Straddle type single track working vehicle bogie

A straddle-type monorail and work vehicle technology, which is applied to the bogie, the device for lateral relative movement between the chassis and the bogie, and the components of the railway car body, etc., which can solve the problems of high cost, heavy, and many curves on the single track , to achieve the effect of safe operation, strong climbing ability and small turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

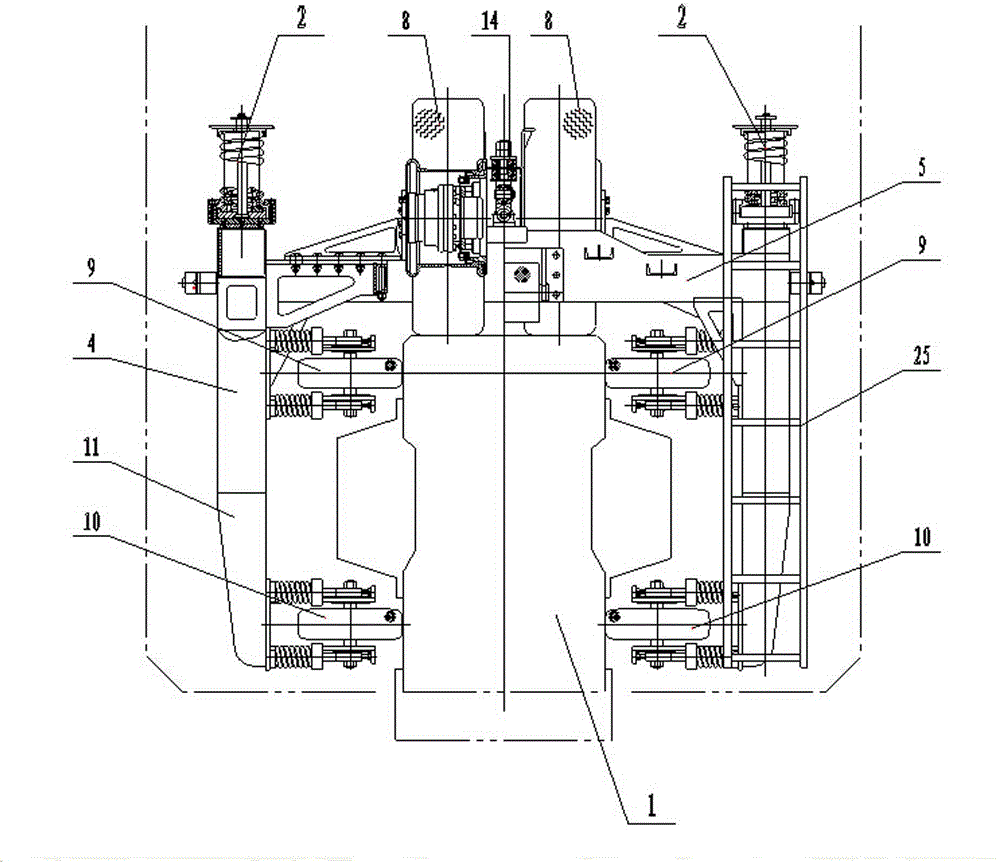

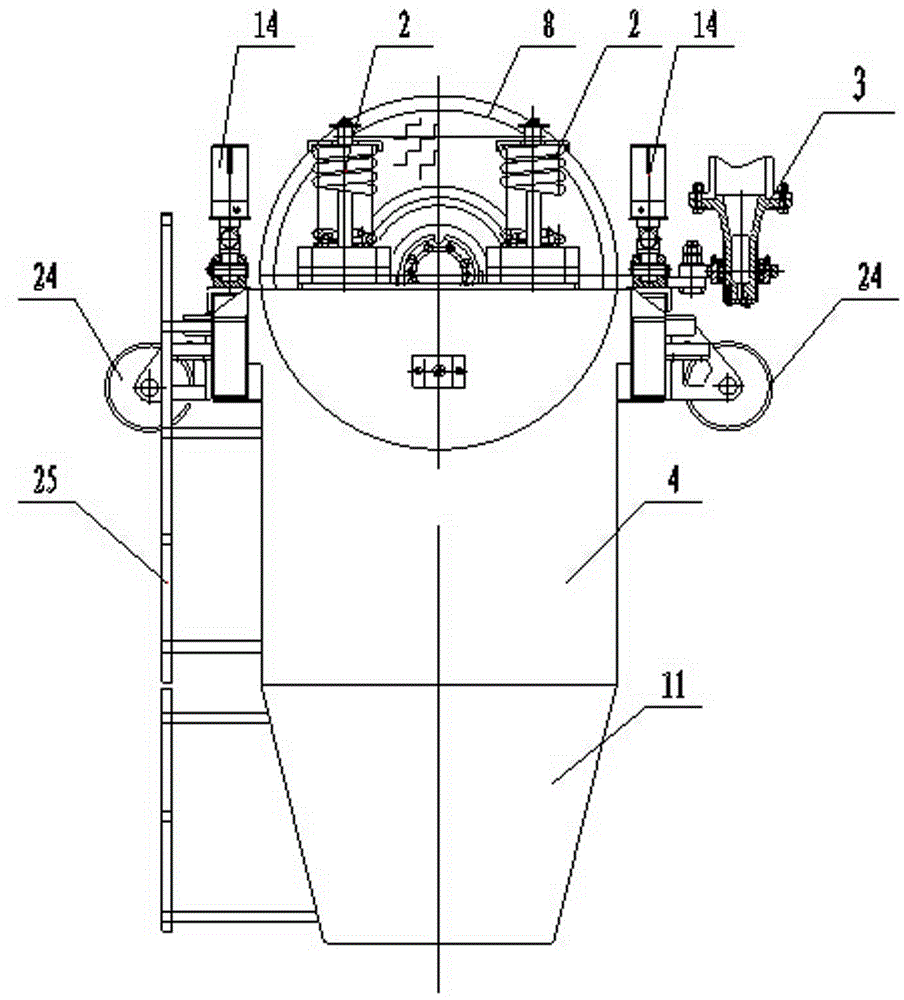

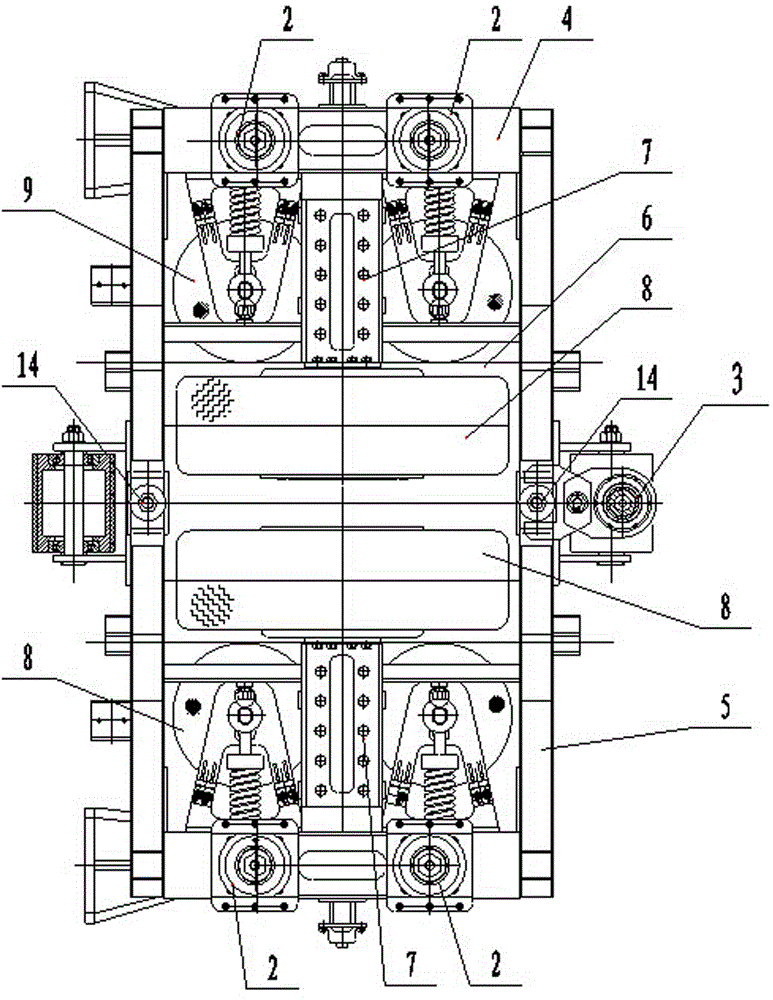

[0030] A straddle-type monorail operating vehicle bogie, such as figure 1 , 2 , 3, including the frame straddling the PC beam 1, the secondary suspension device 2, and the traction device 3, such as Figure 4 , 5 , 6, the frame as a whole is a "Π"-shaped all-steel welded plate box structure, the material is Q345B, with sufficient strength and rigidity, including the side beams located on both sides of the PC beam track, and the two sides connected to the upper part of the side beams. The end beams 5 between the ends and the two longitudinal beams 6 connected between the end beams, the motor brackets 7 are respectively fixed between the upper part of the side beams and the corresponding longitudinal beams, and also include the rescue wheel mounting seat, the secondary steel round spring seat Plate, limit device seat, etc.; two independently driven running wheel assemblies 8 are installed on the two motor brackets, four guide wheel assemblies 9 are installed on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com