Equipment and process for producing graphene by spray drying and microwaves

A graphene and microwave technology, applied in the field of graphene new material preparation, can solve the problems of cumbersome process of drying graphite oxide, high energy consumption, difficult to collect, etc., and achieves the effects of convenient operation, improved product yield, and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

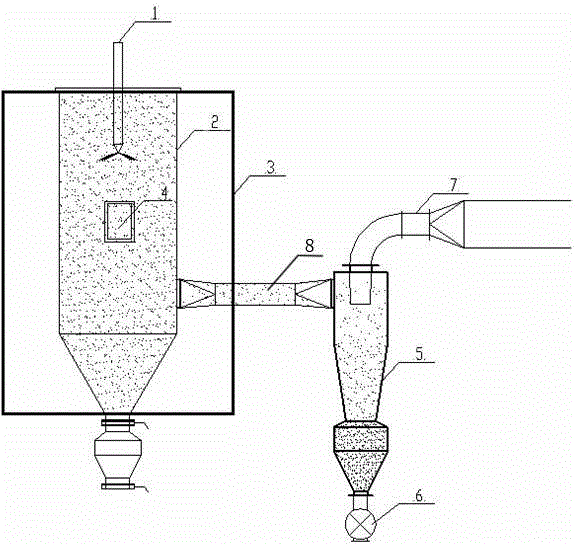

[0016] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

[0017] As shown in the figure, a device for producing graphene by spray drying and microwave, including atomizer 1, drying chamber 2, microwave cavity 3, observation port 4, cyclone collector 5, wind-closing unloader 6 and exhaust Tube 7. The atomizer 1 is installed on the top of the inner cavity of the drying chamber 2, and the bottom of the drying chamber 2 is connected to the head of the cyclone collector 5 through a connecting pipe 8; the drying chamber 2 is arranged in the microwave cavity 3, and the A plurality of microwave emitters are arranged on two opposite inner walls in the microwave cavity 3, the microwave cavity 3 and the connecting pipe 8 are made of stainless steel and lined with polytetrafluoroethylene, the atomizer 1 and the drying The material of the chamber 2 is quartz, corundum or ceramics; the top of the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com