Method for extracting alcohol soluble substance from bark of mongolian pine

A pine bark and alcohol-soluble technology, which is applied in the separation/purification of carboxylic acid compounds, the separation/purification of medical raw materials derived from gymnosperms subphylum, and the separation/purification of carboxylic acid esters can solve the problem of low resource utilization and achieve extraction High efficiency, good separation effect, and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

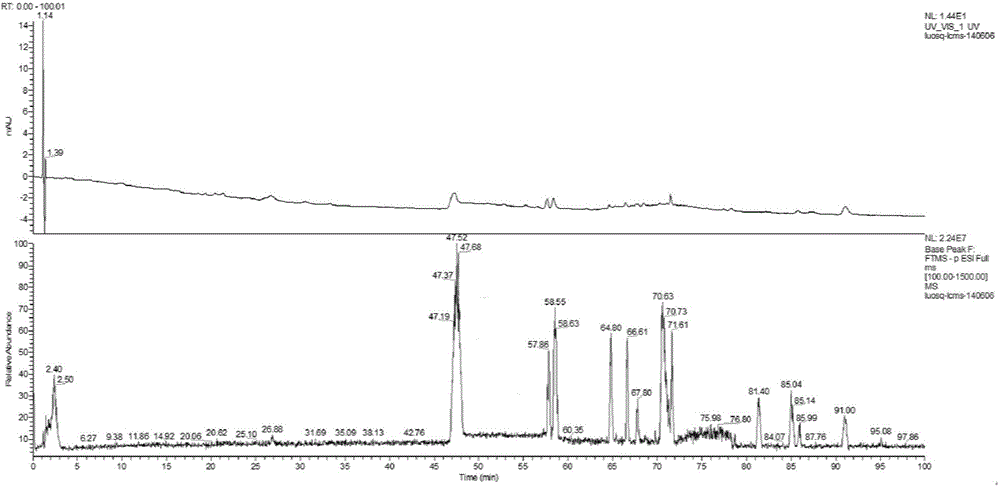

Image

Examples

Embodiment 1

[0028] Embodiment 1 A kind of method of extracting alcohol-soluble substance from Pinus sylvestris sylvestris bark

[0029] Including the following steps:

[0030] (1) Crush 20g of Pinus sylvestris bark into particles of 20-80 mesh size, put it into 300mL of n-hexane / chloroform, the volume ratio of n-hexane to chloroform is 1:5, and apply ultrasonic waves for 30min at 35°C , Ultrasonic frequency is 25KHz.

[0031] (2) vacuum filter the treated mixture while it is hot to obtain filtrate a and filter residue. The filtrate a was placed in a rotary evaporator for vacuum distillation, and the n-hexane / chloroform solvent was distilled off to obtain lipid substances.

[0032] (3) Put the filter residue in step 2) into 400 mL, 50% ethanol solution, and apply ultrasonic wave at 30° C. for 30 min, and the ultrasonic frequency is 19 KHz.

[0033] (4) vacuum filter the treated mixture while hot to obtain filtrate b. The filtrate a was placed in a rotary evaporator for vacuum distillat...

Embodiment 2

[0036] Embodiment 2 A kind of method of extracting alcohol-soluble substance from Pinus sylvestris sylvestris bark

[0037] (1) Crush 20g of Pinus sylvestris bark into particles of 30-60 mesh size, put it into 400mL of n-hexane / chloroform, the volume ratio of n-hexane and chloroform is 1:1, and apply ultrasonic waves for 60min at 50°C , Ultrasonic frequency is 30KHz.

[0038] (2) vacuum filter the treated mixture while it is hot to obtain filtrate a and filter residue. The filtrate a was placed in a rotary evaporator for vacuum distillation, and the n-hexane / chloroform solvent was distilled off to obtain lipid substances.

[0039] (3) Put the filter residue in step 2) into 500 mL of 80% ethanol solution, and apply ultrasonic wave at 35° C. for 60 min, and the ultrasonic frequency is 25 KHz.

[0040] (4) vacuum filter the treated mixture while hot to obtain filtrate b. The filtrate b was concentrated under reduced pressure with a rotary evaporator, and the ethanol solvent wa...

Embodiment 3

[0043] Embodiment 3 A kind of method of extracting alcohol-soluble substance from Pinus sylvestris sylvestris bark

[0044] (1) Crush 20g of Pinus sylvestris bark into particles of 30-70 mesh size, put it into 350mL of n-hexane / chloroform, the volume ratio of n-hexane and chloroform is 1:2, and apply ultrasonic waves for 50min at 40°C , Ultrasonic frequency is 35KHz.

[0045] (2) vacuum filter the treated mixture while it is hot to obtain filtrate a and filter residue. The filtrate a was placed in a rotary evaporator for vacuum distillation, and the n-hexane / chloroform solvent was distilled off to obtain lipid substances.

[0046] (3) Put the filter residue in step 2) into 500 mL of 70% ethanol solution, and apply ultrasonic wave at 30° C. for 55 min, and the ultrasonic frequency is 25 KHz.

[0047] (4) vacuum filter the treated mixture while hot to obtain filtrate b. The filtrate b was concentrated under reduced pressure with a rotary evaporator, and the ethanol solvent wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com