A kind of preparation method of forest camouflage knitted wader material

A technology of camouflage knitting and camouflage needles, which is applied in the field of preparation of forest camouflage knitted wader materials, can solve the problems of single color and low grade, and achieve the effect of bright surface, beautiful appearance and single color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

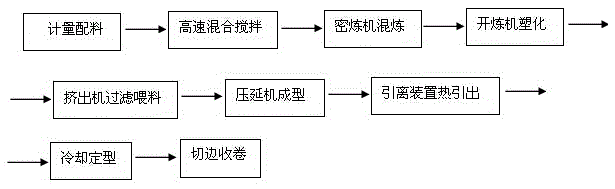

[0033] Calendering of PVC transparent embryo film: metering and batching→high-speed mixing→mixing→plasticization of the mill→extruder filtration→calendering→leading→cooling and setting→coiling; the process parameters of the calendering process are: high-speed mixing time is : 350~450S; Gap between rolls and rolls of kneading machine: 4~5mm, temperature difference between front and rear rolls 10℃, roller control temperature 160~170℃; extruder temperature 130~160℃, filter screen 100~150 mesh; lead-off temperature 140~160℃, speed ratio 1.1~2.5; cooling time 1~2min;

[0034] Paste treatment of camouflage knitted fabric: batching→mixing→pasting→drying→cooling→coiling; the process parameters of the pasting treatment are: stirring time 15-30min, paste viscosity 200-500cps; A scraper is installed on the side of the silk mesh wheel, and the amount of paste is controlled by adjusting the scraper; drying at 100-120°C for 1-2 minutes; cooling time 10-30S.

[0035] High temperature bondin...

Embodiment 2

[0038] Calendering of PVC transparent embryo film: metering and batching→high-speed mixing→mixing→plasticization of the mill→extruder filtration→calendering→leading→cooling and setting→coiling; the process parameters of the calendering process are: high-speed mixing time is : 435S; the gap between the rollers of the open mill: 4.5mm, the temperature difference between the front and rear rollers is 10°C, the roller control temperature is 160°C; the extruder temperature is 145°C, the filter screen is 125 mesh; the lead-off temperature is 150°C, the speed ratio is 1.5; cooling time 2min;

[0039] Paste treatment of camouflage knitted fabric: batching→mixing→pasting→drying→cooling→coiling; the process parameters of the pasting treatment are: stirring time 25min, paste viscosity 300cps; Install the scraper on the side, and control the amount of paste by adjusting the scraper; dry at 110°C for 1 minute; cool down for 15S.

[0040] High temperature bonding: heat or preheat the PVC t...

Embodiment 3

[0043] Calendering of PVC transparent embryo film: metering and batching→high-speed mixing→mixing→plasticization of the mill→extruder filtration→calendering→leading→cooling and setting→coiling; the process parameters of the calendering process are: high-speed mixing time is : 450S; the gap between the rollers of the training machine: 5mm, the temperature difference between the front and rear rollers is 10°C, the roller control temperature is 170°C; the extruder temperature is 155°C, the filter screen is 12150 mesh; the lead-off temperature is 160°C, the speed ratio is 2.1; the cooling time is 2min ;

[0044] Paste treatment of camouflage knitted fabric: batching→mixing→pasting→drying→cooling→coiling; the process parameters of the pasting treatment are: stirring time 3min, paste viscosity 500cps; Install the scraper on the side, and control the amount of paste by adjusting the scraper; dry at 120°C for 1 minute; cool down for 25S.

[0045] High temperature bonding: heat or pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com