Preparation method of catalyst for synthesizing vinyl acetate by virtue of acetylene method and synthetic method of vinyl acetate

A technology of vinyl acetate and synthesis method, applied in the preparation of organic compounds, preparation of carboxylate, chemical instruments and methods, etc., can solve problems such as low catalyst activity, and achieve the effect of improving space-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

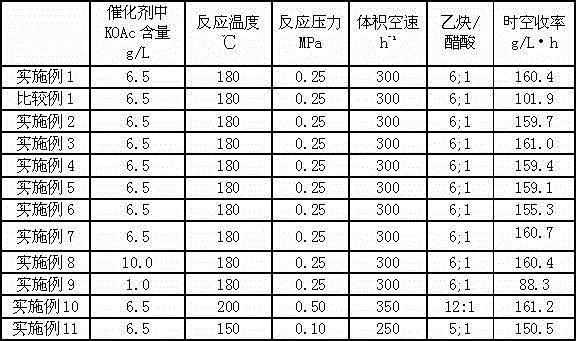

Examples

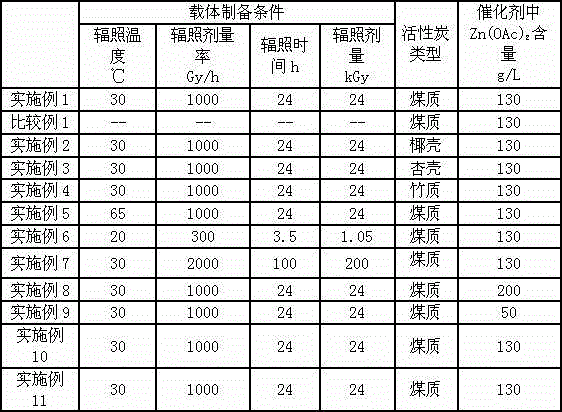

Embodiment 1

[0020] 1. Catalyst preparation method

[0021] (A) Carrier preparation: measure 1L with a diameter of 3 mm, a length of 2 cm, and a pore volume of 0.8 cm 3 / g, the specific surface area is 1200 cm 2 / g of coal cylindrical activated carbon is placed in the ALLANCE series of γ-ray radiation device, under the condition of 30 ℃, 1000Gy / h 60 Co-γ rays are irradiated for 24 hours to obtain the carrier.

[0022] (B) Impregnation: impregnate the above-mentioned 1L carrier with 630ml impregnation solution. Of which Zn in the dipping solution (OAc) 2 The content is 130 g, the potassium acetate content is 6.5 g, and the solvent in the impregnation solution is a mixed solvent of acetic acid and water (70 wt% of acetic acid and 30 wt% of water in weight percentage).

[0023] (C) Drying: drying at 100°C to obtain the catalyst.

[0024] 2. Catalyst evaluation

[0025] The catalyst synthesized by the above method was evaluated in a laboratory microreactor. The evaluation conditions are: catalyst load...

Embodiment 2

[0036] 1. Catalyst preparation method

[0037] (A) Carrier preparation: measure 1L with a diameter of 3 mm, a length of 2 cm, and a pore volume of 0.8 cm 3 / g, the specific surface area is 1200 cm 2 / g coconut shell-shaped cylindrical activated carbon is placed in the ALLANCE series γ-ray radiation device, at 30 ℃, 1000Gy / h 60 Co-γ rays are irradiated for 24 hours to obtain the carrier.

[0038] (B) Impregnation: impregnate the above-mentioned 1L carrier with 630ml impregnation solution. Of which Zn in the dipping solution (OAc) 2 The content is 130 g, the potassium acetate content is 6.5 g, and the solvent in the impregnation solution is a mixed solvent of acetic acid and water (70 wt% of acetic acid and 30 wt% of water in weight percentage).

[0039] (C) Drying: drying at 100°C to obtain the catalyst.

[0040] 2. Catalyst evaluation

[0041] The catalyst synthesized by the above method was evaluated in a laboratory microreactor. The evaluation conditions are: catalyst loading: 30ml ...

Embodiment 3

[0044] 1. Catalyst preparation method

[0045] (A) Carrier preparation: measure 1L with a diameter of 3 mm, a length of 2 cm, and a pore volume of 0.8 cm 3 / g, the specific surface area is 1200 cm 2 / g of apricot shell cylindrical activated carbon is placed in the ALLANCE series of γ-ray radiation device, at 30 ℃, 1000Gy / h 60 Co-γ rays are irradiated for 24 hours to obtain the carrier.

[0046] (B) Impregnation: impregnate the above-mentioned 1L carrier with 630ml impregnation solution. Of which Zn in the dipping solution (OAc) 2 The content is 130 g, the potassium acetate content is 6.5 g, and the solvent in the impregnation solution is a mixed solvent of acetic acid and water (70 wt% of acetic acid and 30 wt% of water in weight percentage).

[0047] (C) Drying: drying at 100°C to obtain the catalyst.

[0048] 2. Catalyst evaluation

[0049] The catalyst synthesized by the above method was evaluated in a laboratory micro-reactor. The evaluation conditions are: catalyst loading: 30ml ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Space-time yield | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Space-time yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com