Pleurotus eryngii culture medium and industrial culture method

A technology for cultivating substrates and cultivation methods, applied in the fields of cultivating substrates and industrialized cultivation of Pleurotus eryngii, which can solve the problems of polluting the environment, increasing the production cost of Pleurotus eryngii, and not being fully utilized, so as to achieve cost reduction and abundant and easy-to-obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

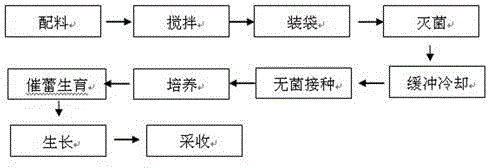

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 A kind of Pleurotus eryngii culture substrate and industrialized cultivation method

[0030] The composition of Pleurotus eryngii culture substrate is: 30% corn cob, 30% bagasse, 10% bran, 10% corn flour, and 20% sawdust; Particles with a size of 0.6 cm; the bran, corn flour, wood chips, and bagasse mentioned above are fresh, free from mildew and insects.

[0031] (1) Ingredients: add water according to the above formula, stir while adding water, the amount of water added is 30%, continue stirring for 120 minutes after adding water; add 0.5% mixed enzyme after adding water, continue stirring for 120 minutes; the mixed enzyme is fiber Sulfase: hemicellulase: α-amylase: glucoamylase=3:1:2:1;

[0032] (2) Bagging and sterilization: Start the bagging machine, pack the mixture into bags, and vacuum three times (after vacuuming, the pressure in the kettle is -0.055 Pa). After the vacuuming, start the sterilization program and start the sterilization process Whe...

Embodiment 2

[0042] Embodiment 2 A kind of Pleurotus eryngii culture substrate and factory culture method

[0043] The composition of Pleurotus eryngii culture substrate is: 20% corn cob, 40% bagasse, 5% bran, 15% corn flour, 20% sawdust; cm-sized particles. The cultivation steps are:

[0044] (1) Ingredients: Mix the above formula, mix and add water, stir while adding water, the amount of water added is 50%, after adding water, add 1.5% mixed enzyme, and continue to stir for 60 min; the mixed enzyme is cellulase: half Cellulase: α-amylase: glucoamylase=3:1:2:1;

[0045] (2) Sterilization by bagging: Start the bagging machine, put the mixture into bags, and vacuum three times. After the vacuuming is completed, start the sterilization process, the sterilization temperature is 121°C, and keep warm for 100 minutes;

[0046] (3) Out of oven cooling: When the temperature is lower than 80°C, out of the oven, put the sterilizing vehicle in the heat insulation buffer room to dissipate heat, and...

Embodiment 3

[0052] Embodiment 3 a kind of Pleurotus eryngii culture substrate and factory culture method

[0053] The composition of Pleurotus eryngii culture substrate is: 40% corn cob, 30% bagasse, 15% bran, 5% corn flour, and 10% sawdust; particle. The cultivation steps are:

[0054] (1) Ingredients: Mix the above formula, mix and add water, stir while adding water, the amount of water added is 45%, after adding water, add 1.0% mixed enzyme, and continue to stir for 90 min; the mixed enzyme is cellulase: half Cellulase: α-amylase: glucoamylase=3:1:2:1;

[0055] (2) Bagging and sterilization: start the bagging machine, pack the mixture into bags, each bag weighs 2600g±20g, vacuumize three times, the pressure inside the kettle is -0.055Pa after vacuuming three times, after vacuuming, start to extinguish Sterilization program, sterilization temperature 121 ℃, heat preservation 110 min;

[0056] (3) Out of oven cooling: When the temperature is lower than 80°C, out of the oven, put the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com