Catalyst for hydrogenating and purifying crude 2,6-naphthalic acid and preparation method of catalyst

A kind of naphthalene dicarboxylic acid and catalyst technology, applied in the catalyst for the hydrogenation purification of crude 2,6-naphthalenedicarboxylic acid and the field of preparation thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

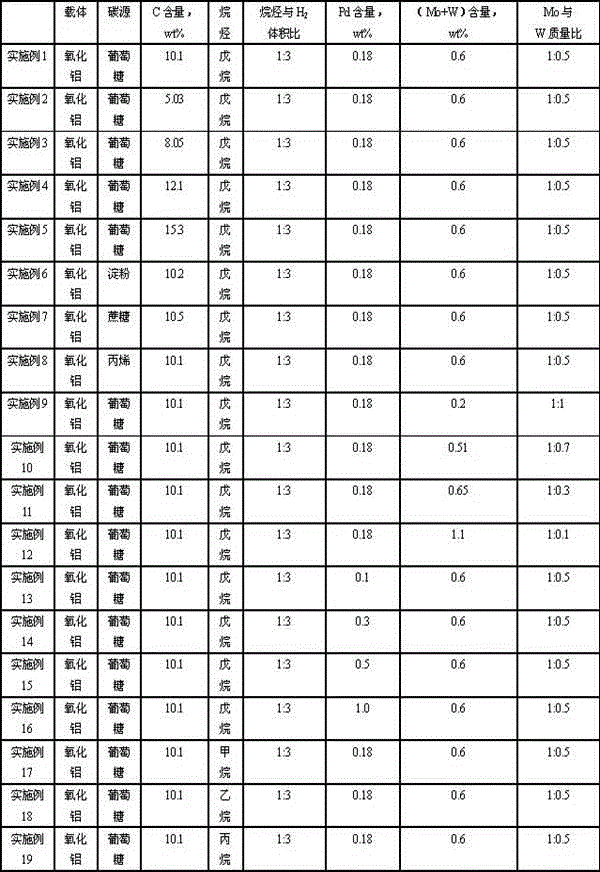

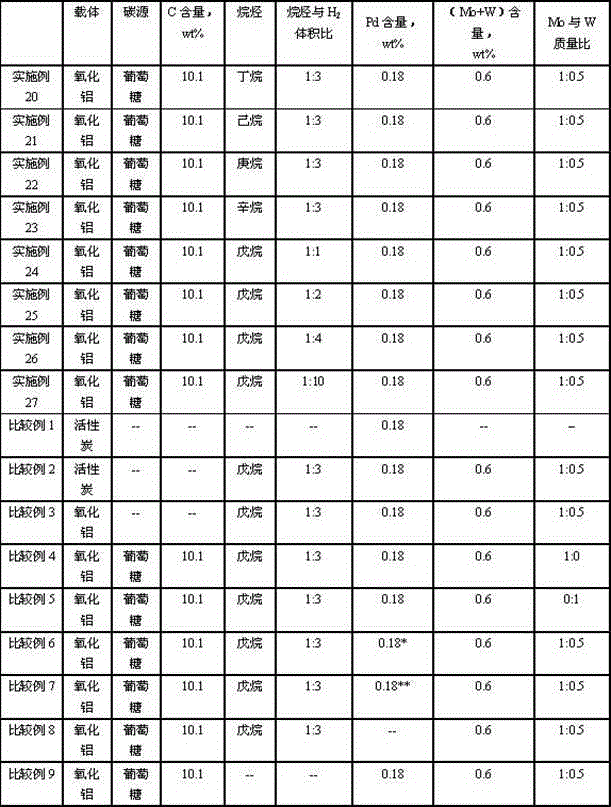

Embodiment 1

[0020] Preparation of carrier: take 500gAl 2 o 3 , and then follow the glucose and Al 2 o 3 The mass ratio is 0.65:1 to prepare 1000ml glucose aqueous solution, and 500gAl 2 o 3 Add it and soak for 12h. After impregnation, it was dried in a vacuum oven at 90°C for 3h, and then calcined at 500°C for 3h under the protection of nitrogen atmosphere to obtain a carrier whose carbon content was determined to be 10.1wt% by a carbon-sulfur analyzer.

[0021] Catalyst preparation: (NH 4 ) 6 Mo 7 o 24 and (NH 4 ) 6 h 2 W 12 o 40 Dissolve in water to obtain 100 ml of impregnating liquid, the content of Mo in the impregnating liquid is 0.42 g, the mass ratio of Mo to W is 1:0.5, mix the obtained impregnating liquid with 100 g of carrier, let stand for 12 h, and dry at 90°C for 3 h, Precursor I was obtained by roasting at 500°C for 3 hours in a muffle furnace; V (C 5 h 12 ) / V (H 2 )=1:3 in a mixed atmosphere at 700°C for 2h, then lower the temperature to obtain the prec...

Embodiment 2-5

[0025] Preparation of carrier: take 500gAl 2 o 3 , and then follow the glucose and Al 2o 3 The mass ratios are 0.25:1, 0.5:1, 0.75:1, and 1:1 to prepare 1000ml glucose aqueous solution, and 500gAl 2 o 3 Add it and soak for 12h. After impregnation, dry in a vacuum oven at 90°C for 3h, and then bake at 500°C for 3h under the protection of nitrogen atmosphere to obtain the carrier. The carbon content is 5.03wt%, 8.05wt%, 12.1wt% and 15.3wt%. All the other operations are the same as in Example 1. For convenience of comparison, the key experimental conditions used in Examples 2-5 and the obtained catalyst composition are listed in Table 2 and the catalyst evaluation results are listed in Table 3.

Embodiment 6

[0027] Preparation of carrier: take 500gAl 2 o 3 , and then follow the starch and Al 2 o 3 The mass ratio of each is 0.65:1 to prepare 1000ml starch aqueous solution, and 500gAl 2 o 3 Add it and soak for 12h. After impregnation, dry in a vacuum oven at 90°C for 3h, and then bake at 500°C for 3h under the protection of nitrogen atmosphere to obtain a carrier whose carbon content is 10.2wt%. All the other operations are the same as in Example 1. For convenience of comparison, the key experimental conditions used in Example 6 and the obtained catalyst composition are listed in Table 2 and the catalyst evaluation results are listed in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com