Furfuryl alcohol modified solution for modifying wood materials or bamboo materials

A modification and furfuryl alcohol technology, which is applied in the field of wood or bamboo processing and preservation, can solve the problems of inability to deeply modify wood, large consumption of furfuryl alcohol, unfavorable solution preservation, etc., to achieve improved dimensional stability, simple process, and improved mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

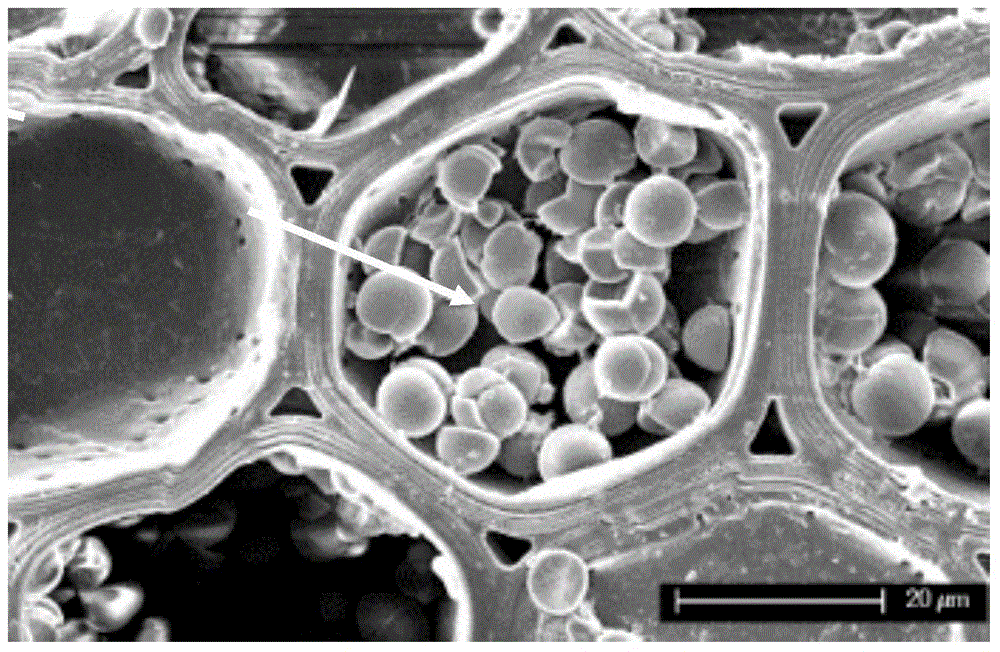

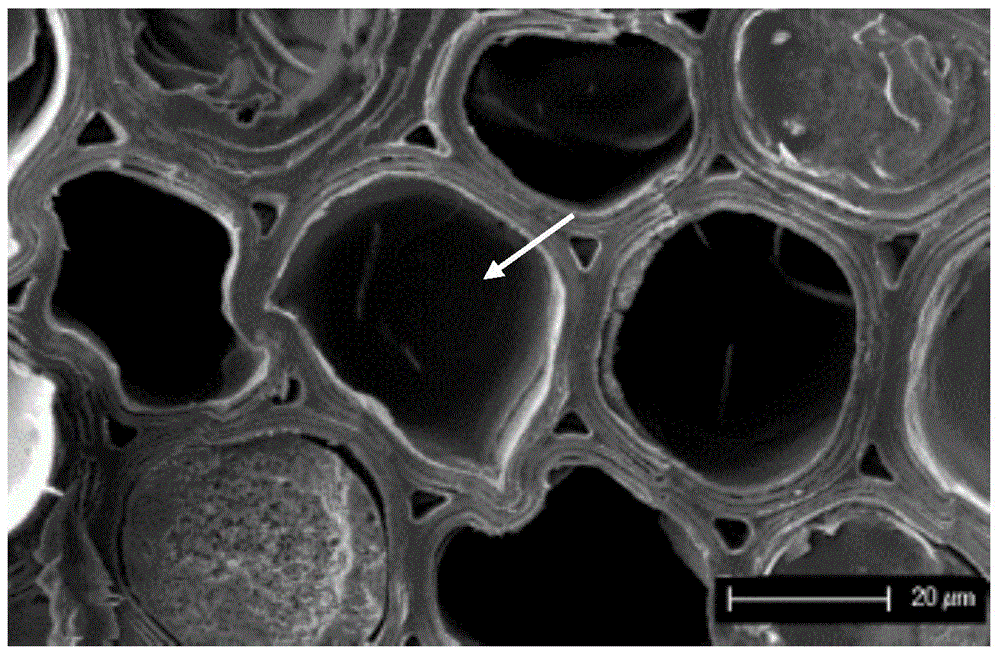

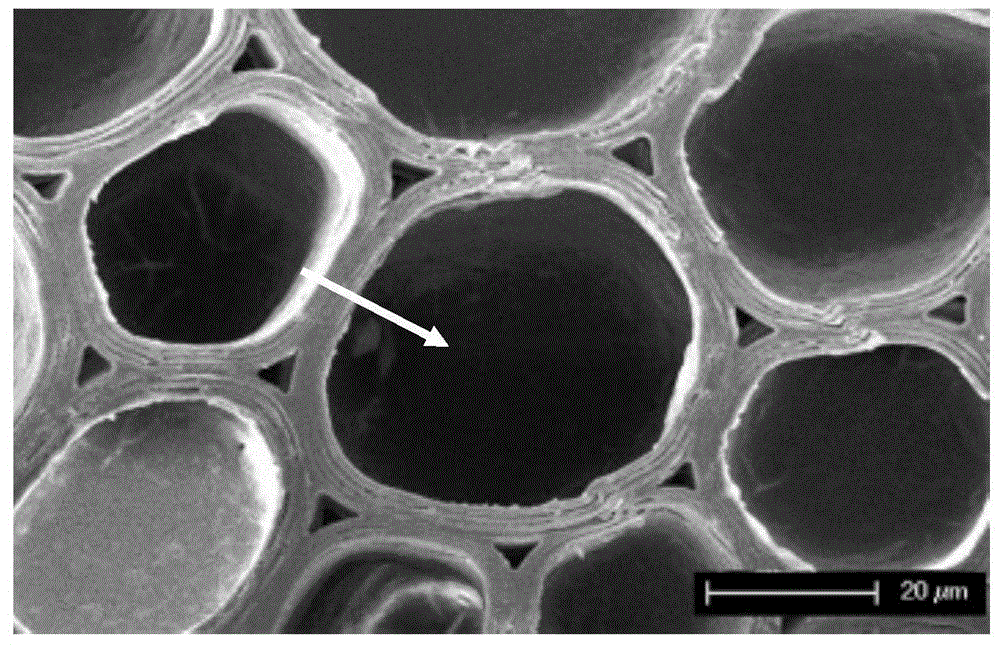

Image

Examples

Embodiment 1

[0031] Specific steps: at room temperature 22-25℃,

[0032] With compound organic acid as catalyst: furfuryl alcohol 50%, citric acid 1.15%, oxalic acid 0.6%, borax 2% (Na 2 B 4 O 7 ·10H 2 O), the balance is water. Dissolve citric acid and borax in water, add furfuryl alcohol, stir evenly with a magnetic stirrer, finally add oxalic acid, continue stirring until the solid is completely dissolved, and obtain a uniform, light yellow clear solution; pH 3.90.

Embodiment 2

[0034] Take maleic anhydride as a catalyst: furfuryl alcohol 50%, maleic anhydride 1.75%, borax 2%, and the balance is water. Dissolve maleic anhydride and borax in water, add furfuryl alcohol, and stir evenly with a magnetic stirrer to obtain a uniform, light yellow clear solution. The pH value is 4.01.

Embodiment 3

[0036] At room temperature 22-25℃, with salicylic acid as catalyst: furfuryl alcohol 50%, salicylic acid 1.75%, borax 2% (Na 2 B 4 O 7 ·10H 2 O), the balance is water. Dissolve salicylic acid and borax in water, add furfuryl alcohol, and stir evenly with a magnetic stirrer to obtain a uniform, light yellow clear solution; the pH value is 3.40.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com