolithic column is selected as the basic monolithic column. The epoxy-functionalized monolithic column was synthesized by thermally induced free radical polymerization. Before preparing the monolithic column, the capillary was successively treated with acid, alkali activation and γ-MAPS derivatization, and then 30 mg of monomer glycidyl methacrylate (GMA) containing epoxy functional groups, crosslinking agent N, N′ - Methylenebisacrylamide (MBAA) 60mg, porogen 174mg lauryl alcohol and dimethyl sulfoxide 200mg total 374mg mixed with initiator azobisisobutyronitrile (AIBN) 1mg, vortexed for 5 minutes, and then ultrasonicated for 30 Minutes to obtain a uniform pre-polymerization solution. Fill it into a double bond-modified capillary, and put it into a 75°C water bath for 12 hours of reaction. After the polymerization reaction is completed, unreacted substances a...

Embodiment 2

[0076] Example 2: Preparation of epoxy-functionalized monolithic column 2

[0077] The epoxy-based functionalized monolithic column is selected as the basic monolithic column. The epoxy-functionalized monolithic column was synthesized by thermally induced free radical polymerization. Before preparing the monolithic column, the capillary was successively treated with acid, alkali activation and γ-MAPS derivatization, and then 25 mg of monomer glycidyl methacrylate (GMA) containing epoxy functional groups, crosslinking agent N, N′ - Methylenebisacrylamide (MBAA) 55mg, porogen 160mg lauryl alcohol and dimethyl sulfoxide 200mg total 360mg were mixed with initiator azobisisobutyronitrile (AIBN) 1mg, vortexed for 4 minutes, and then ultrasonicated for 25 Minutes to obtain a uniform pre-polymerization solution. Fill it into a double bond-modified capillary, and then put it in a 70°C water bath for 11 hours of reaction. After the polymerization reaction is completed, unreacted subs...

Embodiment 3

[0078] Example 3: Preparation of epoxy-functionalized monolithic column 3

[0079] The epoxy-based functionalized monolithic column is selected as the basic monolithic column. The epoxy-functionalized monolithic column was synthesized by thermally induced free radical polymerization. Before preparing the monolithic column, the capillary was successively treated with acid, alkali activation and γ-MAPS derivatization, and then 35 mg of monomer glycidyl methacrylate (GMA) containing epoxy functional groups, crosslinking agent N, N′ - Methylenebisacrylamide (MBAA) 65mg, porogen 180mg lauryl alcohol and dimethyl sulfoxide 200mg total 380mg were mixed with initiator azobisisobutyronitrile (AIBN) 1mg, vortexed for 6 minutes, and then ultrasonicated for 35 Minutes to obtain a uniform pre-polymerization solution. Fill it into a double bond-modified capillary, and then place it in a water bath at 80°C for 13 hours to react. After the polymerization reaction is completed, unreacted su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dissociation constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com