Device and method for preparing magnesium alloy ingot for deformation

A preparation device and magnesium alloy technology, applied in metal processing equipment, equipment for feeding molten metal into molds, manufacturing tools, etc., can solve the problem of oxidative combustion of magnesium alloy melt, affecting the yield of ingot billets, and the temperature of catheter tubes Control difficulties and other problems to achieve the effect of avoiding disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

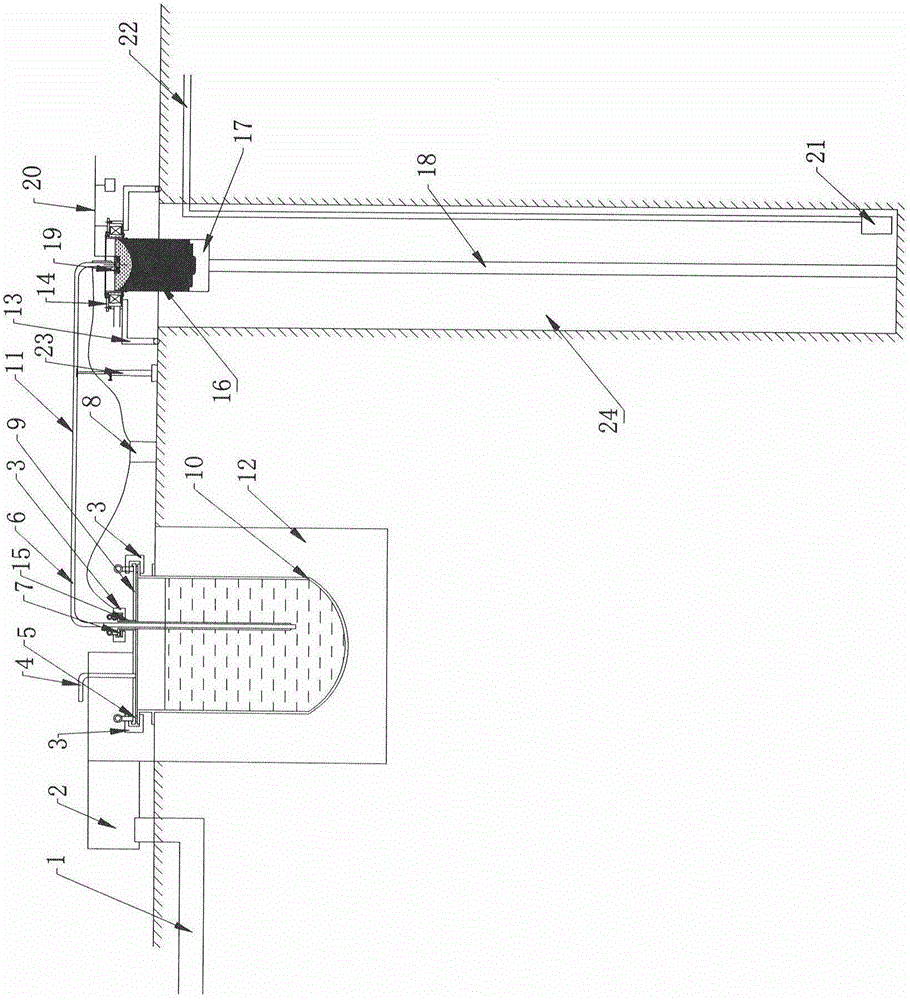

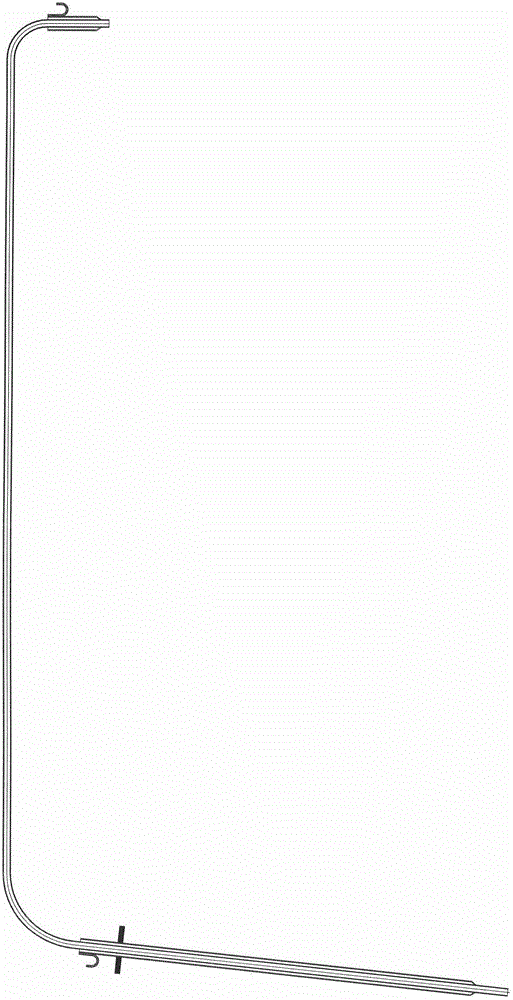

[0044] Weigh 1000kg of raw materials according to the composition ratio of AZ31B magnesium alloy, put the weighed raw materials into the crucible 10 preheated to 300°C and raise the temperature, control the temperature at 740°C, and carry out stirring and refining for 30 minutes after all the raw materials are melted. Dust removal device 2, after the melt temperature reaches 720°C after refining, put a sealing ring 5 on the upper edge of the crucible 10 and cover the furnace cover 9, and clamp the furnace cover 9 and the crucible 10 with a sealing fastening fixture 3; put the sealing ring Put it on the furnace cover 9 to reserve the insertion hole 15 where the catheter 6 is to be inserted, and then use the heat pipe rapid heating device 8 to preheat the heat pipe to 730°C. hole, and at the same time put the other end of the catheter 6 into the mold, and use the catheter height adjustment device 23 to adjust the position of the catheter 6 in the mold, and then use the sealing cl...

Embodiment 2

[0047] Weigh 1000kg of raw materials according to the composition ratio of Mg-10Gd-3Y-2Zn-0.6Zr magnesium alloy, put the weighed raw materials into the crucible 10 preheated to 500°C and raise the temperature, control the temperature at 780°C, and wait until all the raw materials are melted Then carry out stirring and refining for 40 minutes. During refining, the dust removal device 2 is turned on. After the melt temperature reaches 780°C after refining, put a sealing ring 5 on the upper edge of the crucible 10 and cover the furnace cover 9, and seal the furnace cover 9 with a sealing fixture 3. Clamp with the crucible 10; place the sealing ring on the furnace cover 9 to reserve the insertion hole 15 where the catheter 6 is located, and then use the heat pipe rapid heating device 8 to preheat the heat pipe to 760°C at one end of the pipe Insert it from the reserved insertion hole on the furnace cover, put the other end of the catheter 6 into the mold, and adjust the position of...

Embodiment 3

[0050] Weigh 2000kg of raw materials according to the composition ratio of ZK60 magnesium alloy, put the weighed raw materials into the crucible 10 preheated to 400°C and heat up, the temperature is controlled at 760°C, after all the raw materials are melted, stir and refine for 50 minutes, and turn on when refining Dust removal device 2, after the melt temperature reaches 760°C after refining, put a sealing ring 5 on the upper edge of the crucible 10 and cover the furnace cover 9, and clamp the furnace cover 9 and the crucible 10 with a sealing fastening fixture 3; put the sealing ring 5. Place it on the furnace cover 9 to reserve the insertion hole 15 where the catheter 6 is inserted, and then use the heat pipe rapid heating device 8 to preheat the heat pipe to 740°C. One end of the catheter 6 is preheated from the furnace cover 9 Insert the remaining insertion hole 15 into the mold, and at the same time put the other end of the catheter tube 6 into the mold, and adjust the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com