Method for preparing bis(diphenylphosphino)

A bis-diphenylphosphine-alkane and diphenylphosphine-alkane technology, which is applied in the field of synthesis of bidentate phosphine ligands, can solve the problems of difficult large-scale industrial application, complicated operation, complicated equipment, etc., and achieves convenient and simplified operation The effect of small investment in steps and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

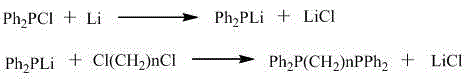

Method used

Image

Examples

Embodiment 1

[0015] Synthesis of Bis-diphenylphosphineethane

[0016] Add 600L tetrahydrofuran and 15kg lithium metal to a 1000L reactor, add 220kg diphenylphosphine chloride dropwise at 20°C, after the reaction of diphenylphosphine chloride is complete, add 49kg 1,2-dichloroethane dropwise at 20°C After the reaction is completed, add 1kg antioxidant 300, remove THF under reduced pressure, add 400L 2M dilute hydrochloric acid, stir, cool, and centrifugally filter. The filter cake is recrystallized with 300L methanol to obtain 189kg white solid bis-diphenylphosphineethane with a purity of 96 %, yield 95%.

Embodiment 2

[0018] Synthesis of bis-diphenylphosphinopropane

[0019] Add 650L tetrahydrofuran and 16kg lithium metal to a 1000L reactor, add 220kg diphenylphosphine chloride dropwise at 60°C, after the reaction of diphenylphosphine chloride is complete, add 56.5kg 1,3-dichloropropane dropwise at 60°C After the reaction was completed, 1.5kg of antioxidant 300 was added, THF was removed under reduced pressure, 450L of 2M dilute hydrochloric acid was added, stirred, cooled, centrifugally filtered, and the filter cake was recrystallized with 350L of methanol to obtain 198kg of white solid bis-diphenylphosphinopropane with a purity of 96 %, yield 96%.

Embodiment 3

[0021] Synthesis of bis-diphenylphosphinobutane

[0022] Add 700L tetrahydrofuran and 15kg lithium metal to a 1000L reactor, add 220kg diphenylphosphine chloride dropwise at 40°C, after the reaction of diphenylphosphine chloride is complete, add 62.5kg 1,4-dichlorobutane dropwise at 50°C Alkanes, after the reaction is completed, add 2kg antioxidant 264, remove tetrahydrofuran under reduced pressure, add 500L 2M dilute hydrochloric acid, stir, cool, and centrifugally filter, and the filter cake is recrystallized with 400L methanol to obtain 207kg white solid bis-diphenylphosphinobutane. 96%, yield 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com