Underground sewage closed-loop purification method

A closed-circuit purification, underground mine technology, applied in chemical instruments and methods, mining wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problem of high system operating costs and equipment maintenance costs, high drainage costs and sewage costs, Due to the large investment of human, material and financial resources, the effect of shortening the time of sewage purification, reducing the cost of water source and protecting the natural balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

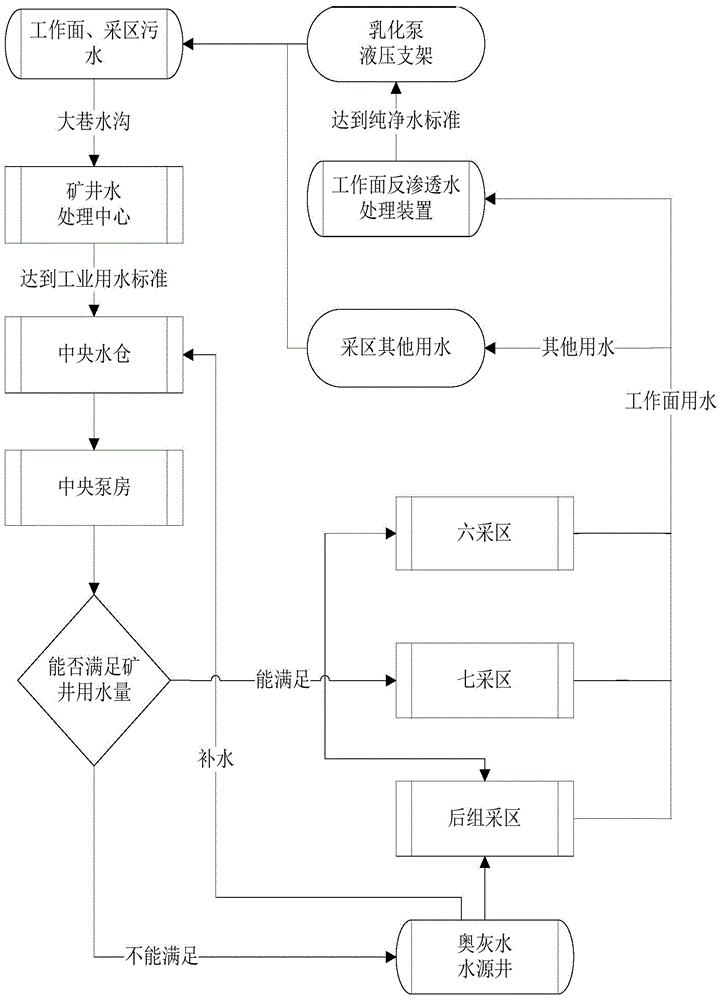

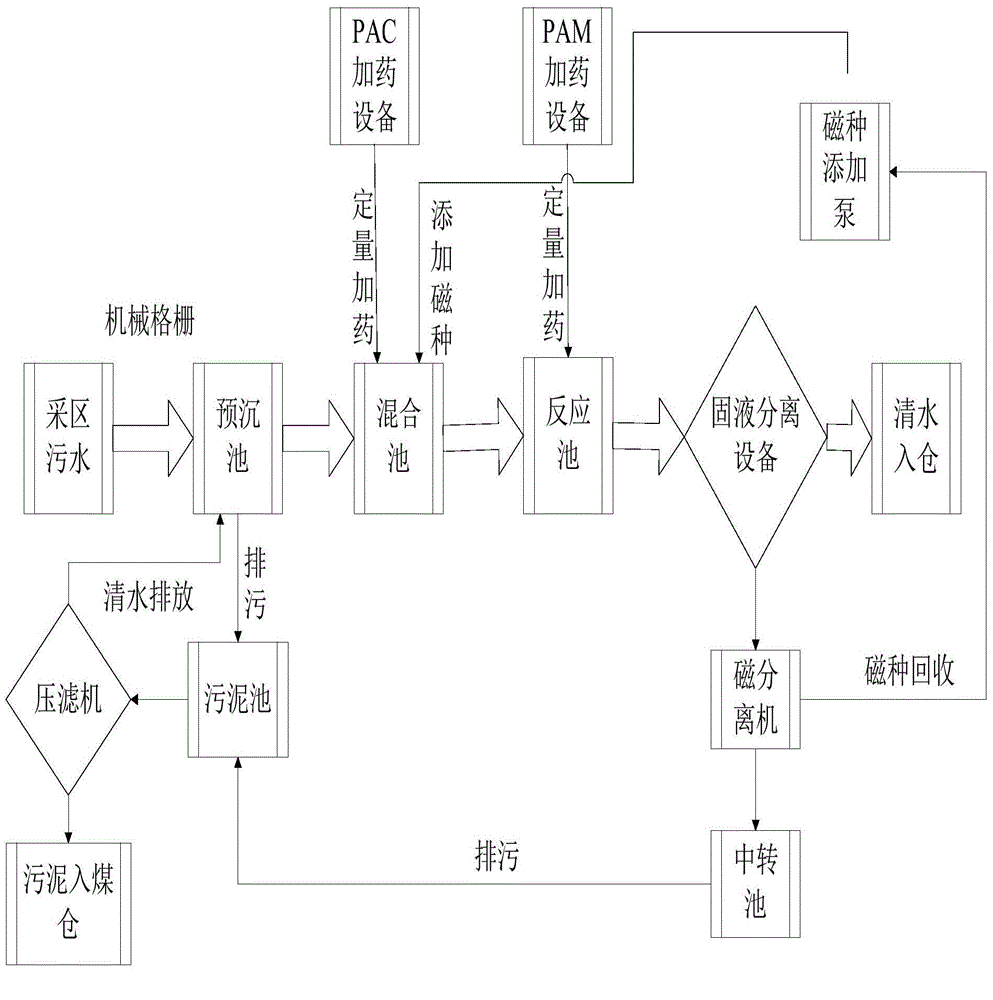

[0022] Such as figure 1 In the closed-circuit purification method for sewage under the mine shown, the industrial water stored in the central water tank is transported to the pipeline through the central pump room and then transported to the mining area through the pipeline, and the central pump room is used for the water in the mining area According to the comparison result, choose whether to replenish the water. When the water replenishment is not required, the central pump house will directly supply water to the mining area; The water source well supplies water to the central pump house and the production area respectively, and the production area uses the industrial water to form water for the working face, wherein a part of the water for the working face is treated by the reverse osmosis water treatment device of the working face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com