A microwave-heatable instant food cup cover and its manufacturing process

A technology of convenience food and microwave heating, which is applied in the direction of layered products, flexible coverings, chemical instruments and methods, etc., can solve the problems of black shadows on the printed product layout, poor ink absorption ability, and great difficulty, so as to ensure sealing and Moisture-proof performance, reduction of manufacturing cost, effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

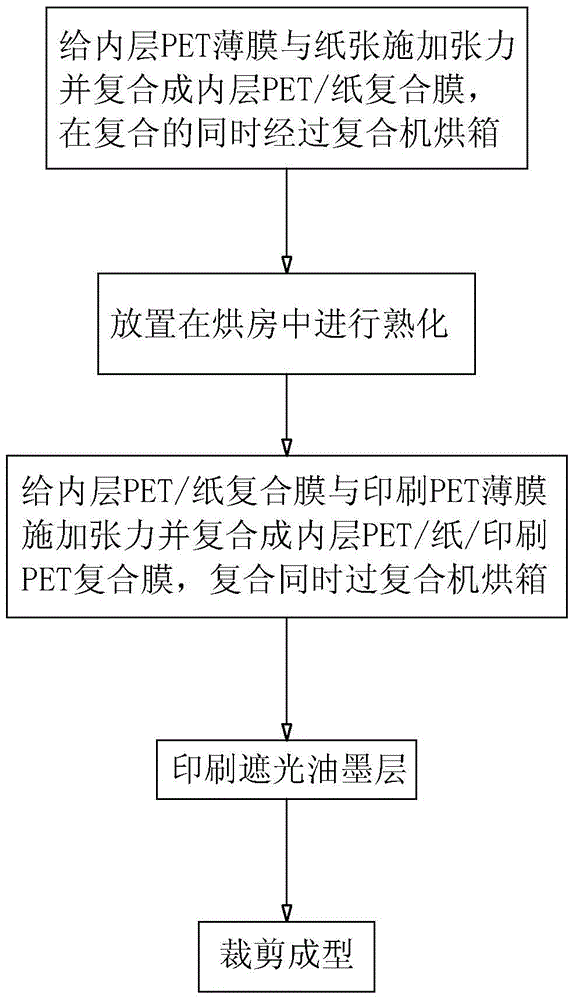

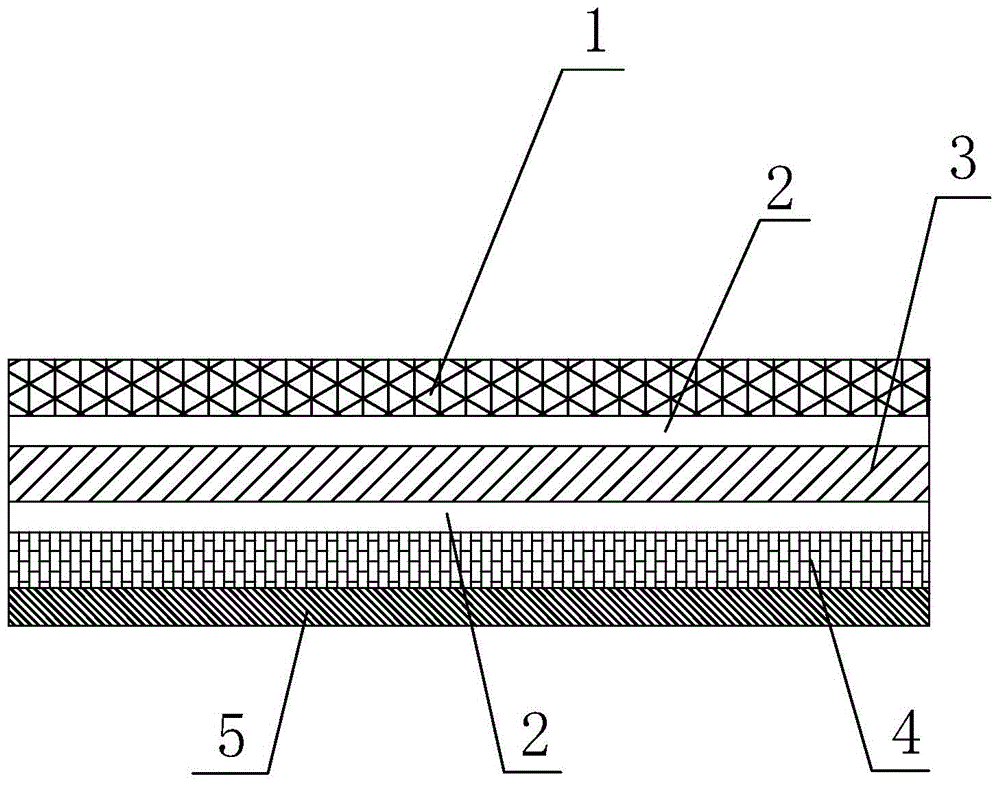

[0028] A microwave-heatable instant food cup lid and its manufacturing process. The cup lid includes printed PET film 1, paper 3, and inner PET film 4. By controlling the tension difference between the materials of each layer, each Layer materials are compounded so that the cup lid without aluminum foil layer can meet the same flatness requirements as the traditional cup lid with aluminum foil layer. The specific steps are as follows:

[0029] a. Apply a tension of 80N to the inner PET film, and a tension of 105N to the paper, and compound the tension-applied inner PET film and the tension-applied paper on a dry laminating machine with an adhesive to form a semi-finished composite film , while compounding, it passes through the compound machine oven for the first time. The temperature set in the compound machine oven is 55°C to volatilize the residual adhesive from the semi-finished compound film to prevent the adhesive from contacting the food and ensure that the lid reaches t...

Embodiment 2

[0037] A microwave-heatable instant food cup lid and its manufacturing process. The cup lid includes printed PET film 1, paper 3, and inner PET film 4. By controlling the tension difference between the materials of each layer, each Layer materials are compounded so that the cup lid without aluminum foil layer can meet the same flatness requirements as the traditional cup lid with aluminum foil layer. The specific steps are as follows:

[0038]a. Apply a tension of 110N to the inner PET film, apply a tension of 130N to the paper, and compound the tensioned inner PET film and the tensioned paper on a dry laminating machine with an adhesive to form a semi-finished composite film , while compounding, it passes through the compound machine oven for the first time. The temperature set in the compound machine oven is 65°C to volatilize the residual adhesive from the semi-finished compound film to prevent the adhesive from contacting the food and ensure that the lid reaches the food. ...

Embodiment 3

[0046] A microwave-heatable instant food cup lid and its manufacturing process. The cup lid includes printed PET film 1, paper 3, and inner PET film 4. By controlling the tension difference between the materials of each layer, each Layer materials are compounded so that the cup lid without aluminum foil layer can meet the same flatness requirements as the traditional cup lid with aluminum foil layer. The specific steps are as follows:

[0047] a. Apply a tension of 95N to the inner layer of PET film, apply a tension of 118N to the paper, and use an adhesive to compound the tensioned inner layer of PET film and the tensioned paper on a dry laminating machine to form a semi-finished composite film , while compounding, it passes through the compound machine oven for the first time. The temperature set in the compound machine oven is 60°C to volatilize the residual adhesive from the semi-finished compound film, prevent the adhesive from contacting the food, and ensure that the lid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com