PVDF (polyvinylidene fluoride) modified perfluorosulfonate proton exchange membrane and preparation method thereof

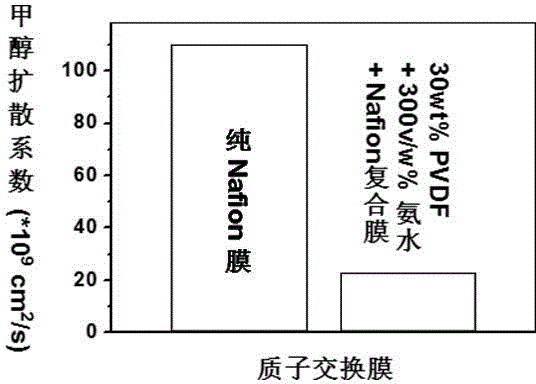

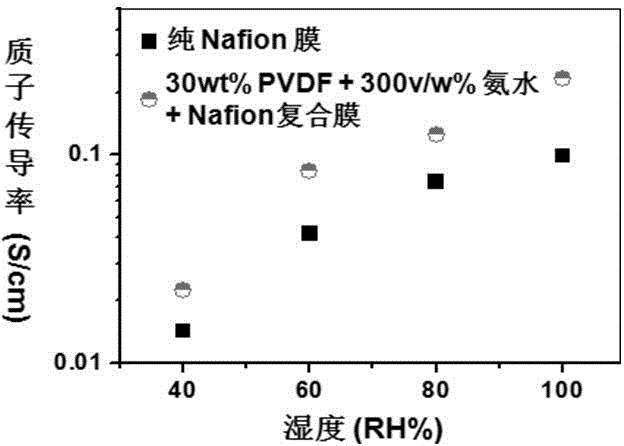

A technology of proton exchange membrane and perfluorosulfonic acid, which is applied in the field of perfluorosulfonic acid proton exchange membrane and its preparation, can solve the problem of decreased proton conductivity of composite proton exchange membrane, difficult scale, industrial production, and complex steps and other issues, to achieve a good industrial production basis, easy to batch, and improve the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Take 4 ml of commercially available Nafion TM Solution, remove more than half of the solvent by rotary evaporation, then add 3 ml N,N-dimethylformamide, and continue rotary evaporation for 10 min. To the above Nafion TM Add 60 mg PVDF to the solution and sonicate for 1 hour to make it uniformly dispersed;

[0025] 2. Subsequently, add 600 ml of commercially available ammonia solution to the above mixed solution, and then ultrasonically mix it evenly;

[0026] 3. Next, carefully pour the dispersion into the mold and quickly place it at 70 o In C oven, start from 70 °C for 2 h and then slowly increase the temperature to 120 °C to remove the solvent; vacuumize, set the temperature of the vacuum oven at 120 °C and keep it for 16 h;

[0027] 4. Finally, the membrane was first treated with 3 wt% H 2 o 2 solution at 70 o C for 2 h, followed by 1 M H 2 SO 4 Convert the membrane to H at 80 °C for 1 h + type, and finally PVDF modified Nafion can be obtained TM proton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com